Course navigation

-

Unit 1 - Create a 2D Design

Unit 2 - Set up Toolpaths from a 2D Design

Unit 3 - Have a go at CNC Milling

1—Customise your design

2—Calibrate the materials settings

3—Output your cutting data

4—Checkpoint!

Unit 4 - Create a 3D file for CNC Milling

Unit 5 - Import your Files for 3D Milling

Unit 6 - Set up Toolpaths for 3D Milling

Customise your design

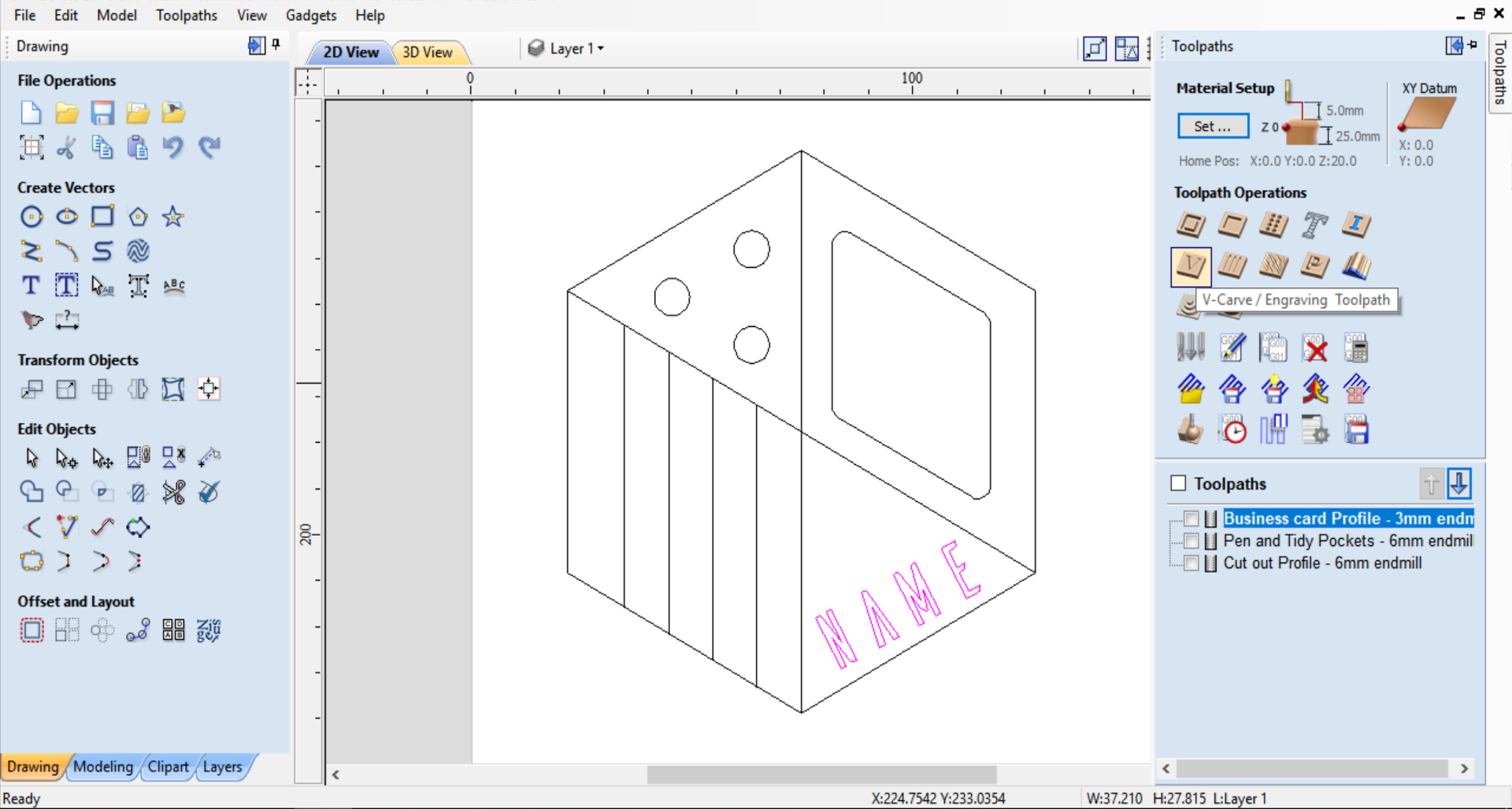

In this lesson, you will learn to customise a template desk tidy design with an engrave toolpath.

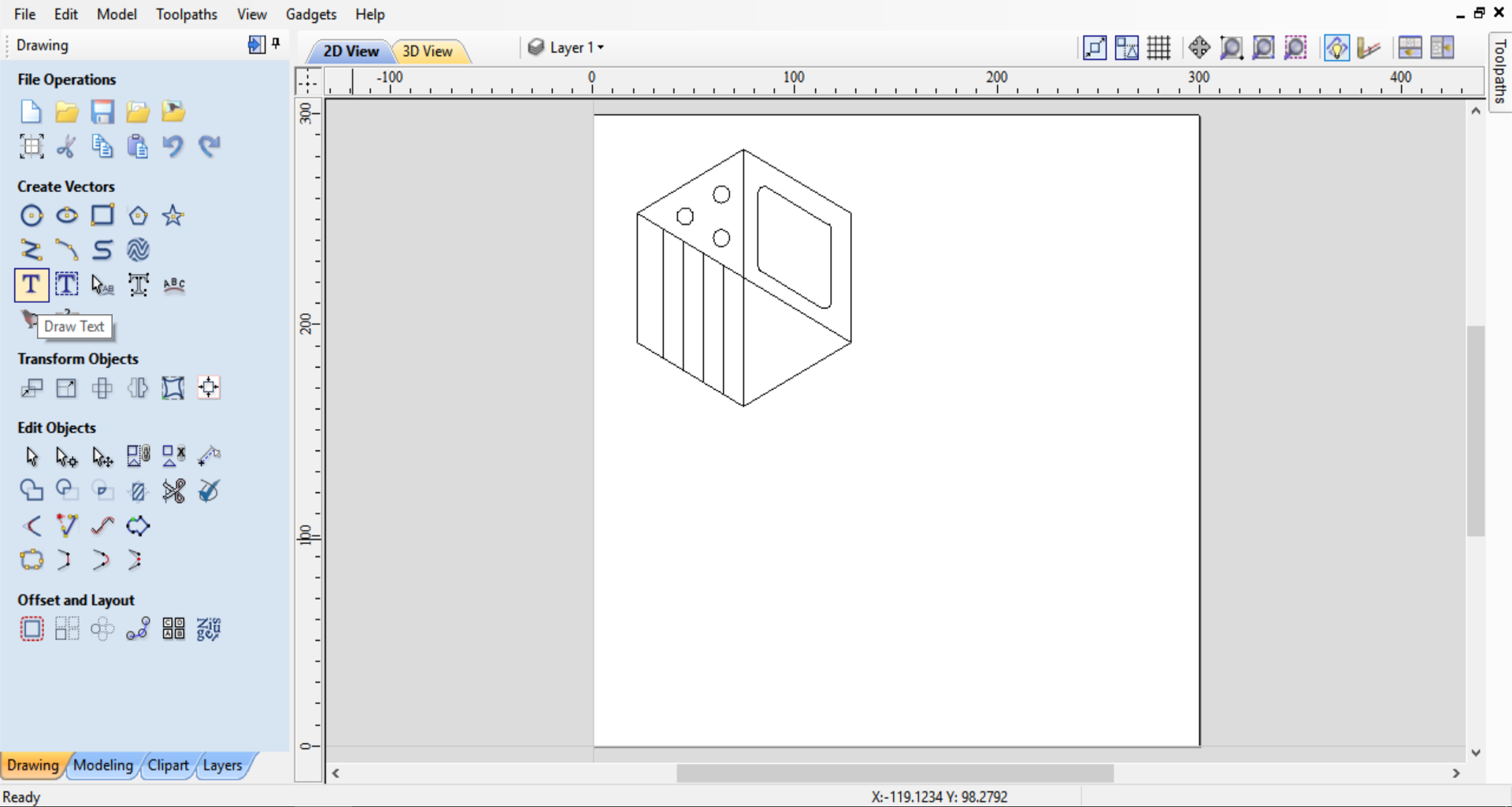

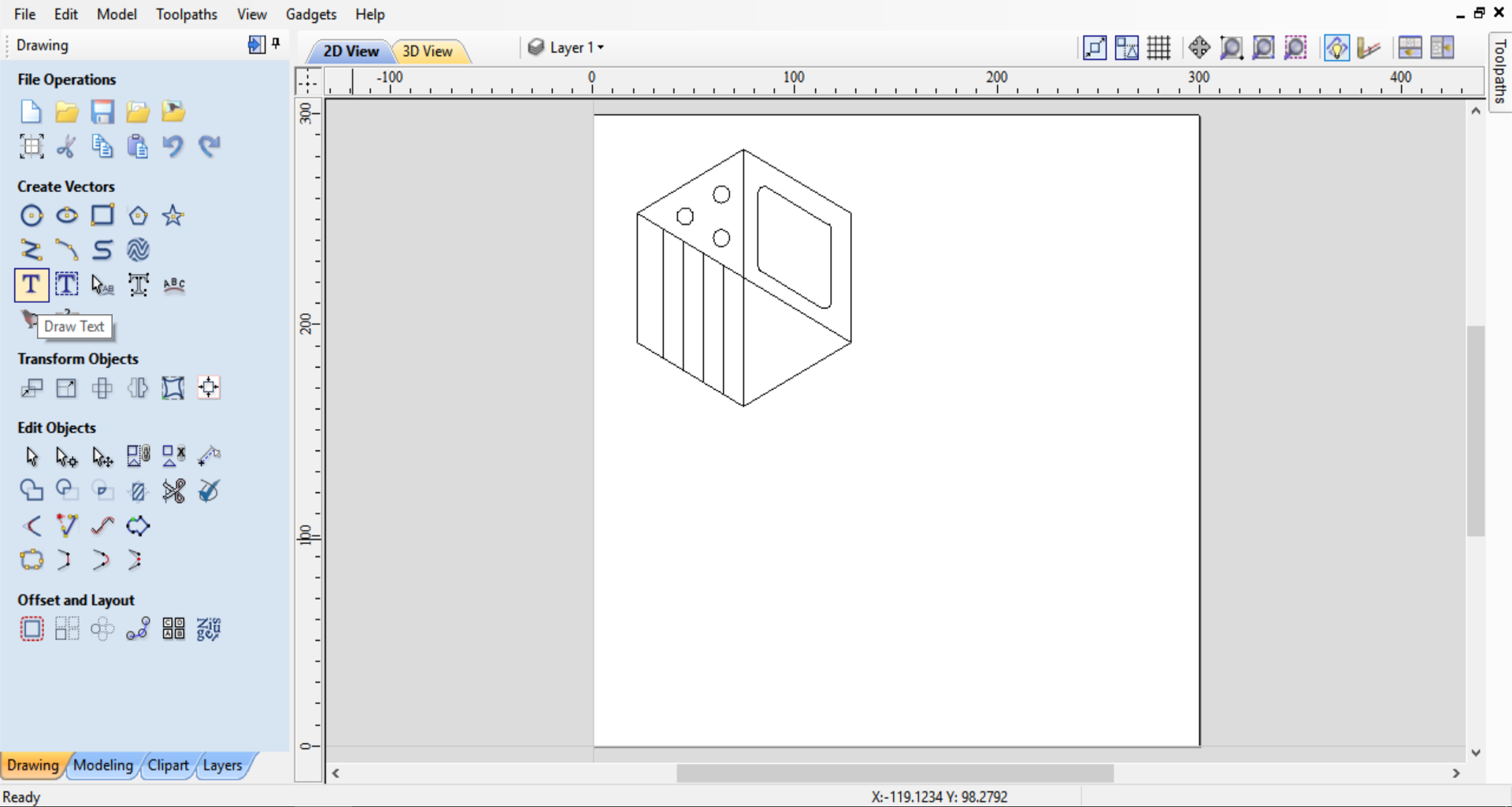

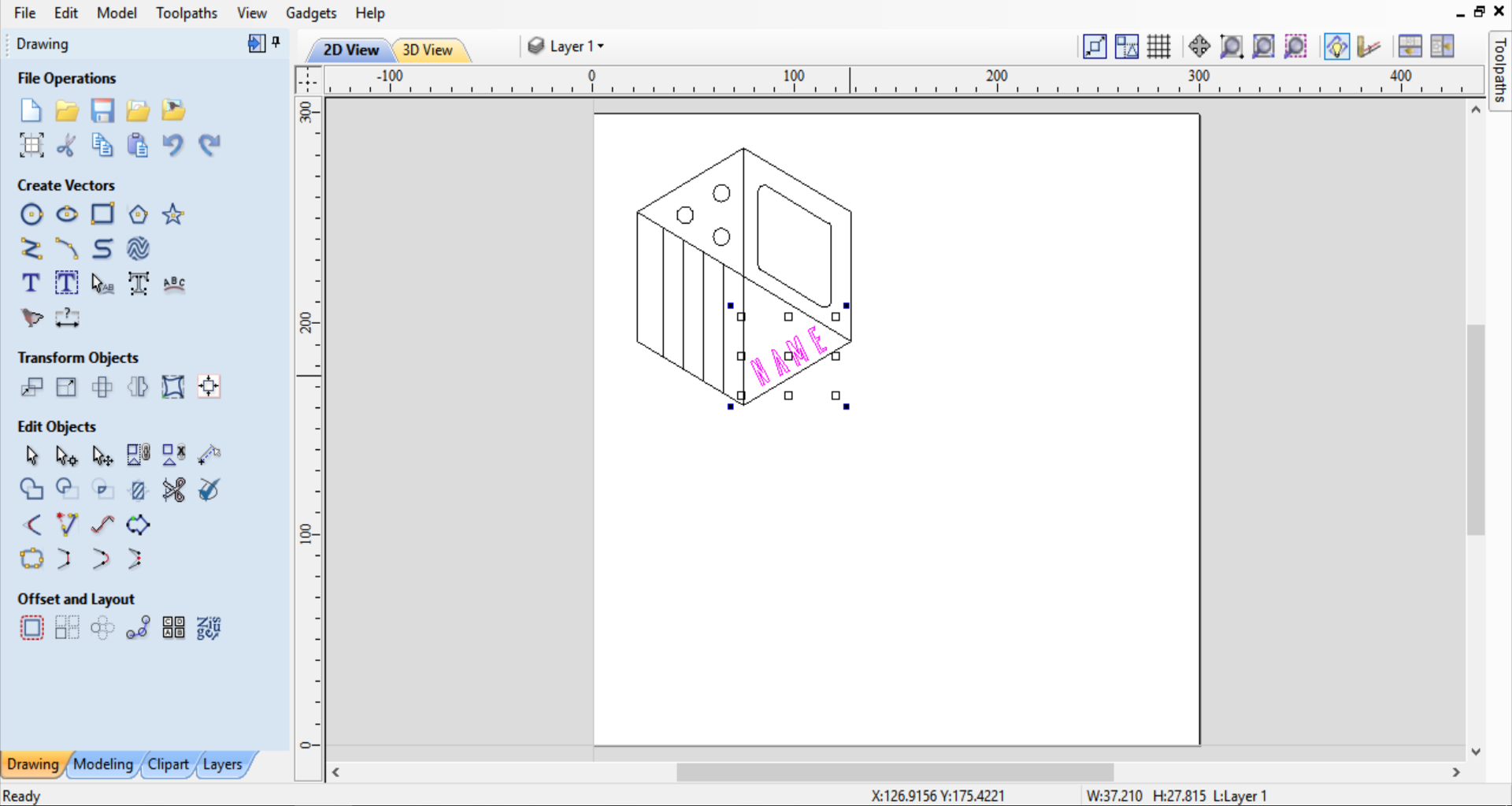

Have a go at personalising it with your name. Select the Draw Text tool in Create Vectors.

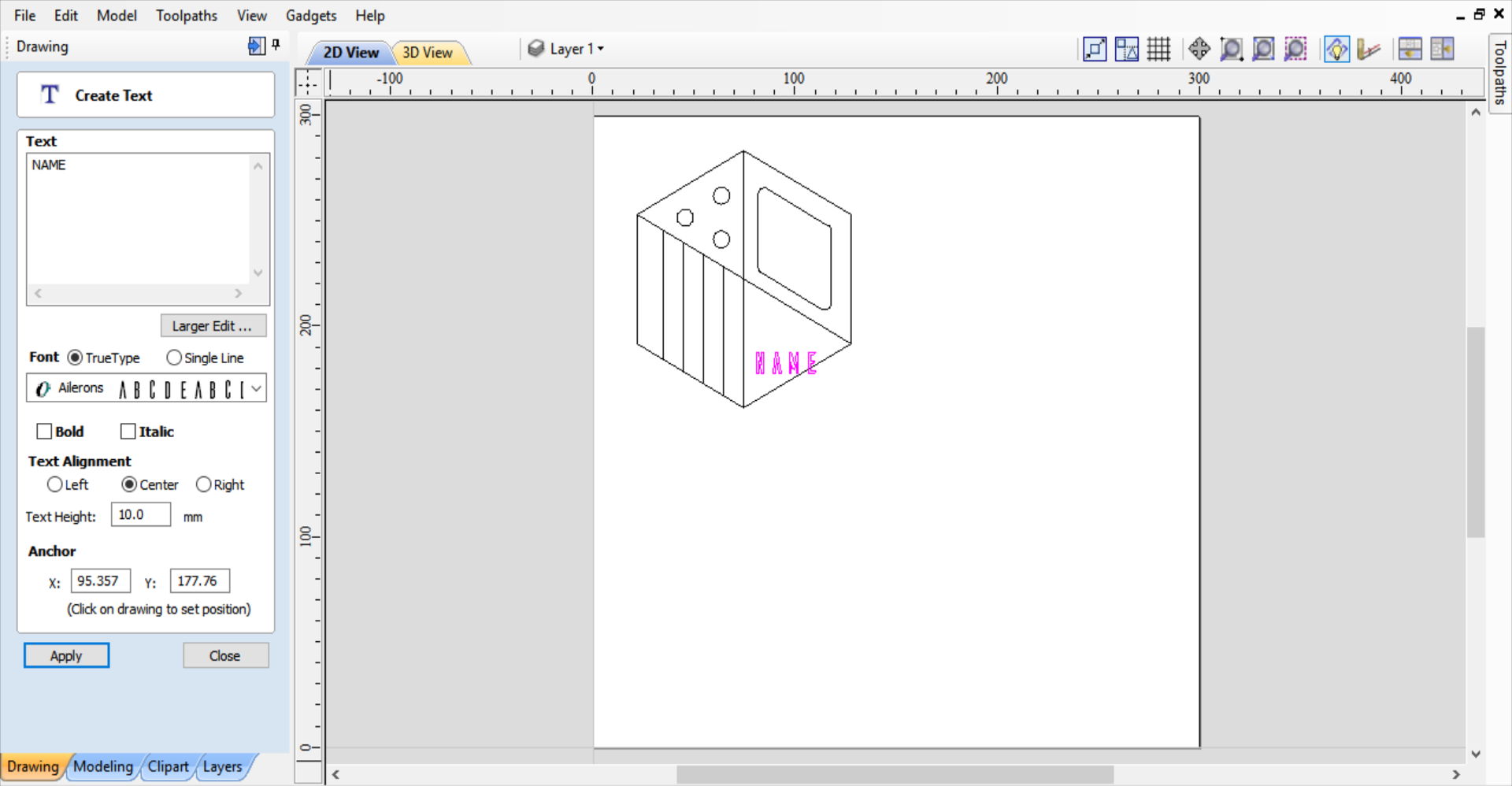

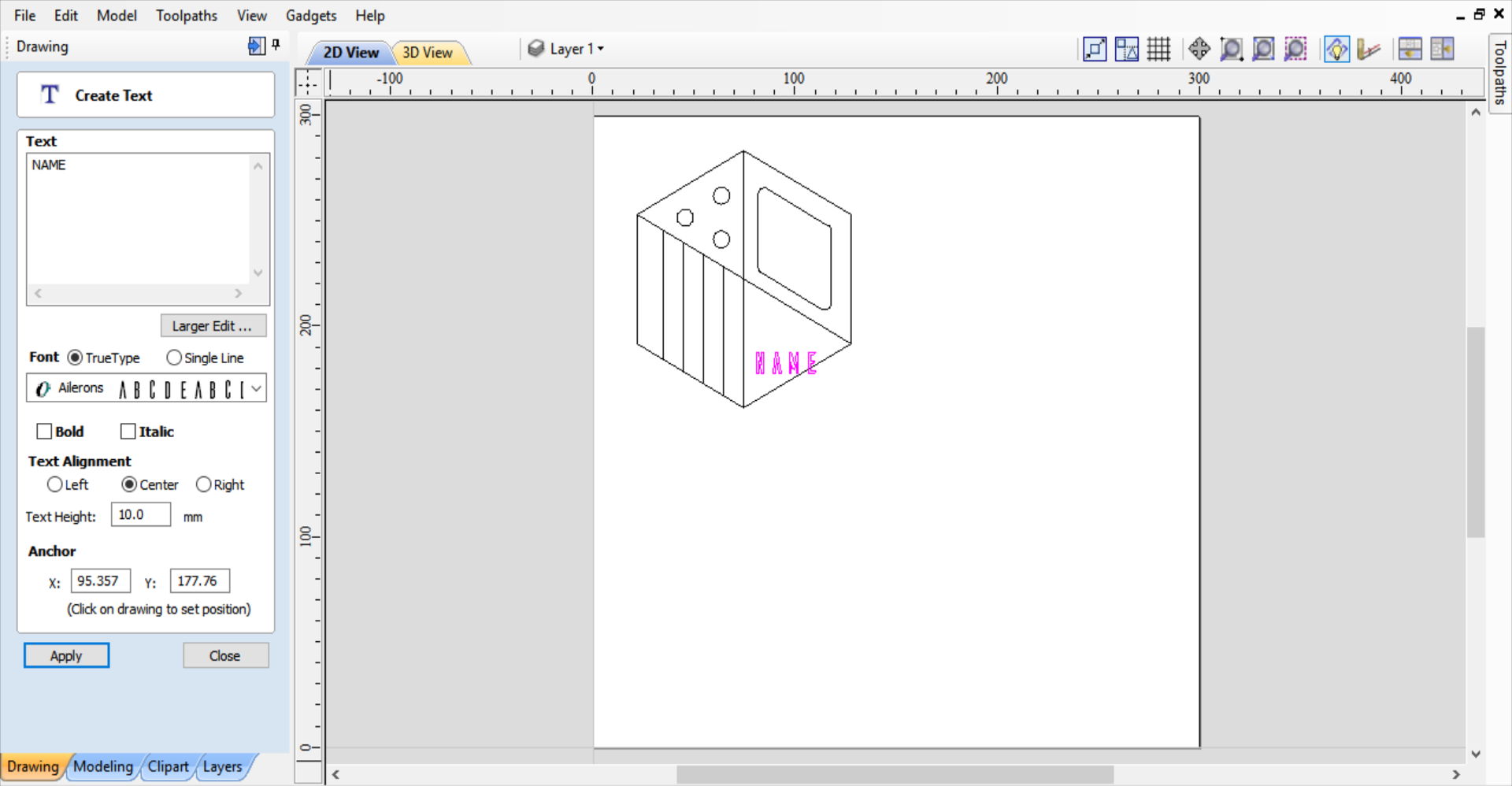

In the Create Text dialogue box, type in your name, select a font and set an appropriate size, then click on the document to place your text.

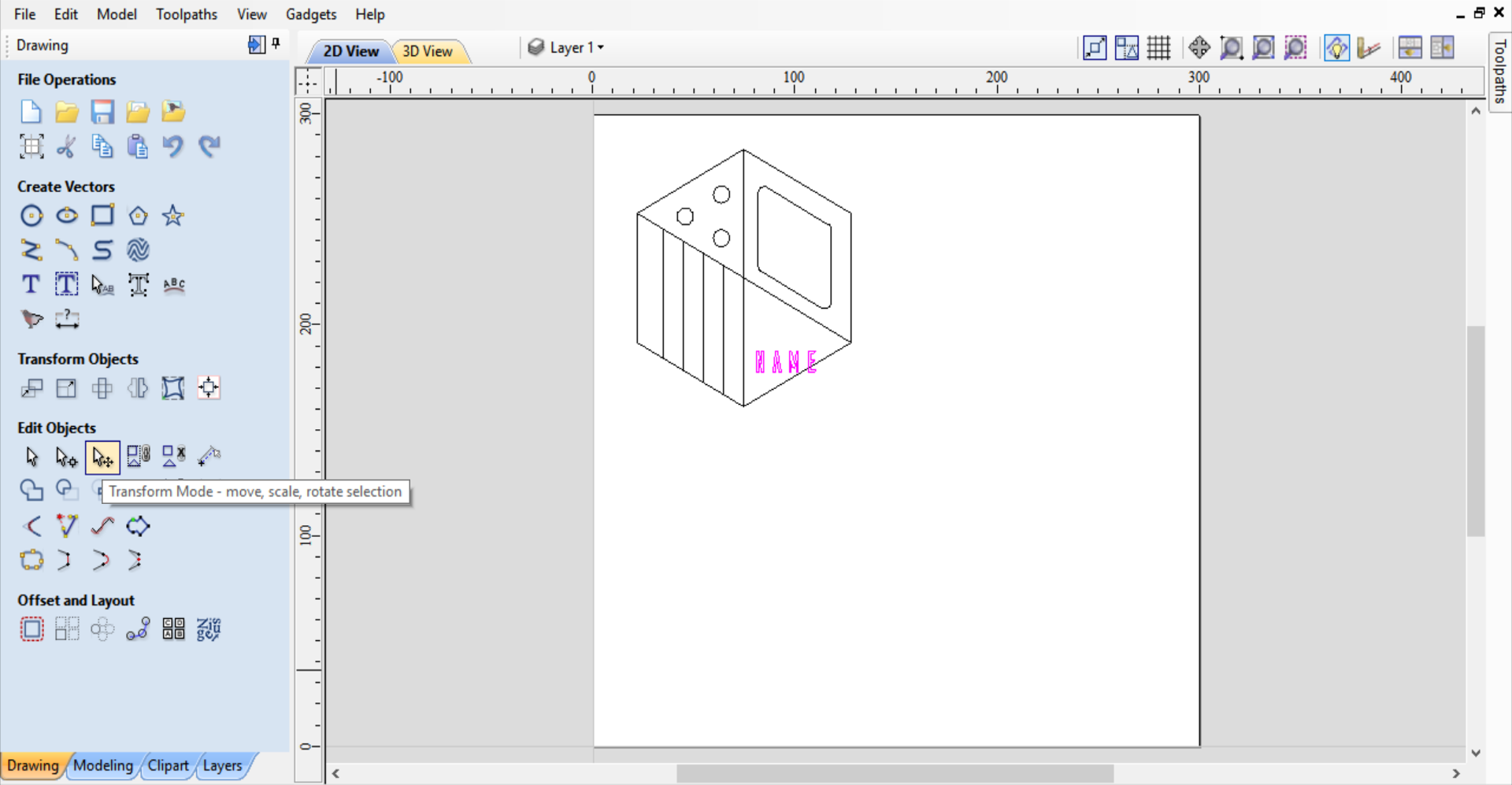

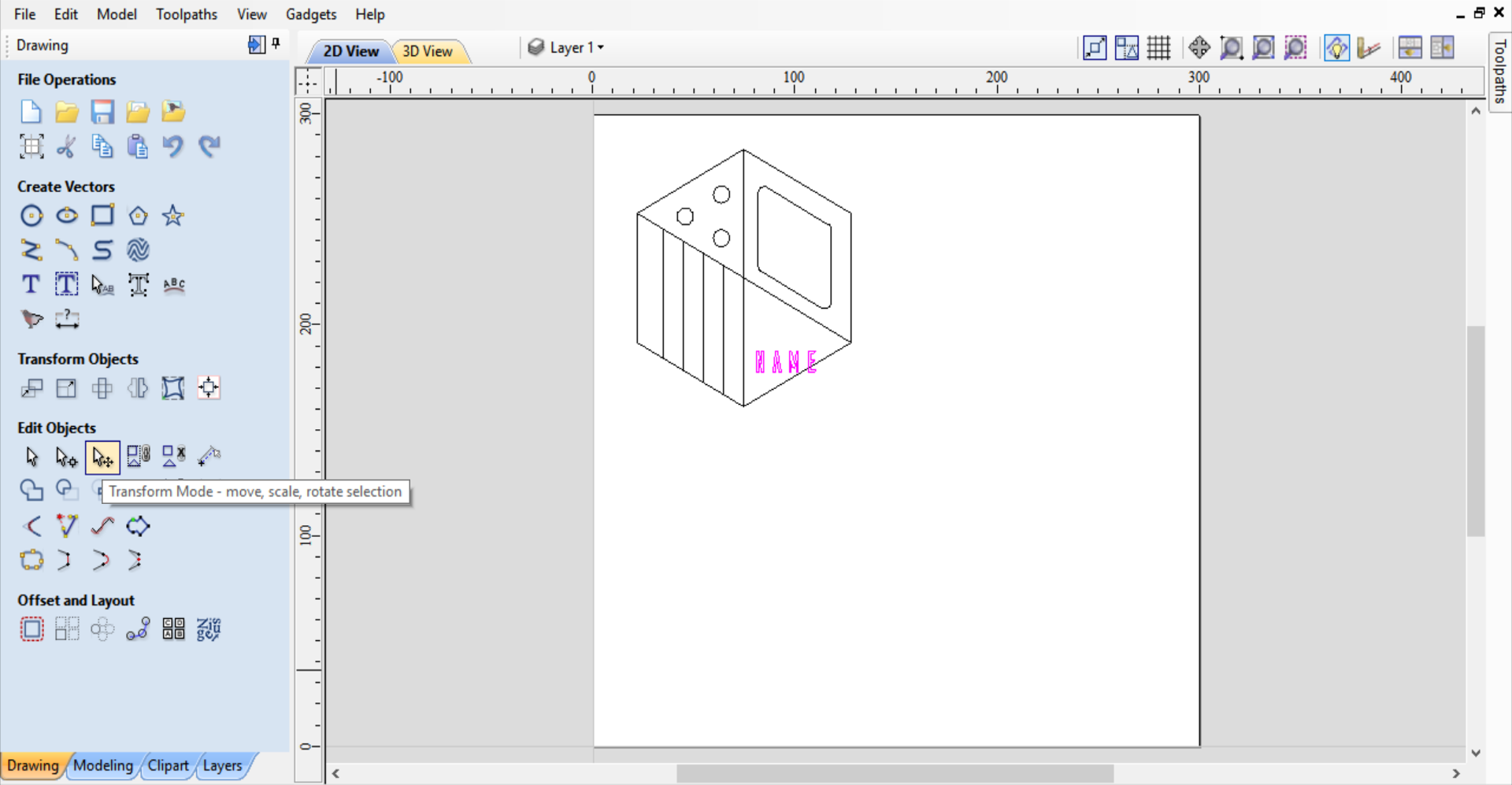

Close the Create Text dialogue box then select the Transform selection tool.

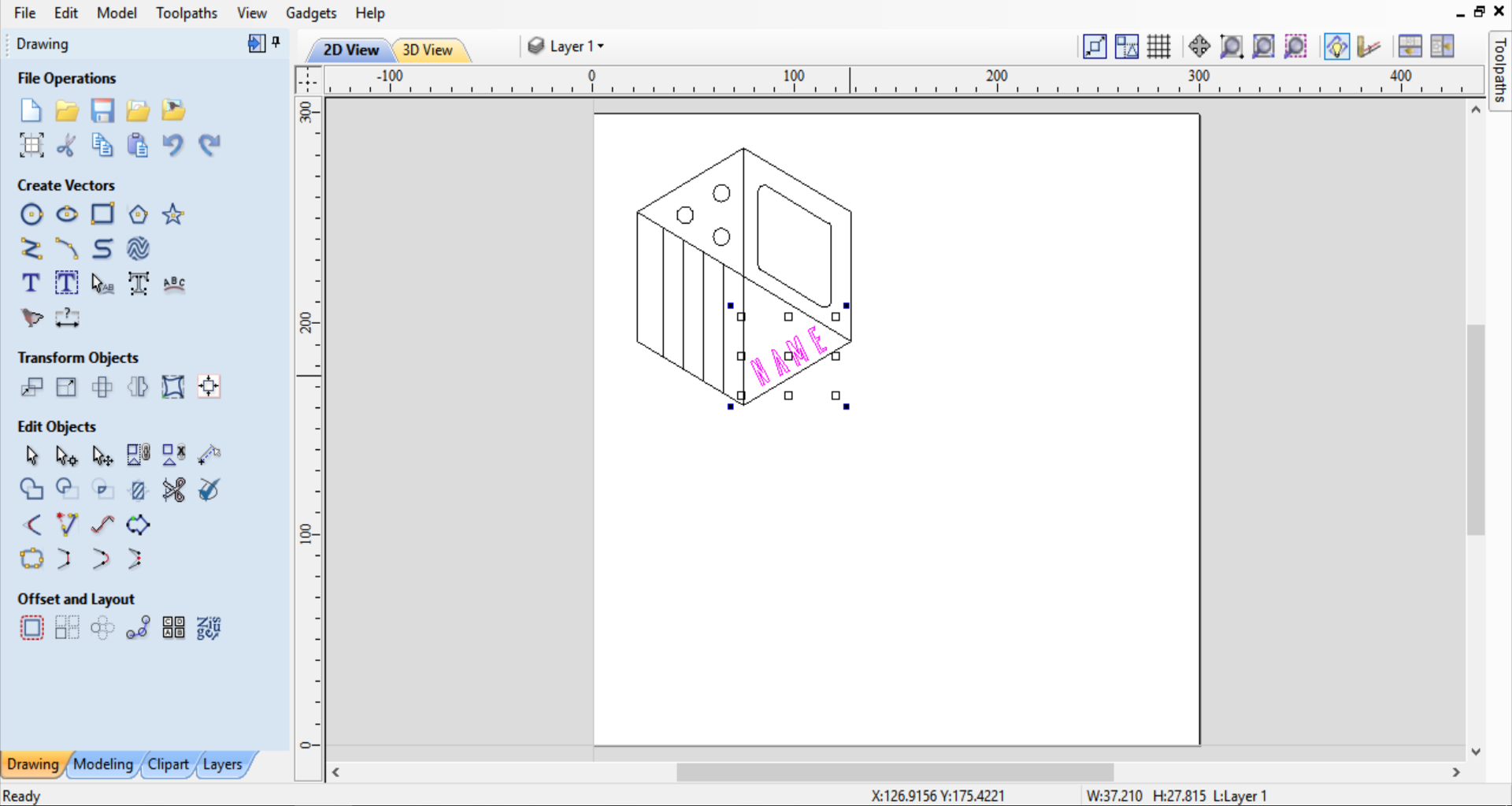

Use the Transform tool to move, rotate and resize your text until you are satisfied with its position in the design.

You are now ready to start creating your engraving toolpath.

When the Engraving Toolpath menu opens, go to Tool and Select to choose your cutter and settings.

In the Tool List, go to Metric Tools and select the V-Bit (60 deg 6mm), then enter the following settings:

In Cutting Parameters

In Feeds and Speeds

Once you’ve entered these settings, select Apply and OK to return to your Engraving Toolpath settings.

In Cutting Depths

Start Depth = 0mm

Leave Flat Depth unselected (The depth of an engraving toolpath is determined by how deep the tool will cut before the cutting edges of the tool meet the full width of the vector lines. As long as the tool width is larger than the vector width, a flat depth isn’t required. In the event that the width of the tool is smaller than the width of the vector, a flat depth can be set to set how deep the tool should cut)

Having set your tool settings and cutting depth, you can now name your toolpath using the same naming conventions as in previous units. Your toolpath will be called “Name Engrave 60 deg 6mm V-Bit”. Remember to add your initials at the start of the name to differentiate your toolpaths from the other workshops participants’ toolpaths.

Once you’ve named it, press Calculate to complete your settings.

If you got to the Toolpaths Tab, you will find a list of the toolpaths set for this file. It is good practice to set up your toolpaths in the order in which you want them to cut. It is also helpful to group toolpaths using the same tool whenever possible. Your engraving toolpath should therefore be moved to second position in the toolpath order, before the 6mm pocket and cut out toolpaths. Select the toolpath to highlight it then use the up and down arrows to move it in the order position of your choice.

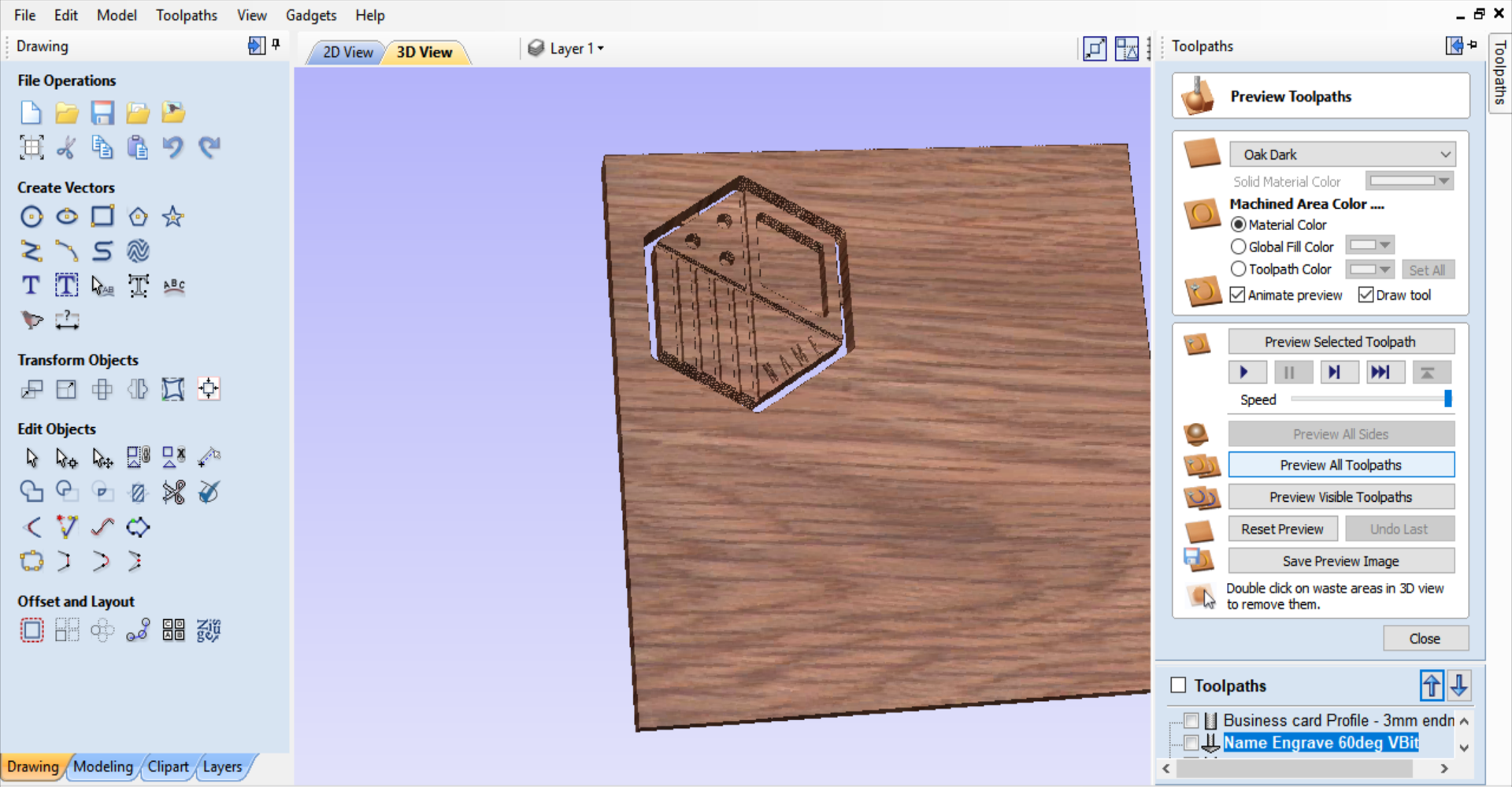

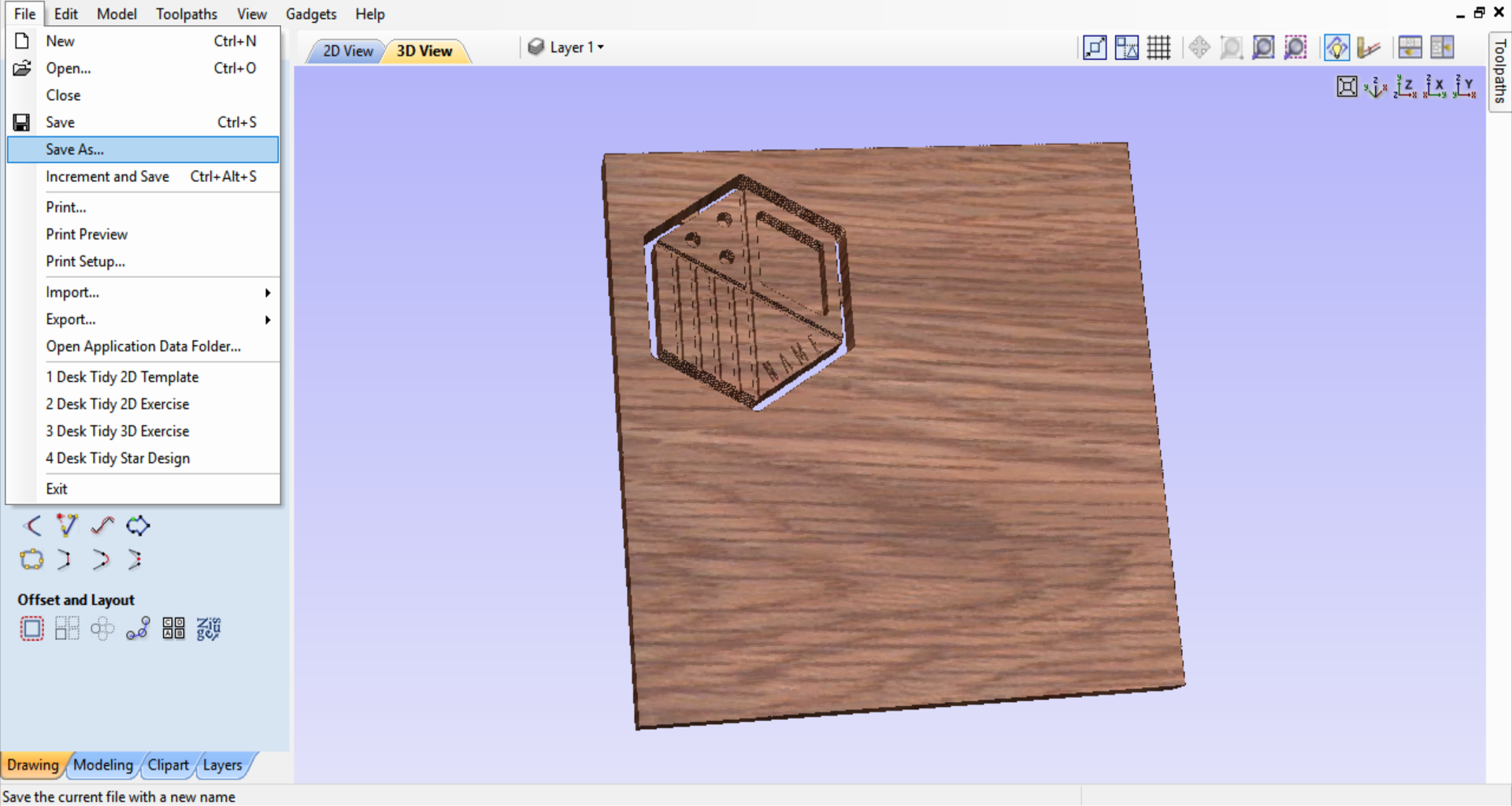

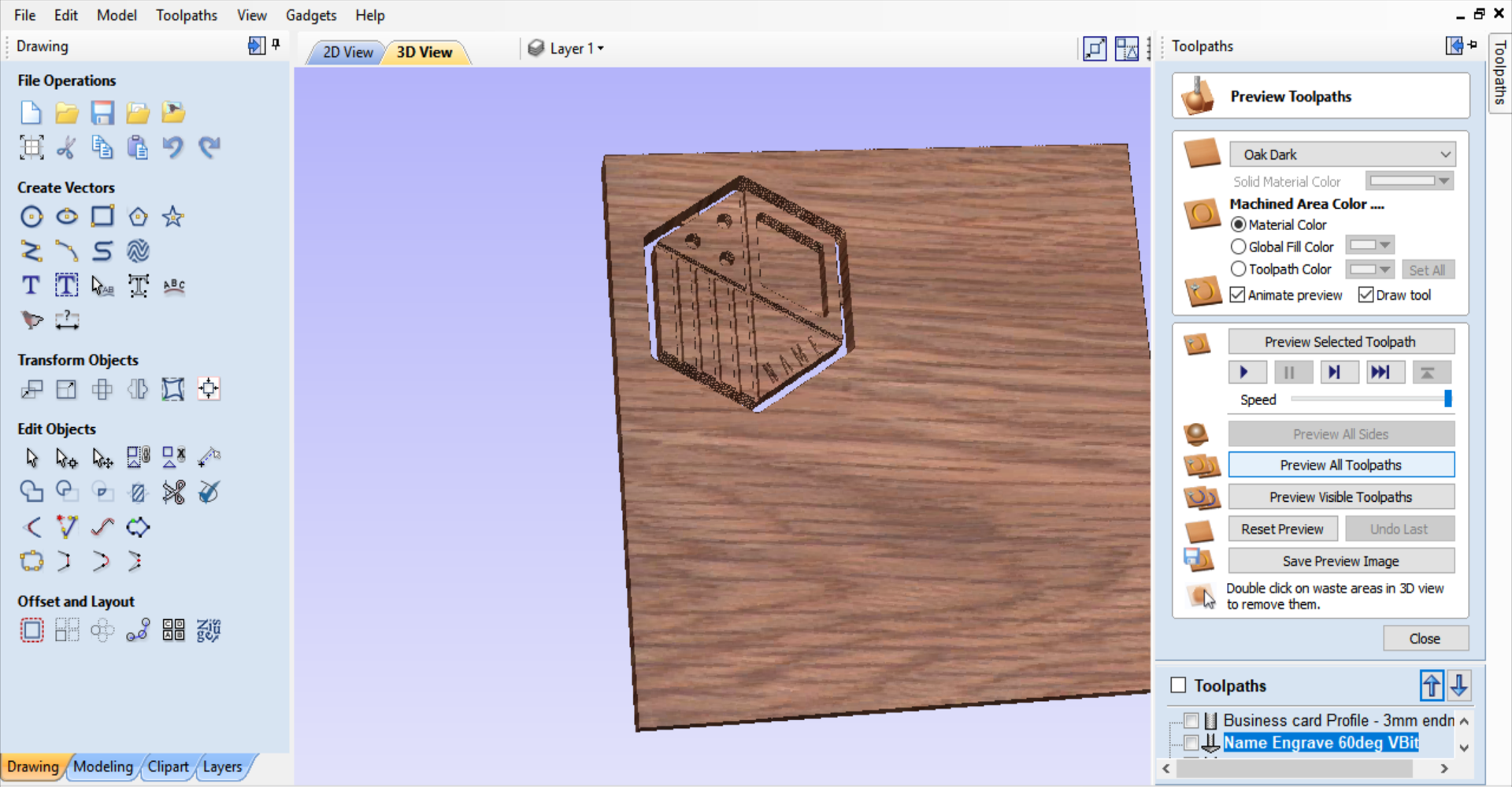

Select Preview all Toolpaths. You should now have a preview of your toolpaths as they will cut in the material. Check that all the toolpaths look the way you expect them to.

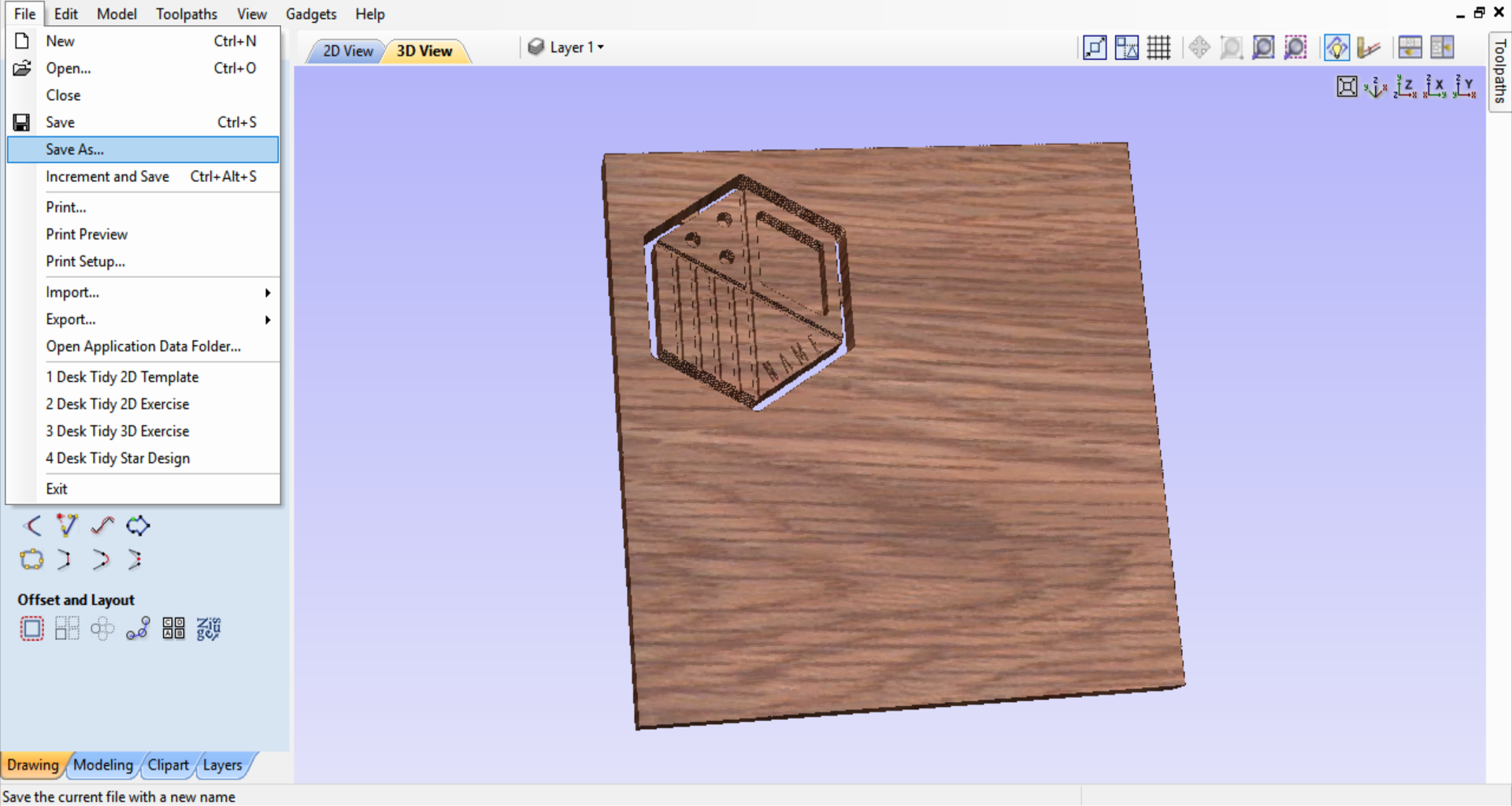

If you’re satisfied with your toolpaths, it is now time to save your design and toolpaths in a VCarve project file, ready to output to the CNC Mill. First go to File and Save As.

Save your file on the desktop with a memorable name.

Step 1

Find the Desk Tidy 2D Template .crv file on the desktop and open it in VCarve Pro. You will find a 2D milling design set up with toolpaths ready to cut on the Roland MDX-50.Have a go at personalising it with your name. Select the Draw Text tool in Create Vectors.

In the Create Text dialogue box, type in your name, select a font and set an appropriate size, then click on the document to place your text.

Close the Create Text dialogue box then select the Transform selection tool.

Use the Transform tool to move, rotate and resize your text until you are satisfied with its position in the design.

You are now ready to start creating your engraving toolpath.

Step 2

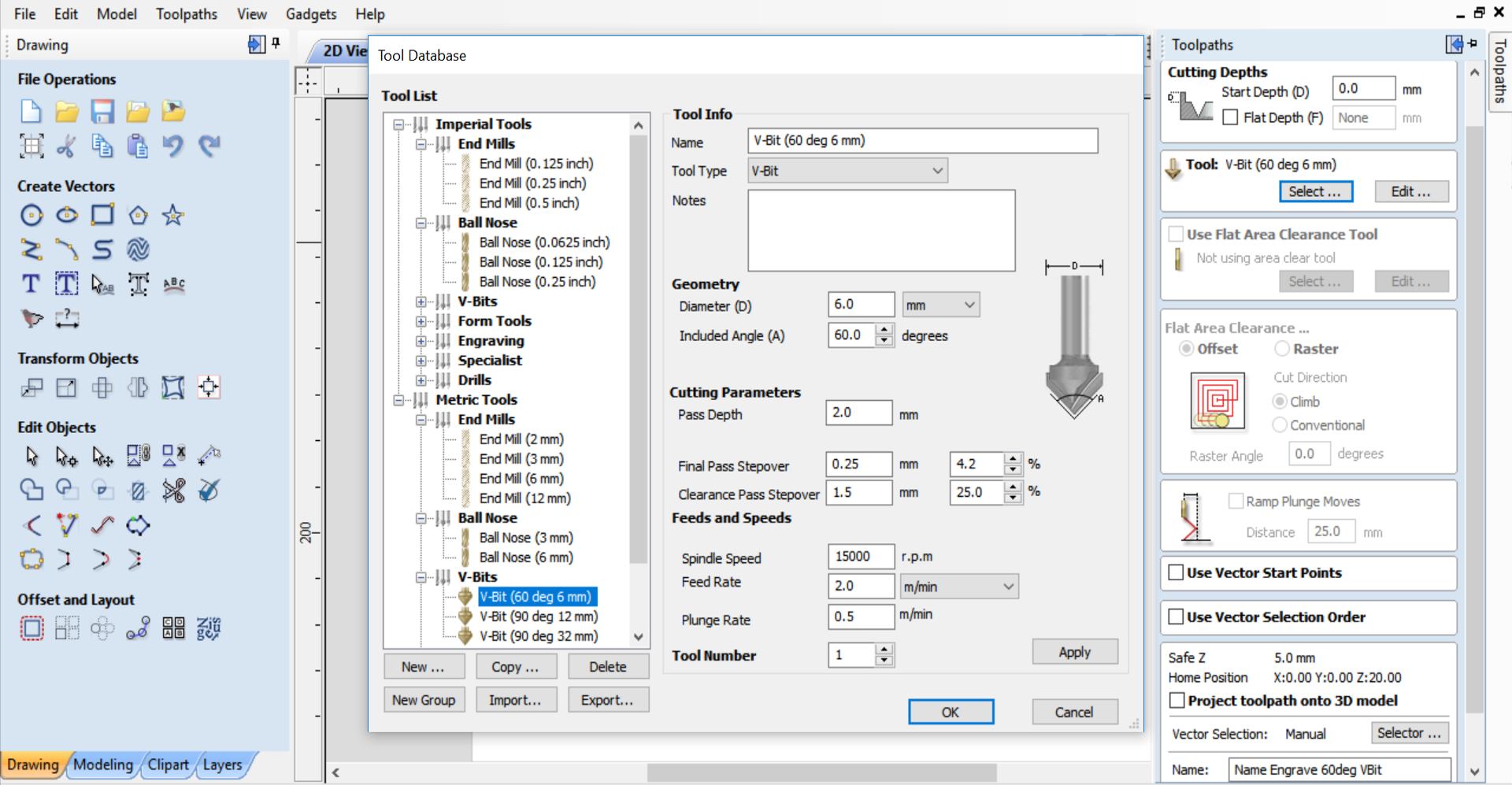

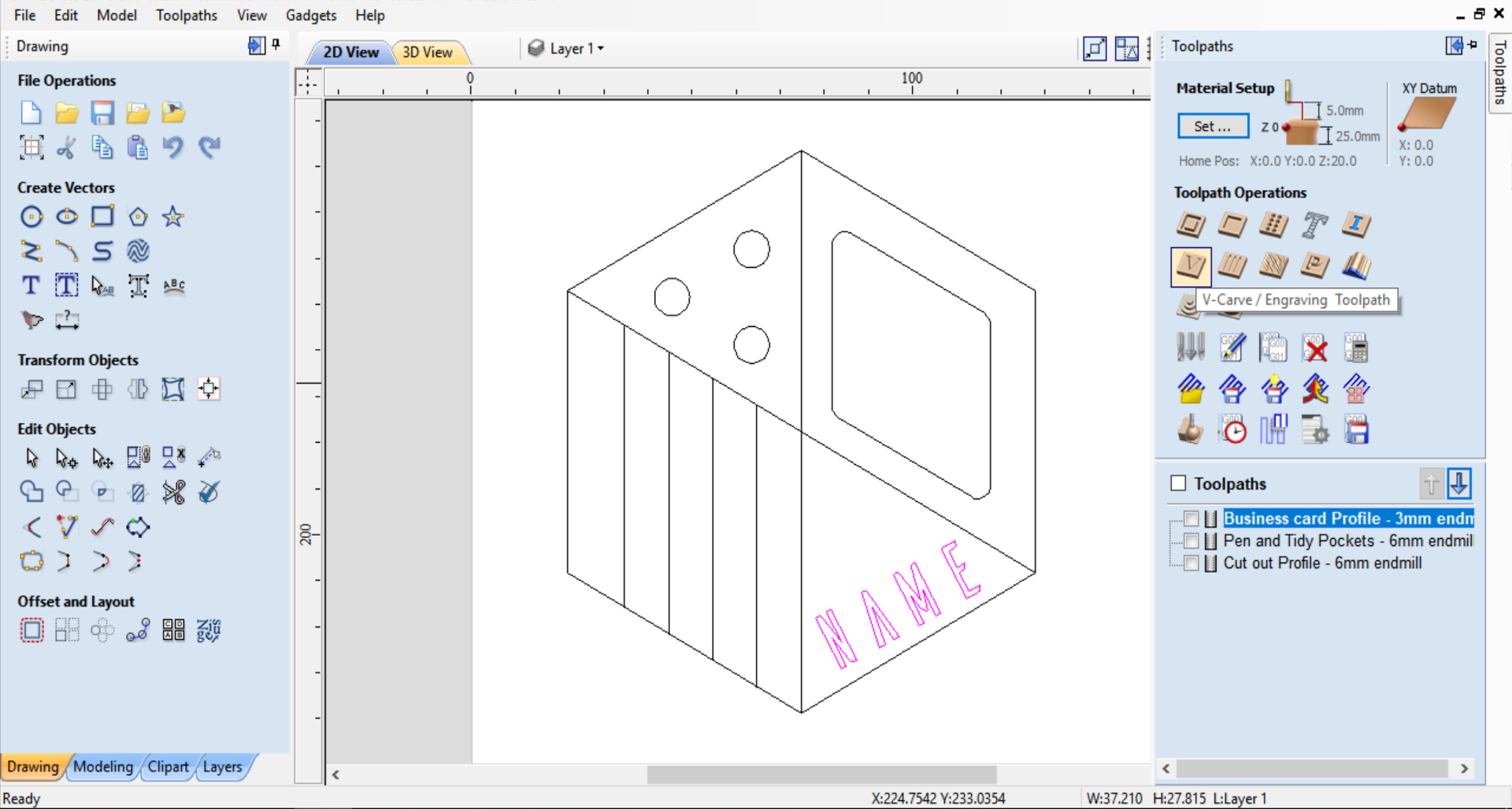

Use the standard Selection Mode tool in Edit Objects to select the vector you’ve created then go to Toolpaths and select a VCarve/Engraving Toolpath in Toolpath Operations.

When the Engraving Toolpath menu opens, go to Tool and Select to choose your cutter and settings.

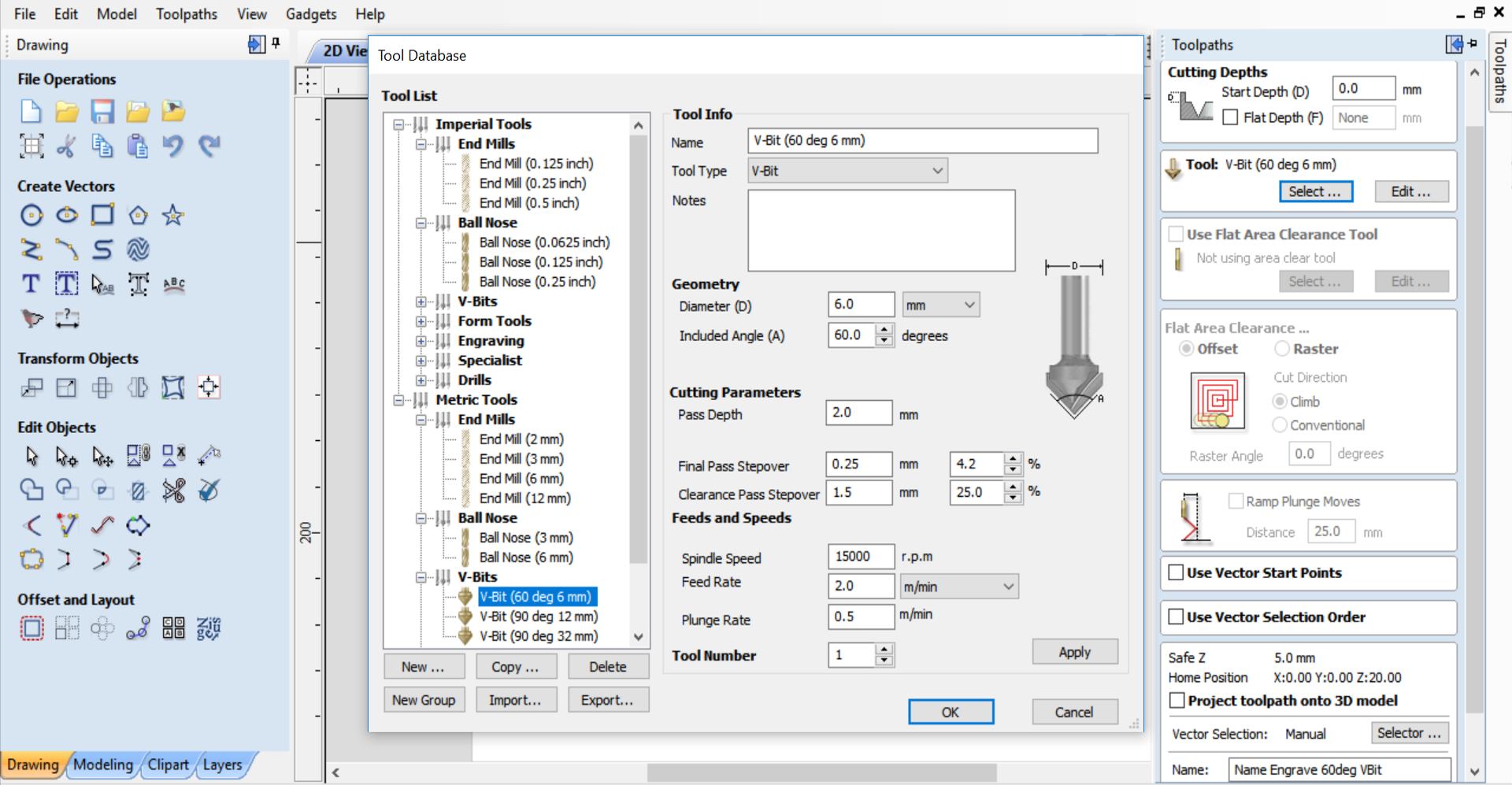

In the Tool List, go to Metric Tools and select the V-Bit (60 deg 6mm), then enter the following settings:

In Cutting Parameters

- Pass Depth = 2mm

- Final Pass Stepover = 4.2%

- Clearance Pass Stepover = 25%

In Feeds and Speeds

- Spindle Speed = 15000 rpm

- Feed Rate = 2m/min

- Plunge Rate = 0.5m/min

Once you’ve entered these settings, select Apply and OK to return to your Engraving Toolpath settings.

Step 3

To complete the rest of your Profile Toolpath, enter the following settings:

In Cutting Depths

Start Depth = 0mm

Leave Flat Depth unselected (The depth of an engraving toolpath is determined by how deep the tool will cut before the cutting edges of the tool meet the full width of the vector lines. As long as the tool width is larger than the vector width, a flat depth isn’t required. In the event that the width of the tool is smaller than the width of the vector, a flat depth can be set to set how deep the tool should cut)

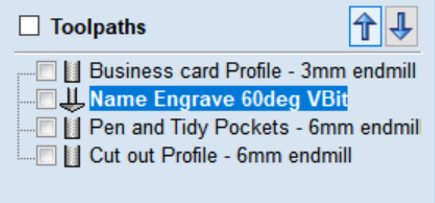

Having set your tool settings and cutting depth, you can now name your toolpath using the same naming conventions as in previous units. Your toolpath will be called “Name Engrave 60 deg 6mm V-Bit”. Remember to add your initials at the start of the name to differentiate your toolpaths from the other workshops participants’ toolpaths.

Once you’ve named it, press Calculate to complete your settings.

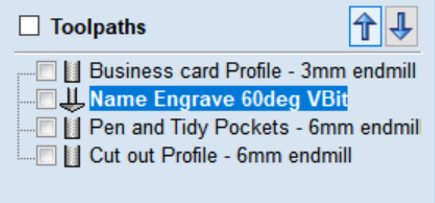

If you got to the Toolpaths Tab, you will find a list of the toolpaths set for this file. It is good practice to set up your toolpaths in the order in which you want them to cut. It is also helpful to group toolpaths using the same tool whenever possible. Your engraving toolpath should therefore be moved to second position in the toolpath order, before the 6mm pocket and cut out toolpaths. Select the toolpath to highlight it then use the up and down arrows to move it in the order position of your choice.

Step 4

To double-check your toolpaths, we recommend that you now preview your toolpaths using Preview Toolpaths, which opens automatically upon completing a toolpath.Select Preview all Toolpaths. You should now have a preview of your toolpaths as they will cut in the material. Check that all the toolpaths look the way you expect them to.

If you’re satisfied with your toolpaths, it is now time to save your design and toolpaths in a VCarve project file, ready to output to the CNC Mill. First go to File and Save As.

Save your file on the desktop with a memorable name.