Course navigation

-

Unit 1 - Create a 2D Design

Unit 2 - Set up Toolpaths from a 2D Design

1—Set up an inner profile toolpath

2—Set up Toolpaths from a 2D Design

3—Set up a cut-out profile toolpath

4—Checkpoint!

Unit 3 - Have a go at CNC Milling

Unit 4 - Create a 3D file for CNC Milling

Unit 5 - Import your Files for 3D Milling

Unit 6 - Set up Toolpaths for 3D Milling

Set up a cut-out profile toolpath

Practise setting up an outer profile toolpath to cut out the shape of your desk tidy then save your VCarve document in the appropriate file format.

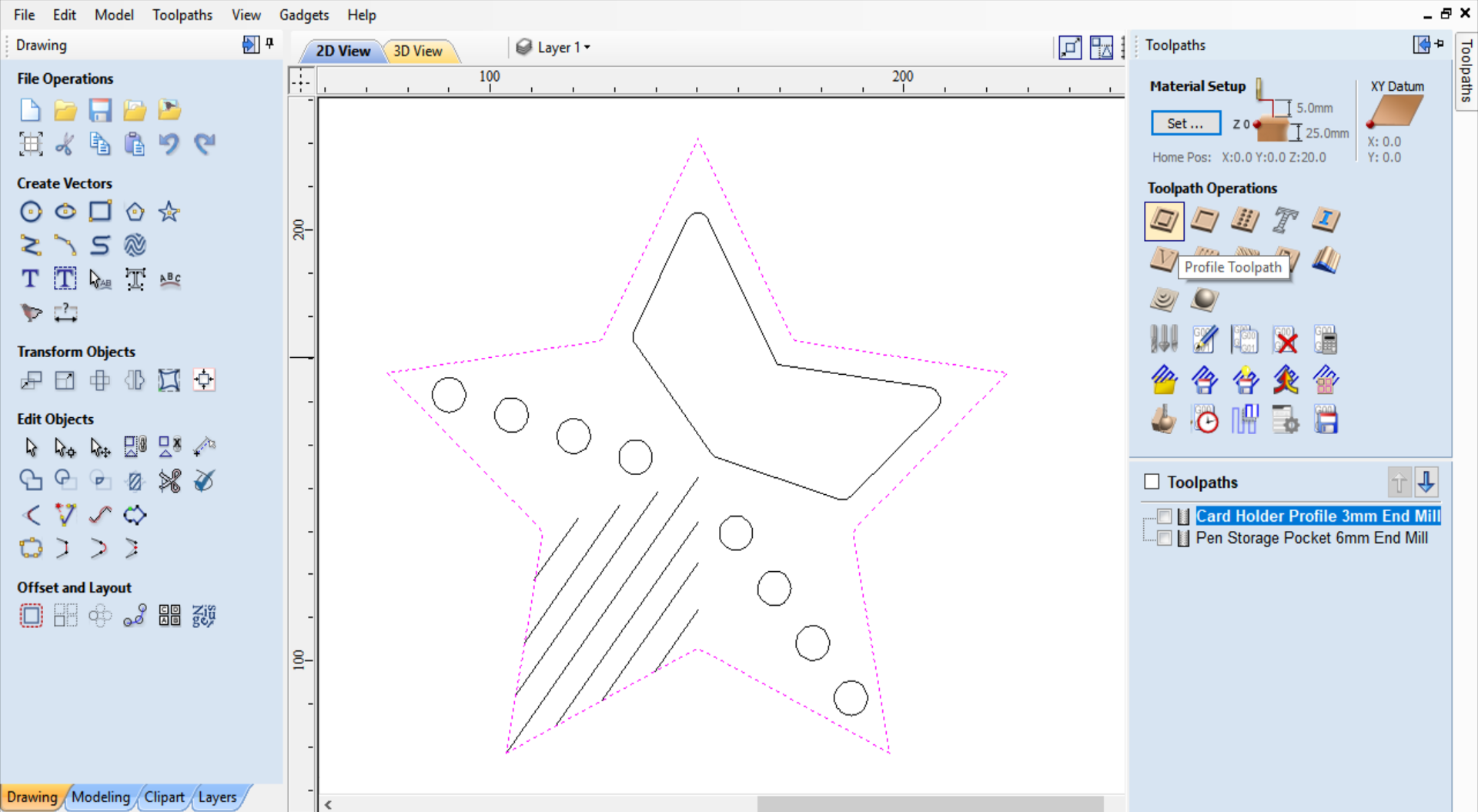

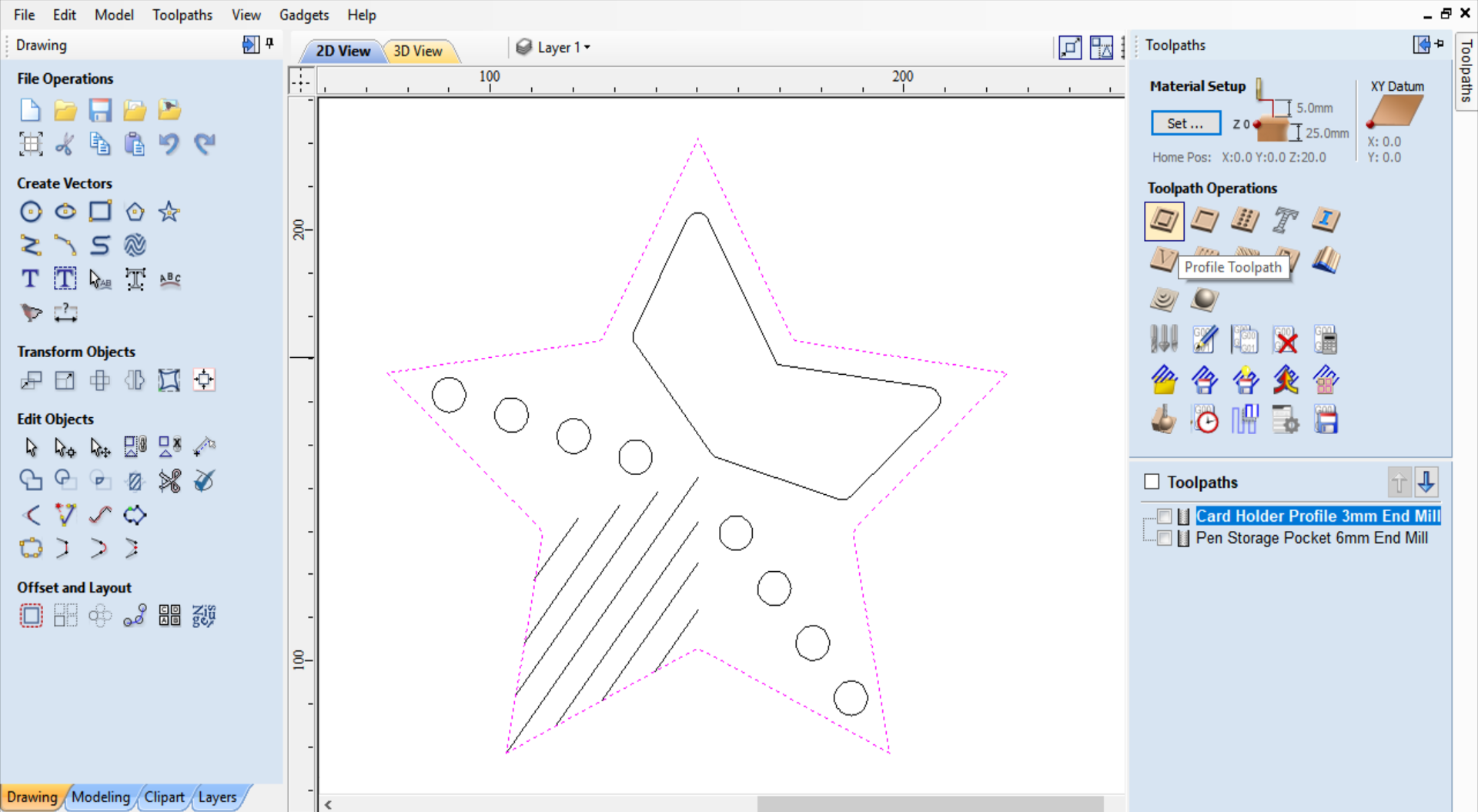

Close the 3D preview and switch the tab from 3D View to 2D View at the top of your document. Select your outer cut vector then go to Toolpaths and click on Profile Toolpath.

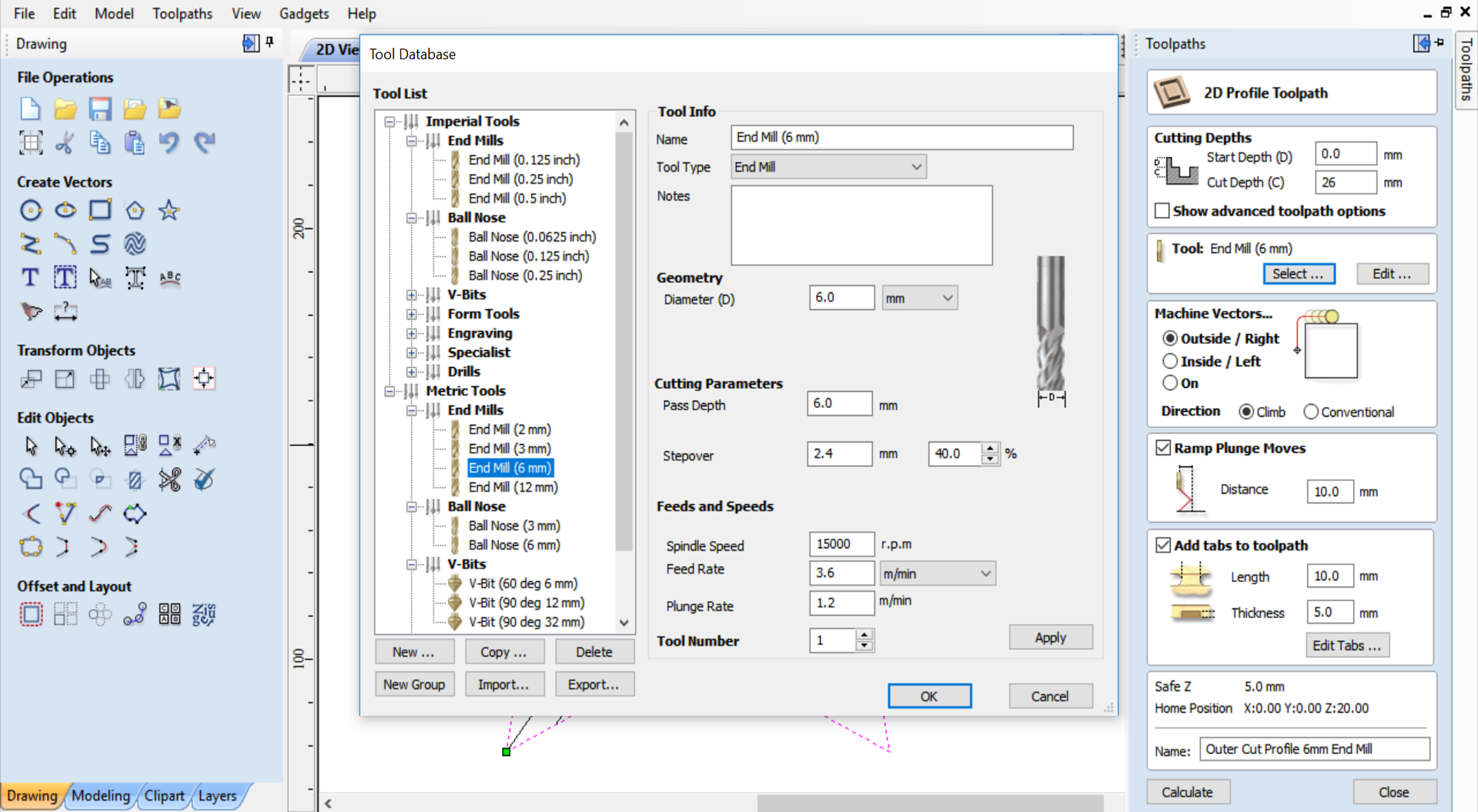

When the Profile Toolpath menu opens, go to Tool and click on Select to choose your cutter and settings.

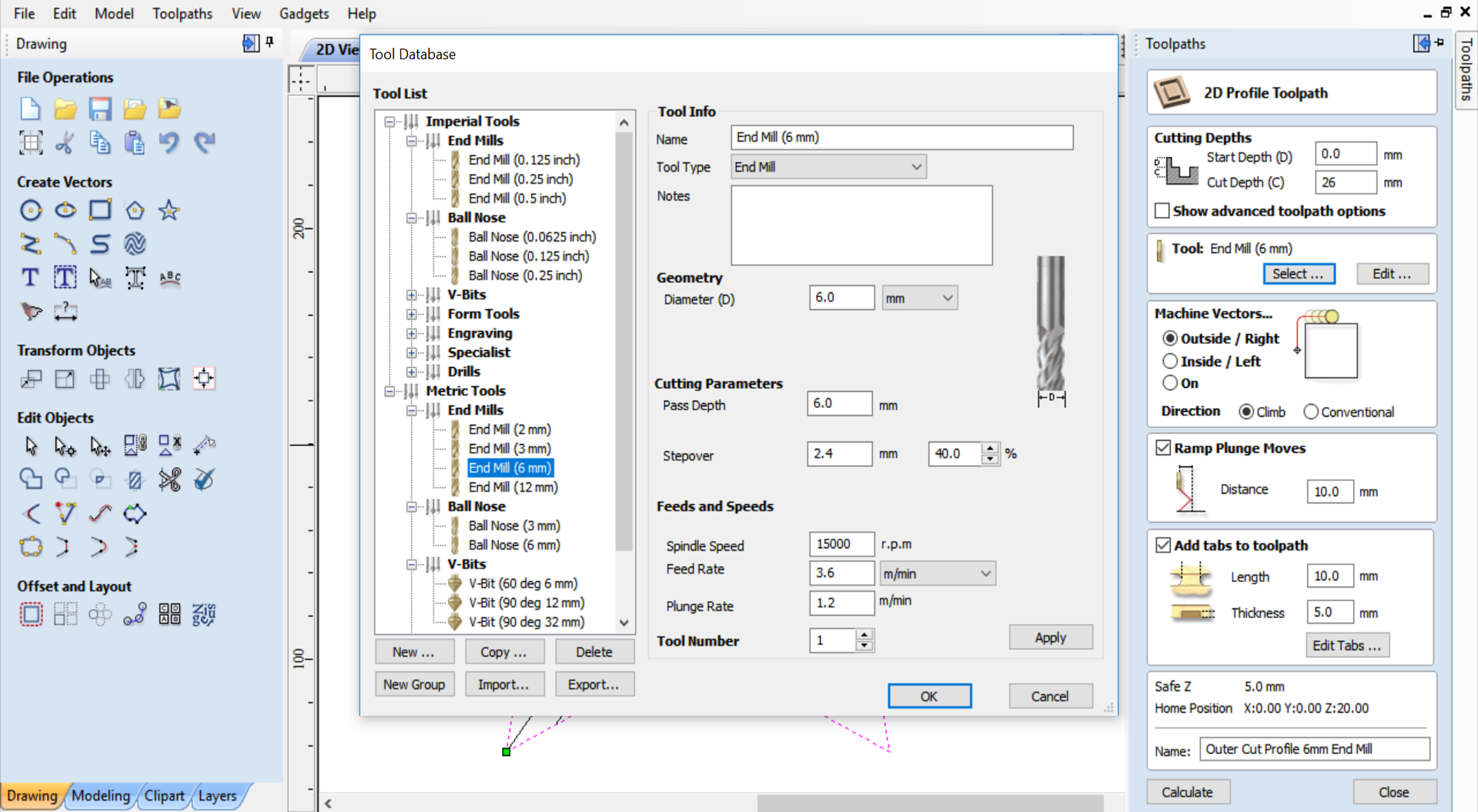

In the Tool List, go to Metric Tools and select the 6mm End Mill. (This toolpath is your deepest cutting toolpath. You want to use a larger tool for your deeper cuts because as a general rule, larger cutters will have longer cutting flutes, are more rigid and less likely to create deflection when cutting into a material)

Enter the following settings:

In Cutting Parameters

In Feeds and Speeds

Once you’ve entered these settings, select Apply and OK to return to your Profile Toolpath settings.

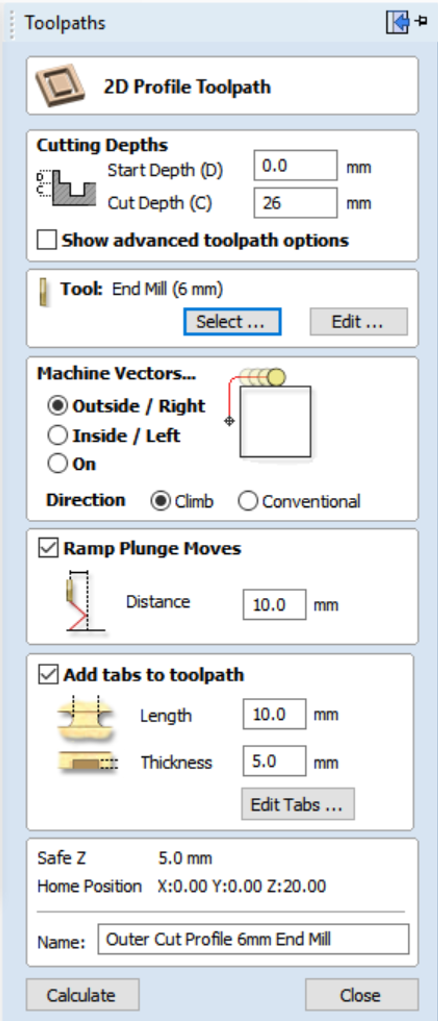

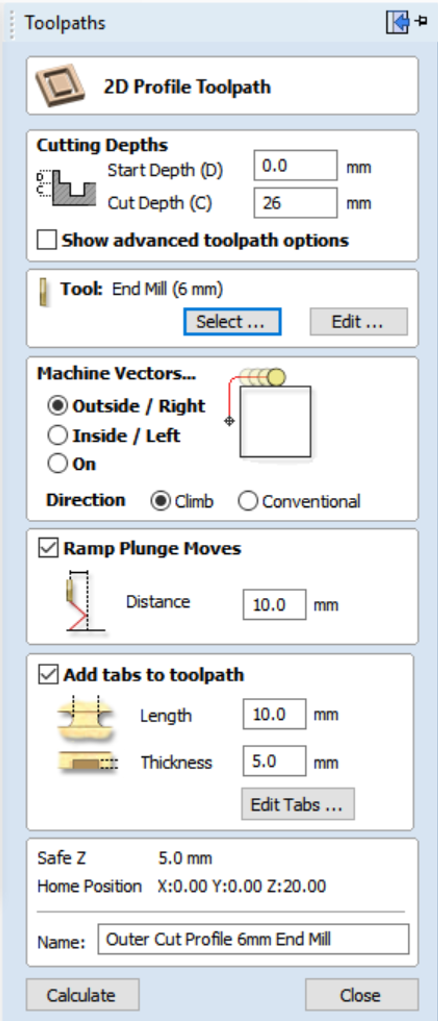

In Cutting Depths

In Machine Vectors

Select Ramp Plunge and set the distance to 10mm.

Select Add Tabs, set the length to 10mm and the thickness to 5mm, then select Edit Tabs. (Tabs allow you to hold your material in place while you complete your cut out toolpath so the work piece won’t move position and dislodge itself as you complete your cut. Without using tabs you risk causing injury or damaging the equipment. All outer cut toolpaths must use tabs.)

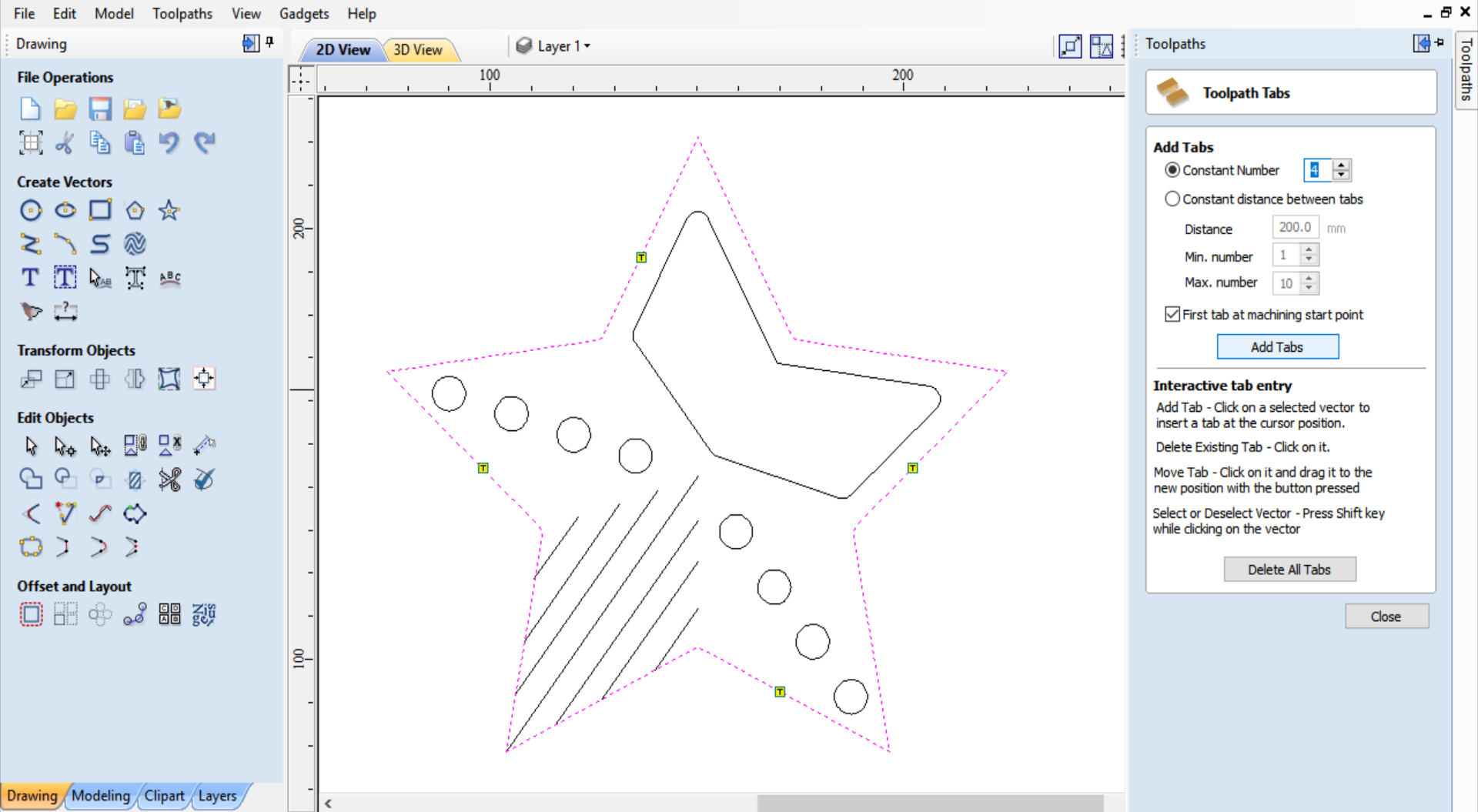

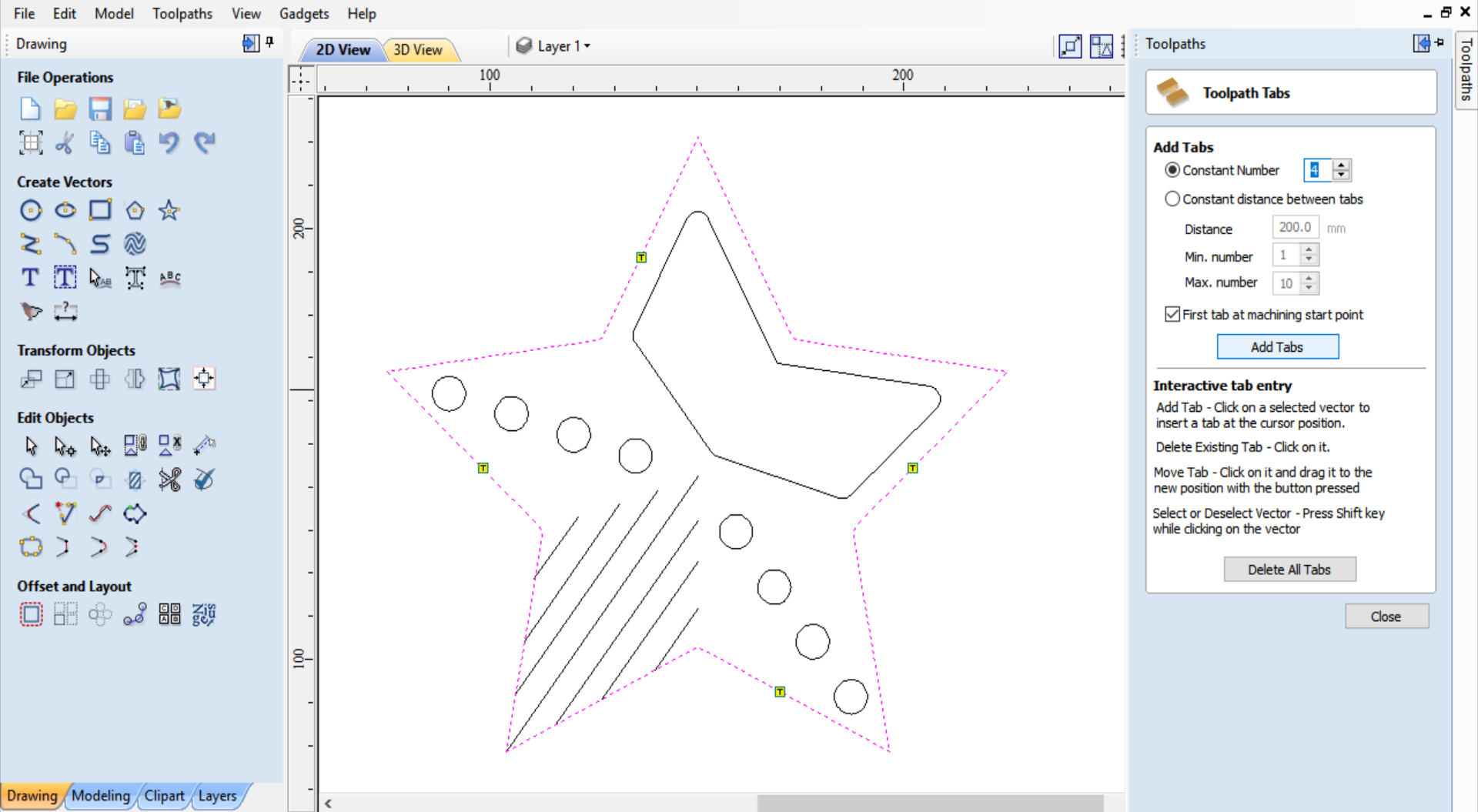

In the Tabs dialogue box, set the Constant Number to 4 then select Add Tabs. The Tabs will show as little yellow boxes with a T. If you select and drag one while the tabs dialogue box is open, you can move its position up and down. Make sure to position all 4 tabs away from any corners or round sections and try positioning them on flat parts of the vector if possible. (All tabs will be cut off and sanded back once the design is cut out.)

Finally name your toolpath using the same naming conventions. Your toolpath will be called “Outer Cut Profile 6mm End Mill”. Remember to add your initials at the start of the name to differentiate your toolpaths from the other workshops participants’ toolpaths.

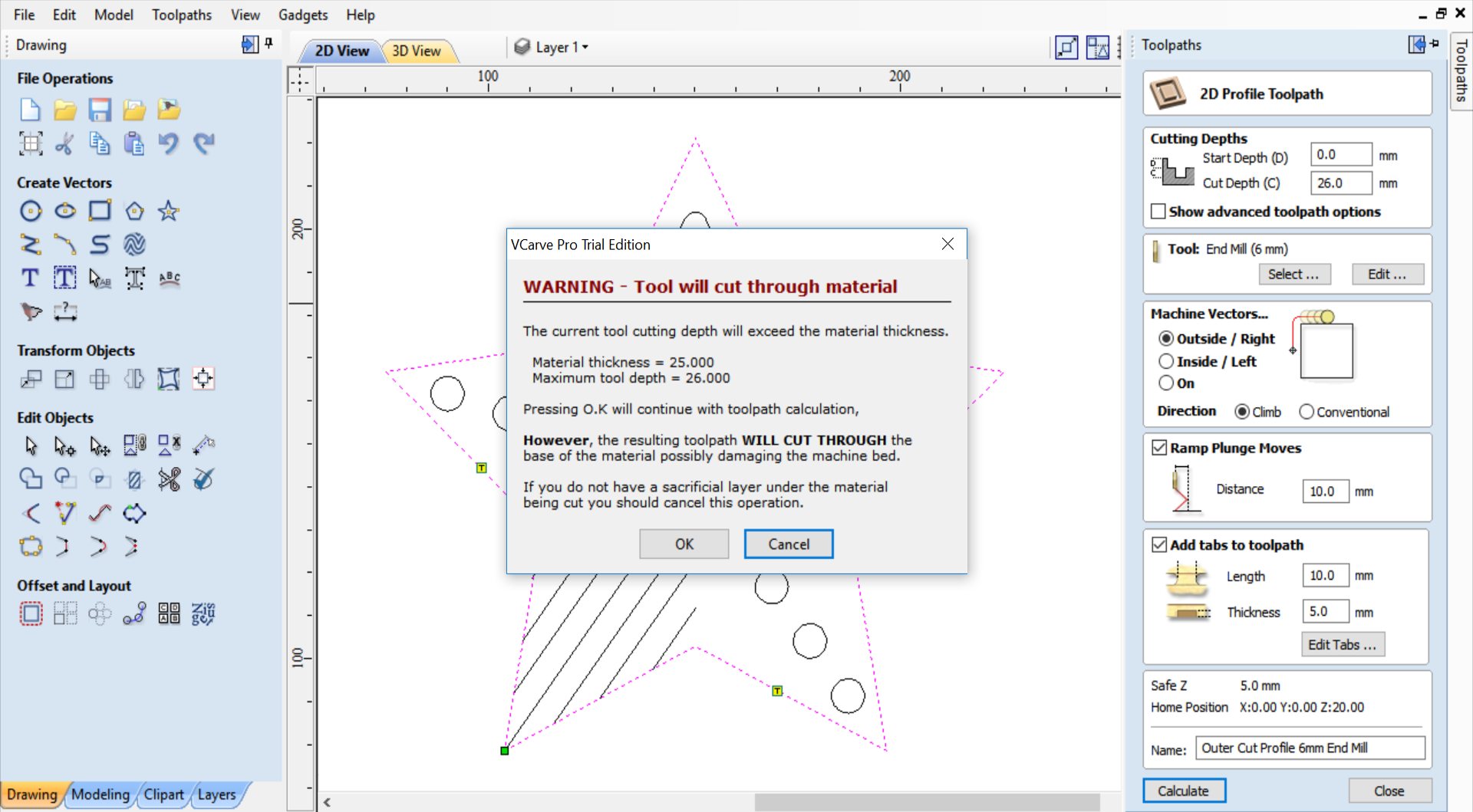

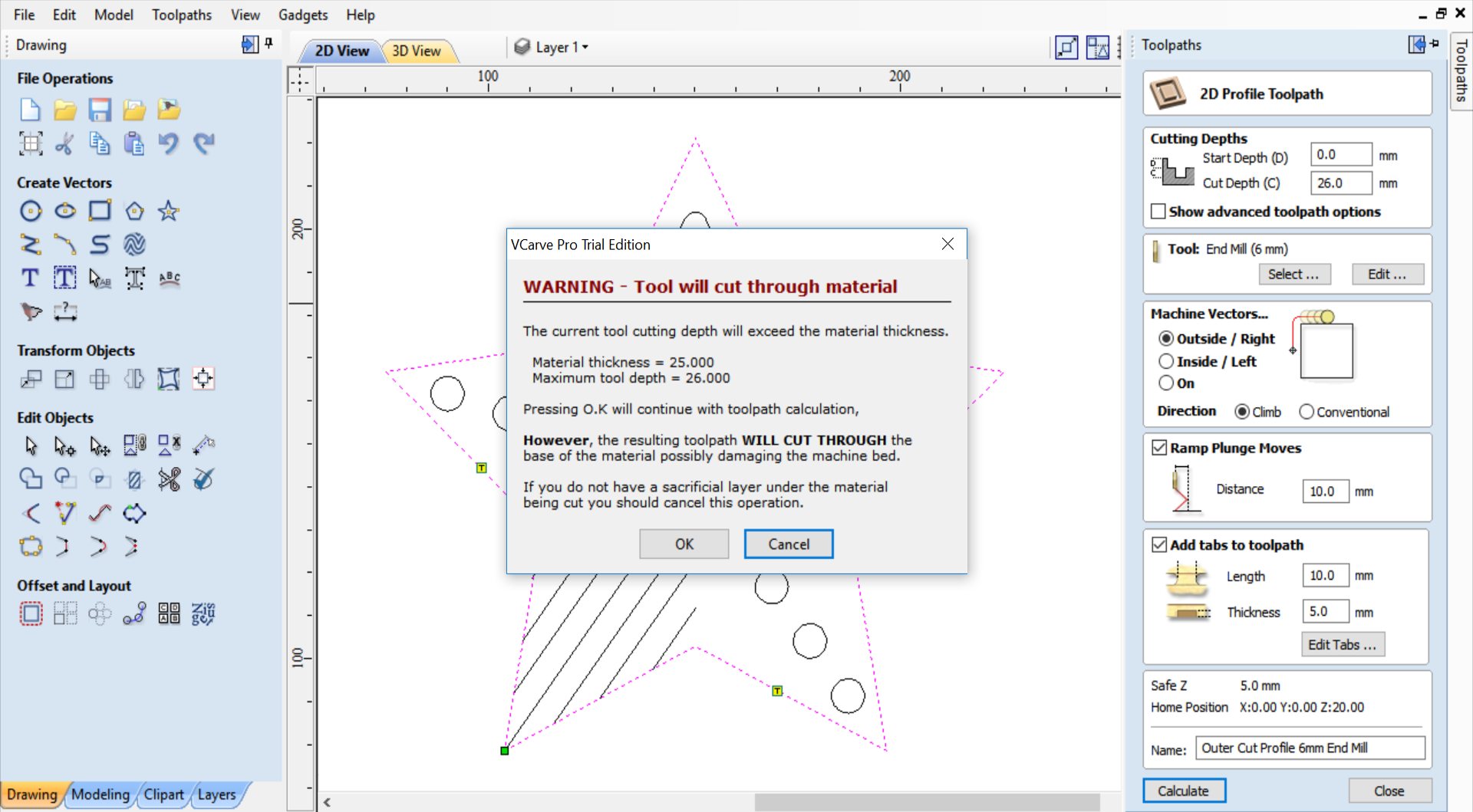

Once you’ve named it, press Calculate to complete your settings. A warning will come up to inform you that your tool will cut all the way through. Select OK to allow the toolpath to complete.

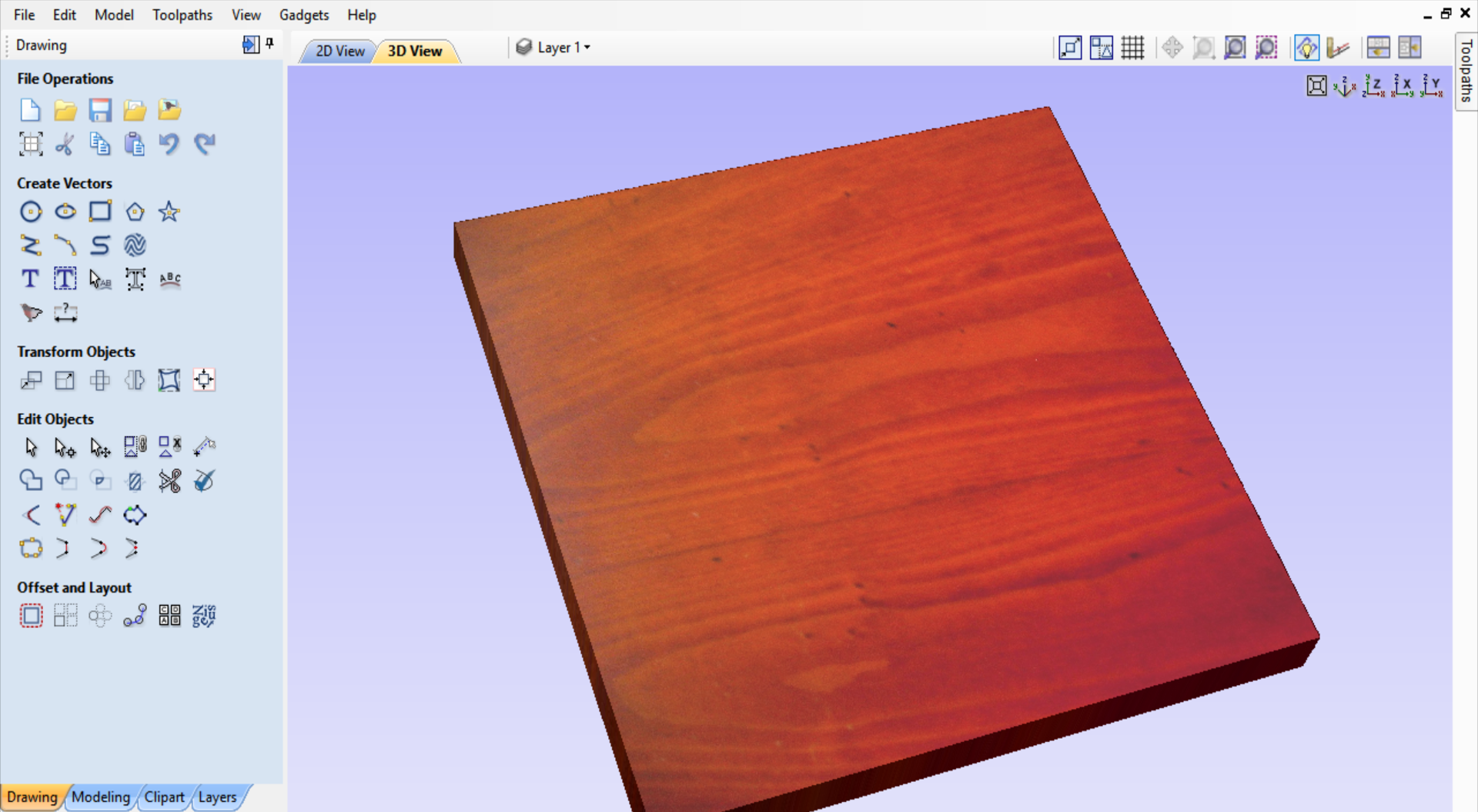

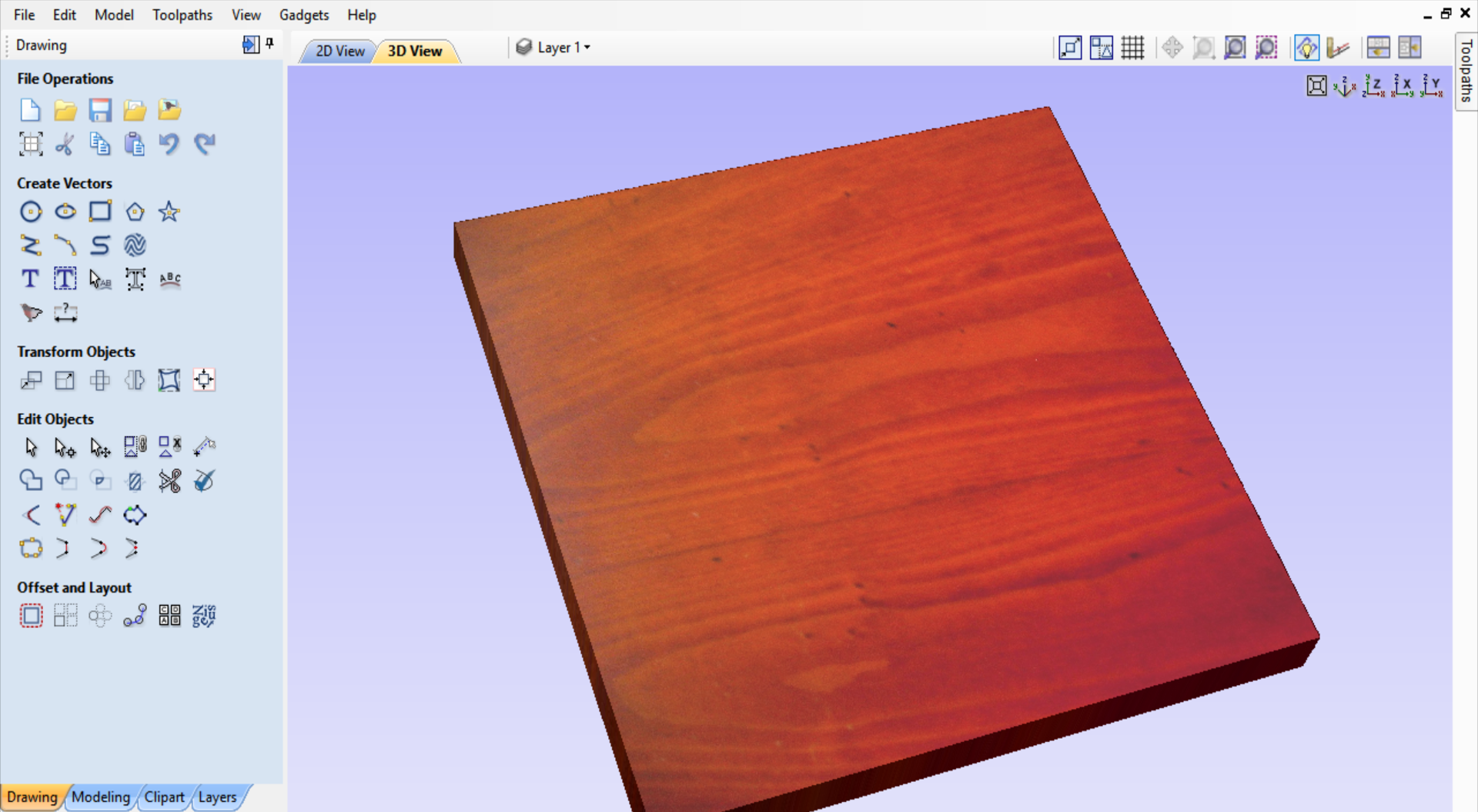

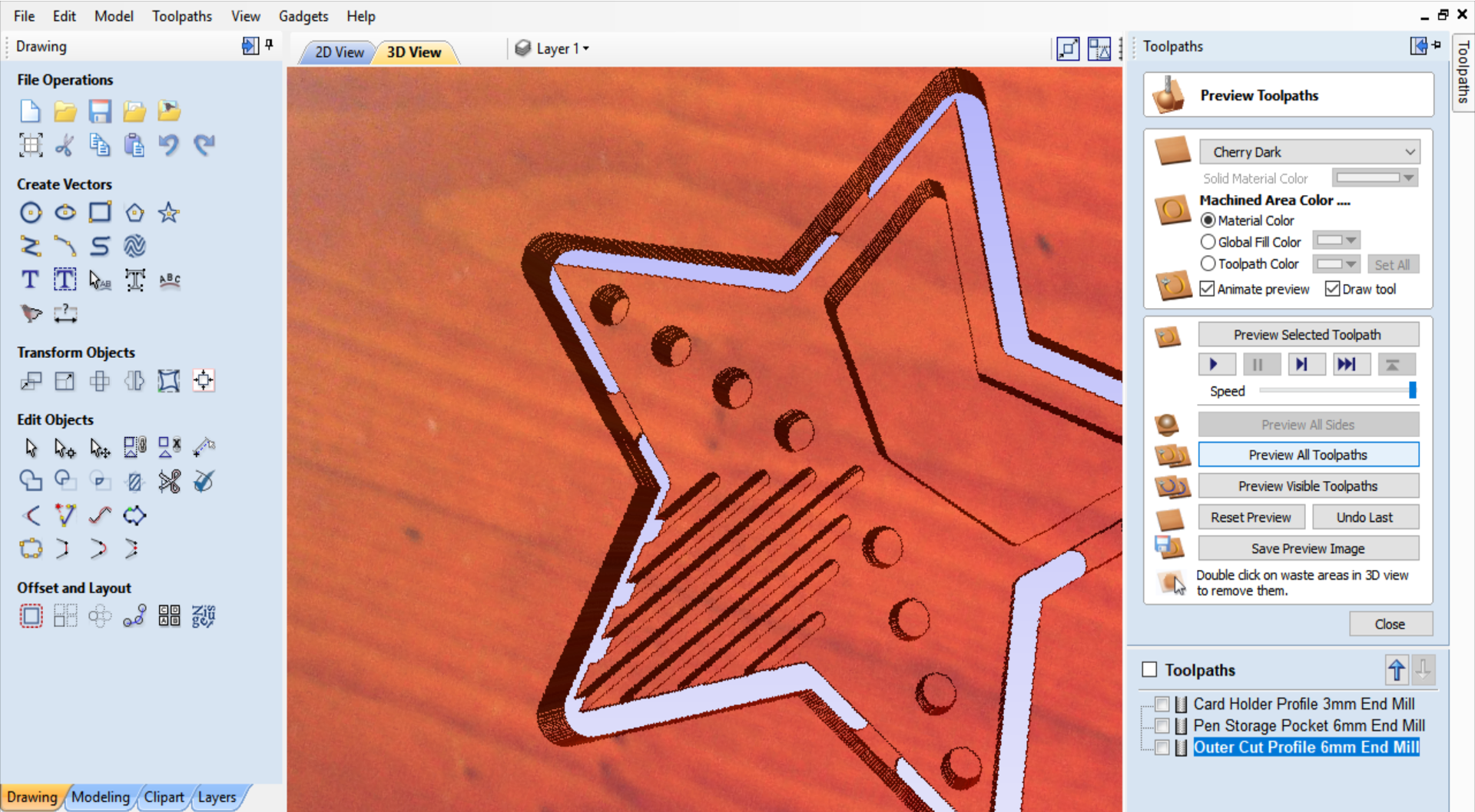

First set your preview material in isometric view in the top right-hand menu.

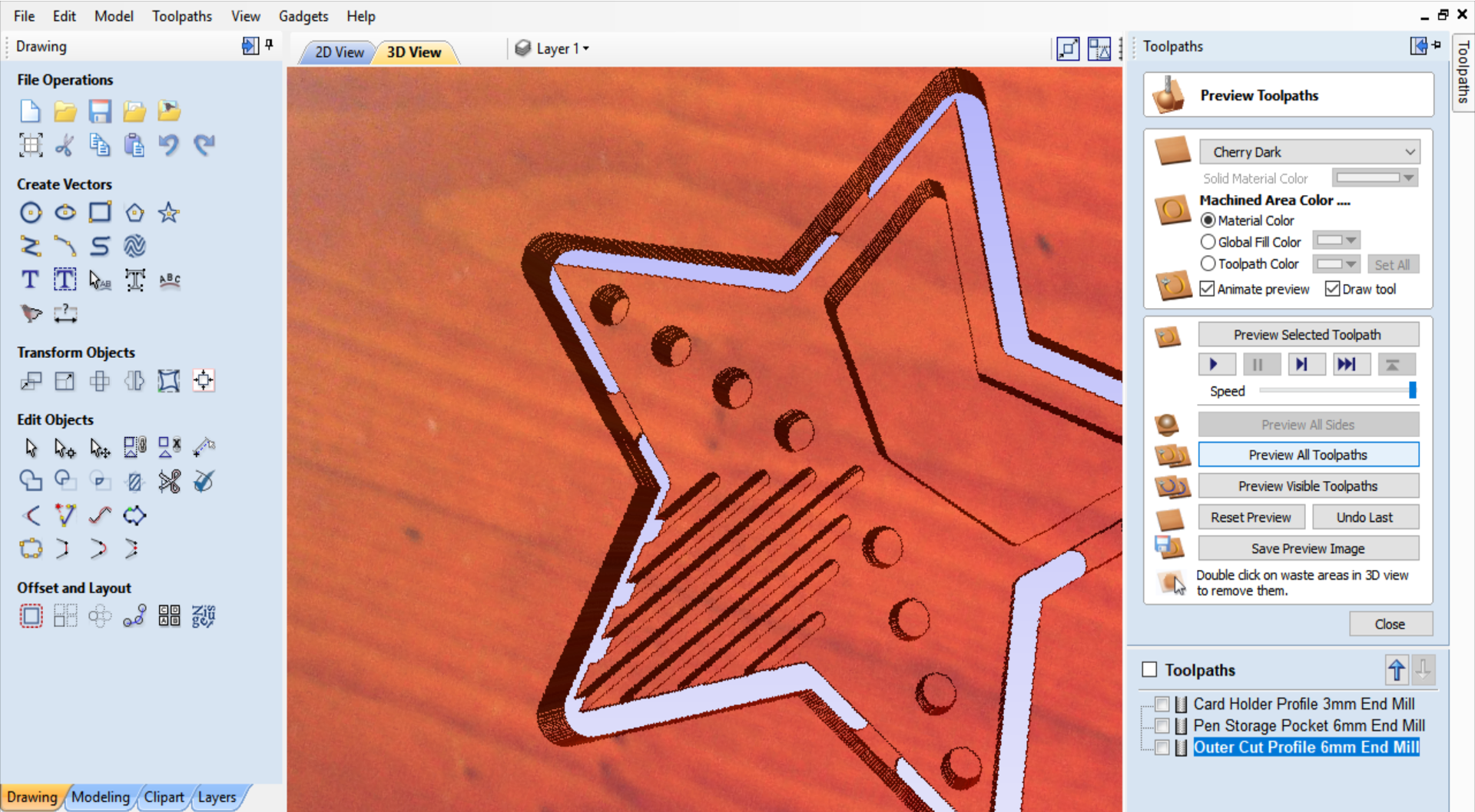

Once you’ve set up the correct view, select Preview all Toolpaths in the Preview Toolpaths menu. You should now have a preview of your toolpaths as they will cut in the material. Check that all the toolpaths look the way you expect them to.

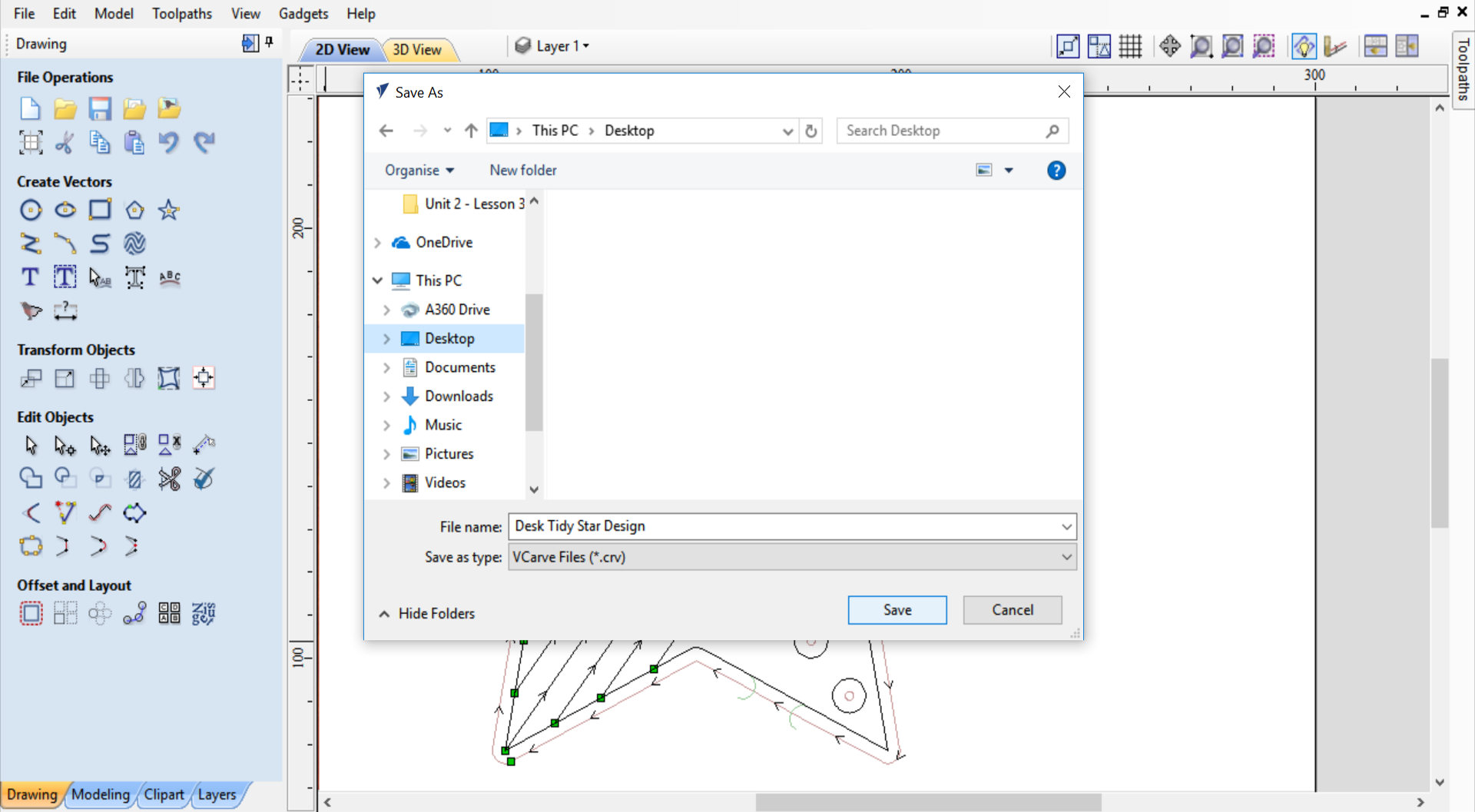

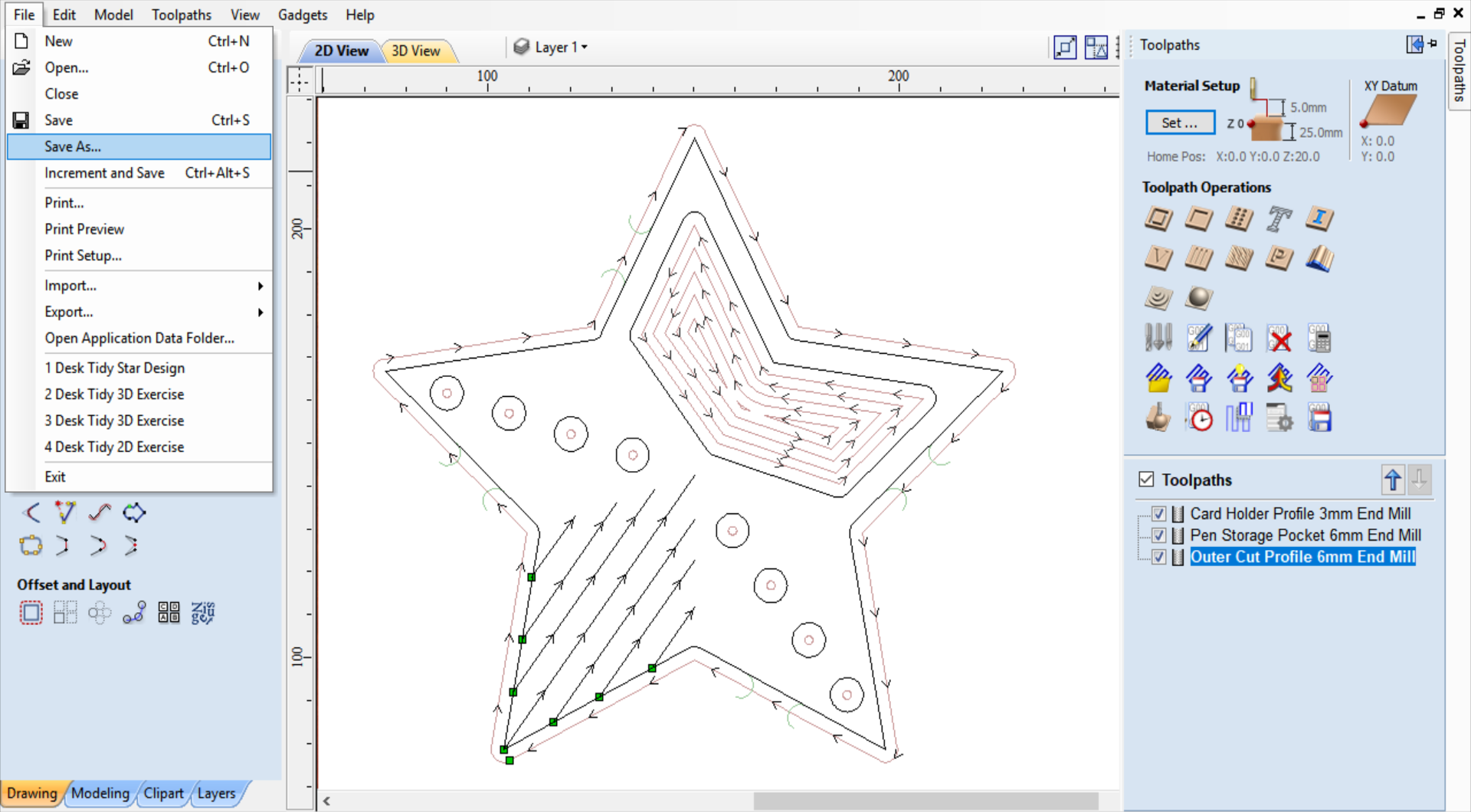

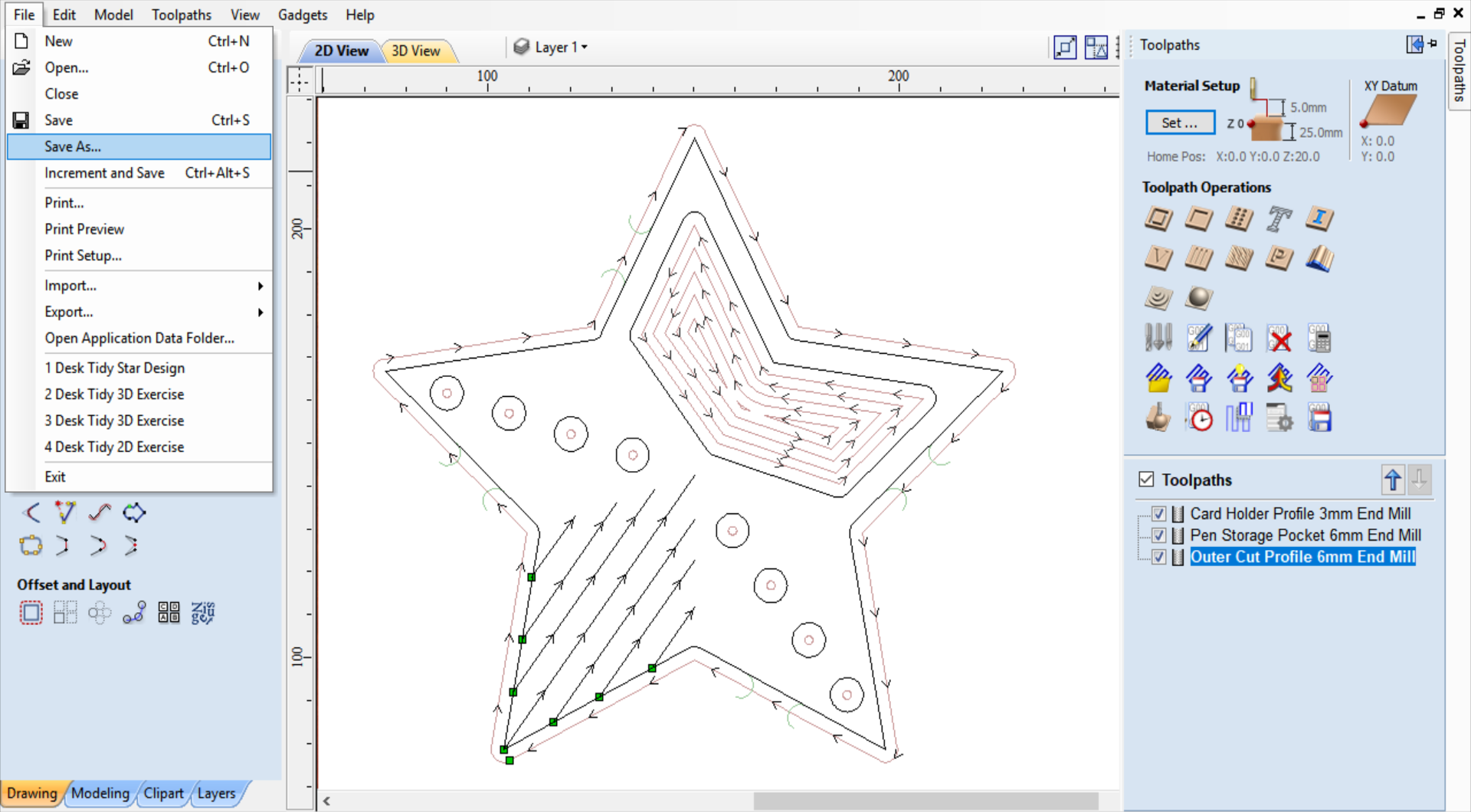

If you’re satisfied with your toolpaths, it is now time to save your design and toolpaths in a VCarve project file, ready to transfer to the CNC Mill control computer. First go to File and Save As.

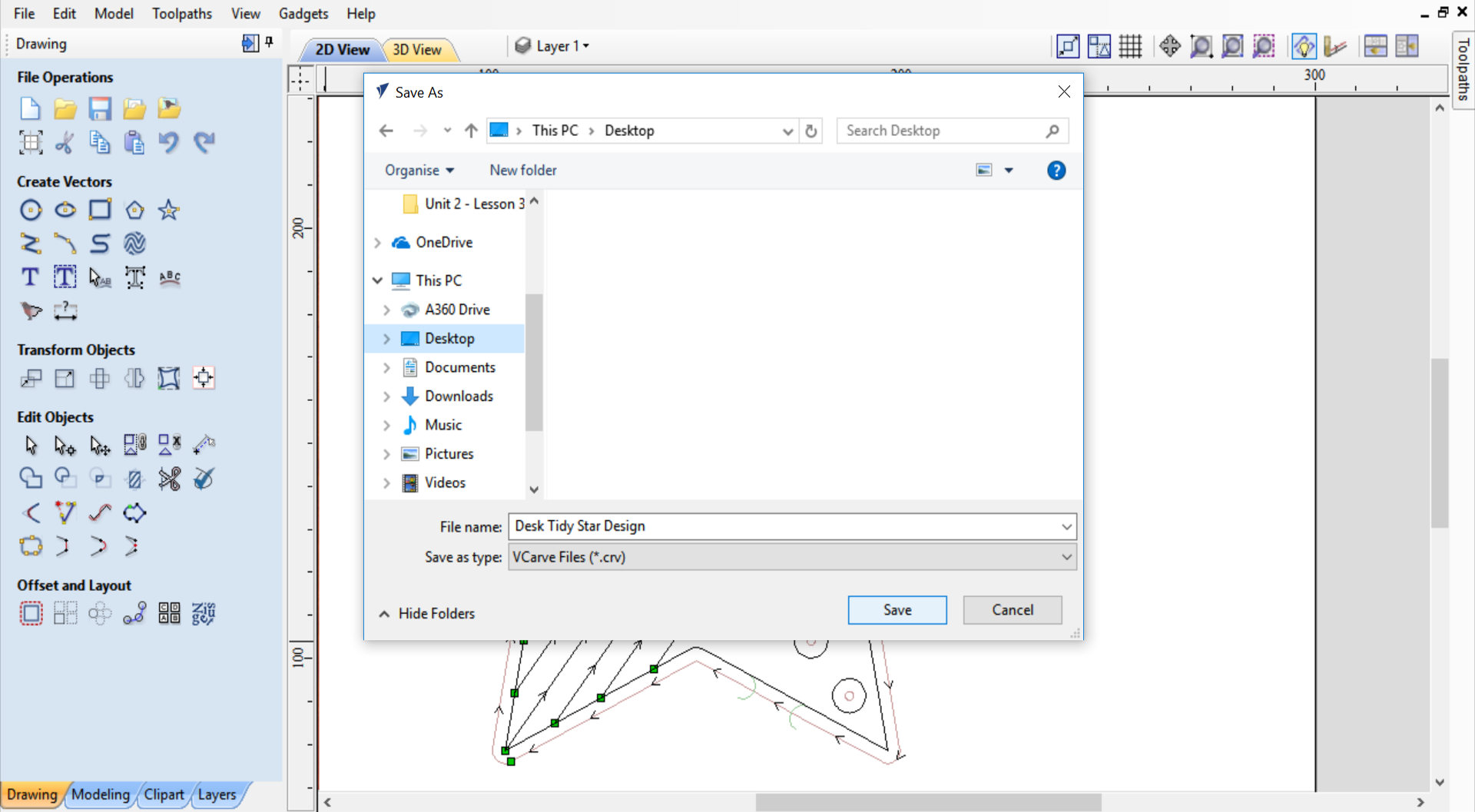

Save your file on the desktop with a memorable name.

Step 1

Close the 3D preview and switch the tab from 3D View to 2D View at the top of your document. Select your outer cut vector then go to Toolpaths and click on Profile Toolpath.

When the Profile Toolpath menu opens, go to Tool and click on Select to choose your cutter and settings.

In the Tool List, go to Metric Tools and select the 6mm End Mill. (This toolpath is your deepest cutting toolpath. You want to use a larger tool for your deeper cuts because as a general rule, larger cutters will have longer cutting flutes, are more rigid and less likely to create deflection when cutting into a material)

Enter the following settings:

In Cutting Parameters

- Pass Depth = 6mm

- Stepover = 40%

In Feeds and Speeds

- Spindle Speed = 15000 rpm

- Feed Rate = 3.6m/min

- Plunge Rate = 1.2m/min

Once you’ve entered these settings, select Apply and OK to return to your Profile Toolpath settings.

Step 2

To complete the rest of your Profile Toolpath, enter the following settings:

In Cutting Depths

- Start Depth = 0mm

- Cut Depth = 26mm (To cut all the way through your material, you need to set the material thickness + 1mm. This should only be done when using a sacrificial board to cut into to avoid the tool cutting past the material into the bed of the bed machine.)

In Machine Vectors

- Select Outside/Right (The cutter will position itself on the outer side of the line to cut round the selected vector)

- Leave the Direction on Climb as default.

Select Ramp Plunge and set the distance to 10mm.

Select Add Tabs, set the length to 10mm and the thickness to 5mm, then select Edit Tabs. (Tabs allow you to hold your material in place while you complete your cut out toolpath so the work piece won’t move position and dislodge itself as you complete your cut. Without using tabs you risk causing injury or damaging the equipment. All outer cut toolpaths must use tabs.)

In the Tabs dialogue box, set the Constant Number to 4 then select Add Tabs. The Tabs will show as little yellow boxes with a T. If you select and drag one while the tabs dialogue box is open, you can move its position up and down. Make sure to position all 4 tabs away from any corners or round sections and try positioning them on flat parts of the vector if possible. (All tabs will be cut off and sanded back once the design is cut out.)

Finally name your toolpath using the same naming conventions. Your toolpath will be called “Outer Cut Profile 6mm End Mill”. Remember to add your initials at the start of the name to differentiate your toolpaths from the other workshops participants’ toolpaths.

Once you’ve named it, press Calculate to complete your settings. A warning will come up to inform you that your tool will cut all the way through. Select OK to allow the toolpath to complete.

Step 3

To double-check your toolpaths, we recommend that you now preview your toolpaths using Preview Toolpaths, which opens automatically upon completing a toolpath.First set your preview material in isometric view in the top right-hand menu.

Once you’ve set up the correct view, select Preview all Toolpaths in the Preview Toolpaths menu. You should now have a preview of your toolpaths as they will cut in the material. Check that all the toolpaths look the way you expect them to.

If you’re satisfied with your toolpaths, it is now time to save your design and toolpaths in a VCarve project file, ready to transfer to the CNC Mill control computer. First go to File and Save As.

Save your file on the desktop with a memorable name.