Course navigation

-

Unit 1 - Create a 2D Design

Unit 2 - Set up Toolpaths from a 2D Design

1—Set up an inner profile toolpath

2—Set up Toolpaths from a 2D Design

3—Set up a cut-out profile toolpath

4—Checkpoint!

Unit 3 - Have a go at CNC Milling

Unit 4 - Create a 3D file for CNC Milling

Unit 5 - Import your Files for 3D Milling

Unit 6 - Set up Toolpaths for 3D Milling

Set up an inner profile toolpath

Practise setting up an inner profile toolpath to create recesses for your desk tidy’s card holder.

Each toolpath is generated in relation to a selected vector or set of vectors in your 2D design. There are two main types of toolpaths you can generate from a design: Profile toolpaths and Pocket toolpaths.

A Profile toolpath is used to direct a CNC mill to use a selected tool to cut along a selected vector line down to a set depth. A Pocket toolpath can only be used with a closed vector and will direct the CNC to clear the area delimited by the closed vector down to a set depth.

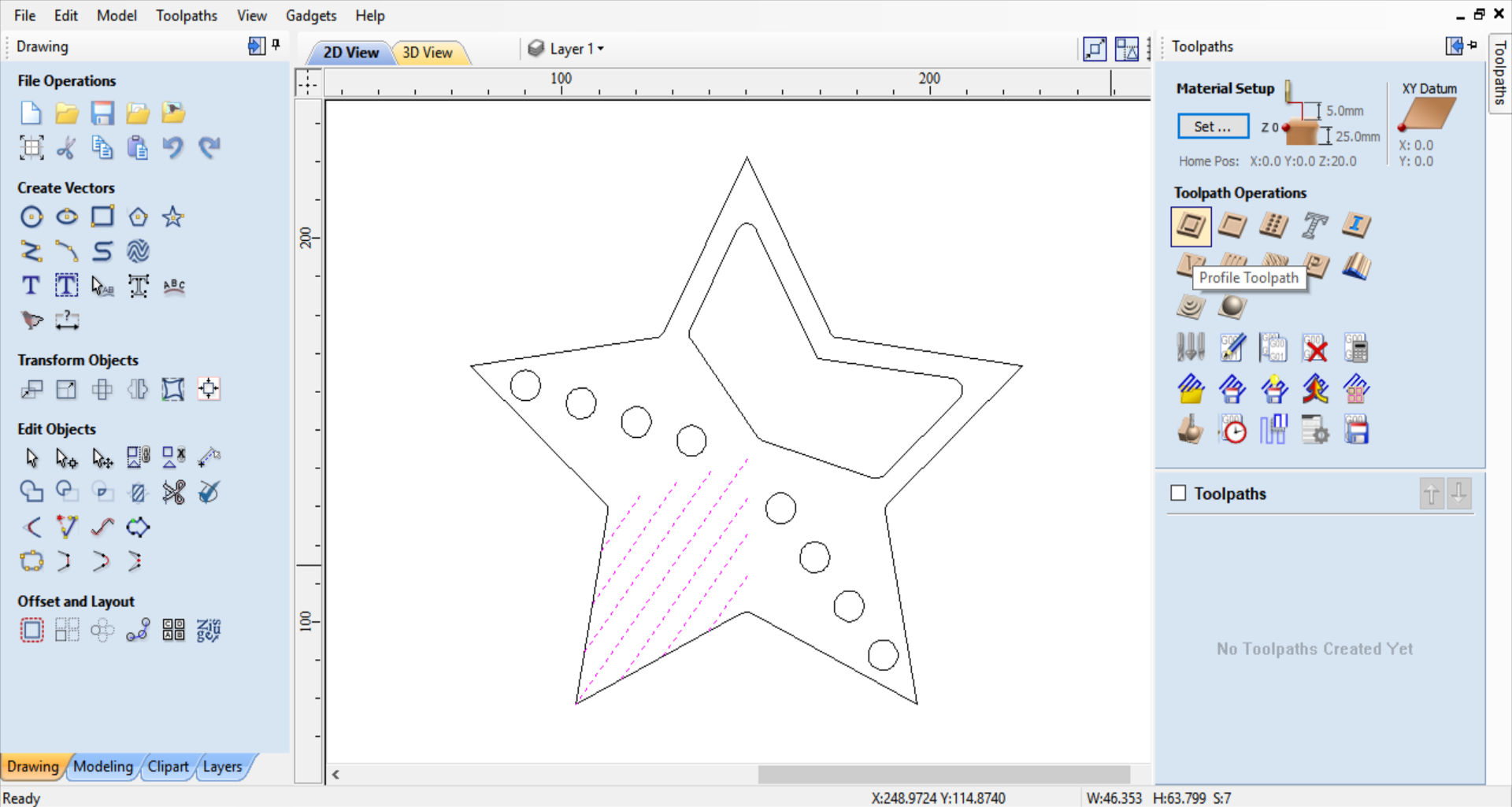

Have a go now and create your first profile toolpath. Select all the lines you designed for your card holder then select Profile toolpath in the right-hand side Toolpath menu under Toolpath Operations.

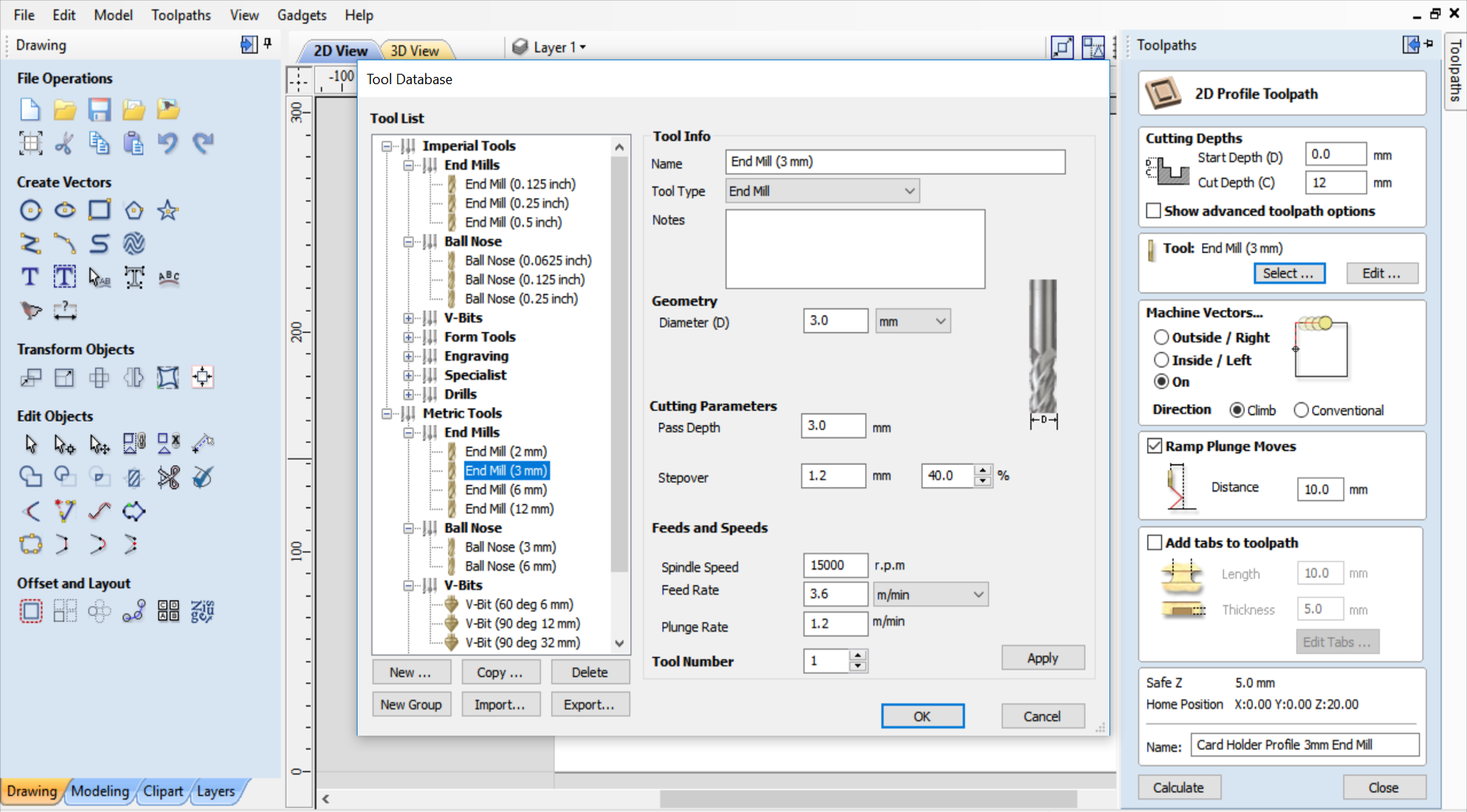

In the Tool List, go to Metric Tools and select the 3mm End Mill, then enter the following settings:

In Cutting Parameters

Pass Depth = 3mm (Determines how deep the tool will cut with each pass)

Stepover = 40% (Use 40% as default setting. The stepover is the distance between toolpath centre lines, mostly used for pocket toolpaths and 3D milling)

In Feeds and Speeds

Spindle Speed = 15000 rpm (Spindle speed is the constant speed with which a cutter spins on its axis in the tool holder. It is calculated in revolutions per minute)

Feed Rate = 3.6m/min (Feed rate is the speed at which a cutter moves forward on the horizontal plane. Feed rates can be set in a variety of units of measurement, make sure that yours is set to m/min)

Plunge Rate = 1.2m/min (Plunge rate is the speed at which a cutter travels up and down on the vertical plane. It uses the same unit of measurement as the feed rate)

Once you’ve entered these settings, select Apply and OK to return to your Profile Toolpath settings.

The Cutting Parameters and Speeds and Feeds should always be carefully balanced and calibrated to produce the most efficient cut for your material. Efficient in this case means removing the most amount of material in the least amount of time whilst preserving the longevity of your tools and preventing them from getting blunted.

All the speeds and feeds in this course are set for cutting Necuron foam on a Roland MDX-50. If you wish to cut other materials in future, please refer to advice from a technician for speeds and feeds.

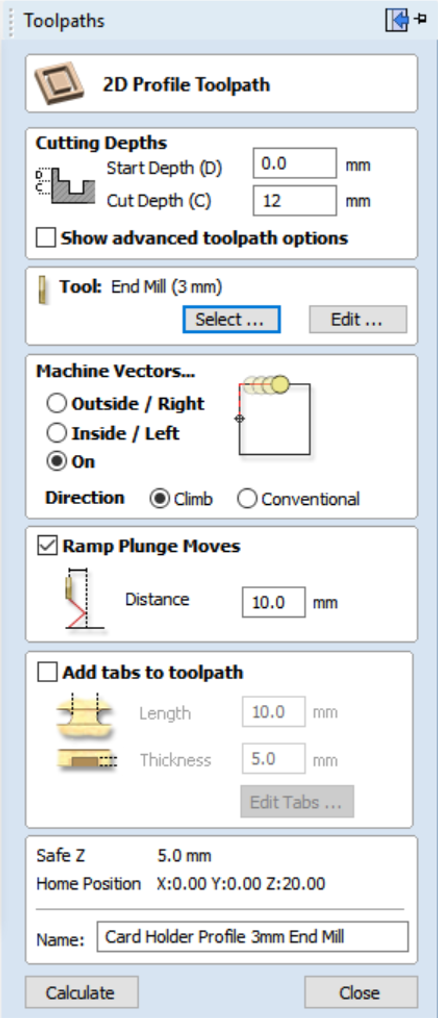

In Cutting Depths

Start Depth = 0mm (Start Depth is the starting point of your toolpath and should always be at the top surface of your material)

Cut Depth = 12mm (Cut Depth determines how deep you want your toolpath to cut. In this case, our material is 25mm deep and we only want to cut part of the way for our recess)

In Machine Vectors

Select On the Line (The cutter will follow the vector lines using its central axis as the point of reference)

Leave the Direction on Climb as default (Climb and Conventional determine whether the cutter follows toolpaths in a clockwise or anti-clockwise direction. This can be useful when working with wood to direct your cutter to work in the direction of the grain of the wood)

Select Ramp Plunge and set the distance to 10mm. (This setting means that rather than cutting straight down to the full cut depth, the cutter will ramp its entry incrementally into the material over a 10mm length until it has reached the cutting depth then start cutting forward. It is good practise to use a ramp plunge and will increase the longevity of your tools).

Finally name your toolpath. As you will create multiple toolpaths in the same file, it is important to adopt good naming conventions. We suggest you use the following naming convention: Description/Purpose + Toolpath Type + Cutter Size and Type. Your toolpath will be called “Card Holder Profile 3mm End Mill”. To differentiate your toolpaths from the other workshops participants’ toolpaths, also add your initials at the start of the name.

Once you’ve named it, press Calculate to complete your settings.

Step 1

The CNC mill can use a wide range of cutters and follow a number of different commands and operations to cut through material and create your designs. To instruct the CNC mill on which operation we want it to carry out and which cutter we will be using for that operation, we need to generate toolpaths.Each toolpath is generated in relation to a selected vector or set of vectors in your 2D design. There are two main types of toolpaths you can generate from a design: Profile toolpaths and Pocket toolpaths.

A Profile toolpath is used to direct a CNC mill to use a selected tool to cut along a selected vector line down to a set depth. A Pocket toolpath can only be used with a closed vector and will direct the CNC to clear the area delimited by the closed vector down to a set depth.

Have a go now and create your first profile toolpath. Select all the lines you designed for your card holder then select Profile toolpath in the right-hand side Toolpath menu under Toolpath Operations.

Step 2

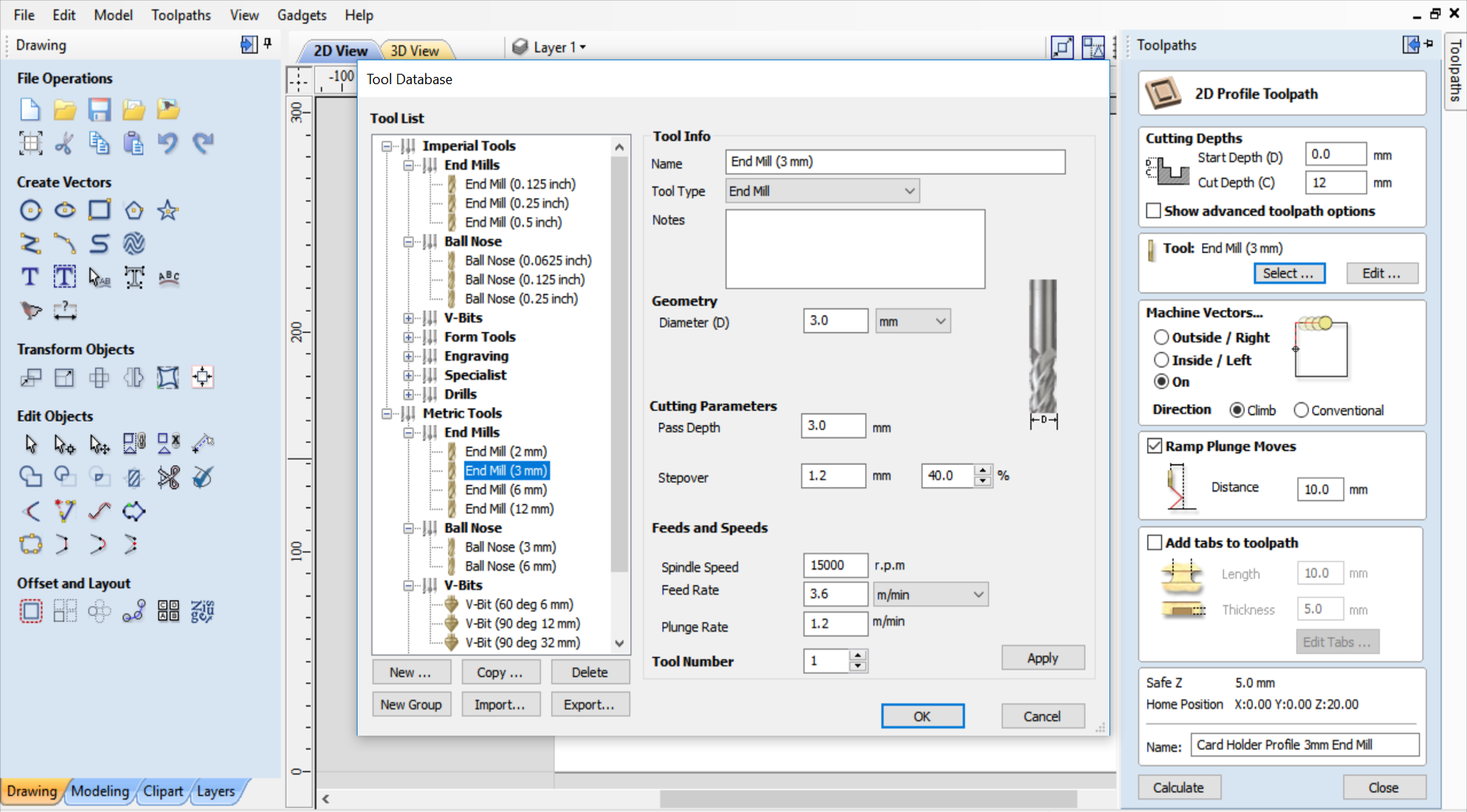

When the Profile Toolpath menu opens, go to Tool and click on Select to choose your cutter and settings.

In the Tool List, go to Metric Tools and select the 3mm End Mill, then enter the following settings:

In Cutting Parameters

Pass Depth = 3mm (Determines how deep the tool will cut with each pass)

Stepover = 40% (Use 40% as default setting. The stepover is the distance between toolpath centre lines, mostly used for pocket toolpaths and 3D milling)

In Feeds and Speeds

Spindle Speed = 15000 rpm (Spindle speed is the constant speed with which a cutter spins on its axis in the tool holder. It is calculated in revolutions per minute)

Feed Rate = 3.6m/min (Feed rate is the speed at which a cutter moves forward on the horizontal plane. Feed rates can be set in a variety of units of measurement, make sure that yours is set to m/min)

Plunge Rate = 1.2m/min (Plunge rate is the speed at which a cutter travels up and down on the vertical plane. It uses the same unit of measurement as the feed rate)

Once you’ve entered these settings, select Apply and OK to return to your Profile Toolpath settings.

The Cutting Parameters and Speeds and Feeds should always be carefully balanced and calibrated to produce the most efficient cut for your material. Efficient in this case means removing the most amount of material in the least amount of time whilst preserving the longevity of your tools and preventing them from getting blunted.

All the speeds and feeds in this course are set for cutting Necuron foam on a Roland MDX-50. If you wish to cut other materials in future, please refer to advice from a technician for speeds and feeds.

Step 3

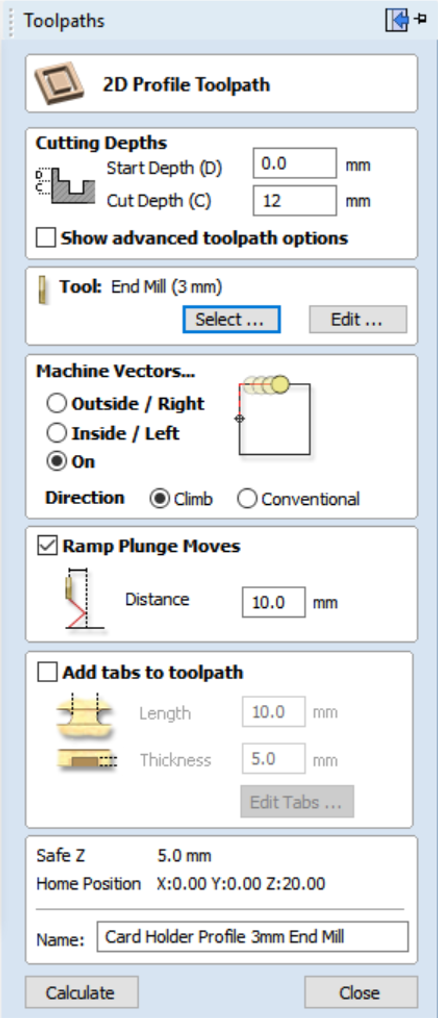

To complete the rest of your Profile Toolpath, enter the following settings:

In Cutting Depths

Start Depth = 0mm (Start Depth is the starting point of your toolpath and should always be at the top surface of your material)

Cut Depth = 12mm (Cut Depth determines how deep you want your toolpath to cut. In this case, our material is 25mm deep and we only want to cut part of the way for our recess)

In Machine Vectors

Select On the Line (The cutter will follow the vector lines using its central axis as the point of reference)

Leave the Direction on Climb as default (Climb and Conventional determine whether the cutter follows toolpaths in a clockwise or anti-clockwise direction. This can be useful when working with wood to direct your cutter to work in the direction of the grain of the wood)

Select Ramp Plunge and set the distance to 10mm. (This setting means that rather than cutting straight down to the full cut depth, the cutter will ramp its entry incrementally into the material over a 10mm length until it has reached the cutting depth then start cutting forward. It is good practise to use a ramp plunge and will increase the longevity of your tools).

Finally name your toolpath. As you will create multiple toolpaths in the same file, it is important to adopt good naming conventions. We suggest you use the following naming convention: Description/Purpose + Toolpath Type + Cutter Size and Type. Your toolpath will be called “Card Holder Profile 3mm End Mill”. To differentiate your toolpaths from the other workshops participants’ toolpaths, also add your initials at the start of the name.

Once you’ve named it, press Calculate to complete your settings.