Course navigation

-

Unit 1 - Create a 2D Design

Unit 2 - Set up Toolpaths from a 2D Design

Unit 3 - Have a go at CNC Milling

Unit 4 - Create a 3D file for CNC Milling

Unit 5 - Import your Files for 3D Milling

Unit 6 - Set up Toolpaths for 3D Milling

1—Set up a roughing toolpath

2—Set up a finishing toolpath

3—Set up a cut-out toolpath

Set up a roughing toolpath

Learn to set your material cutting plane and generate a roughing toolpath.

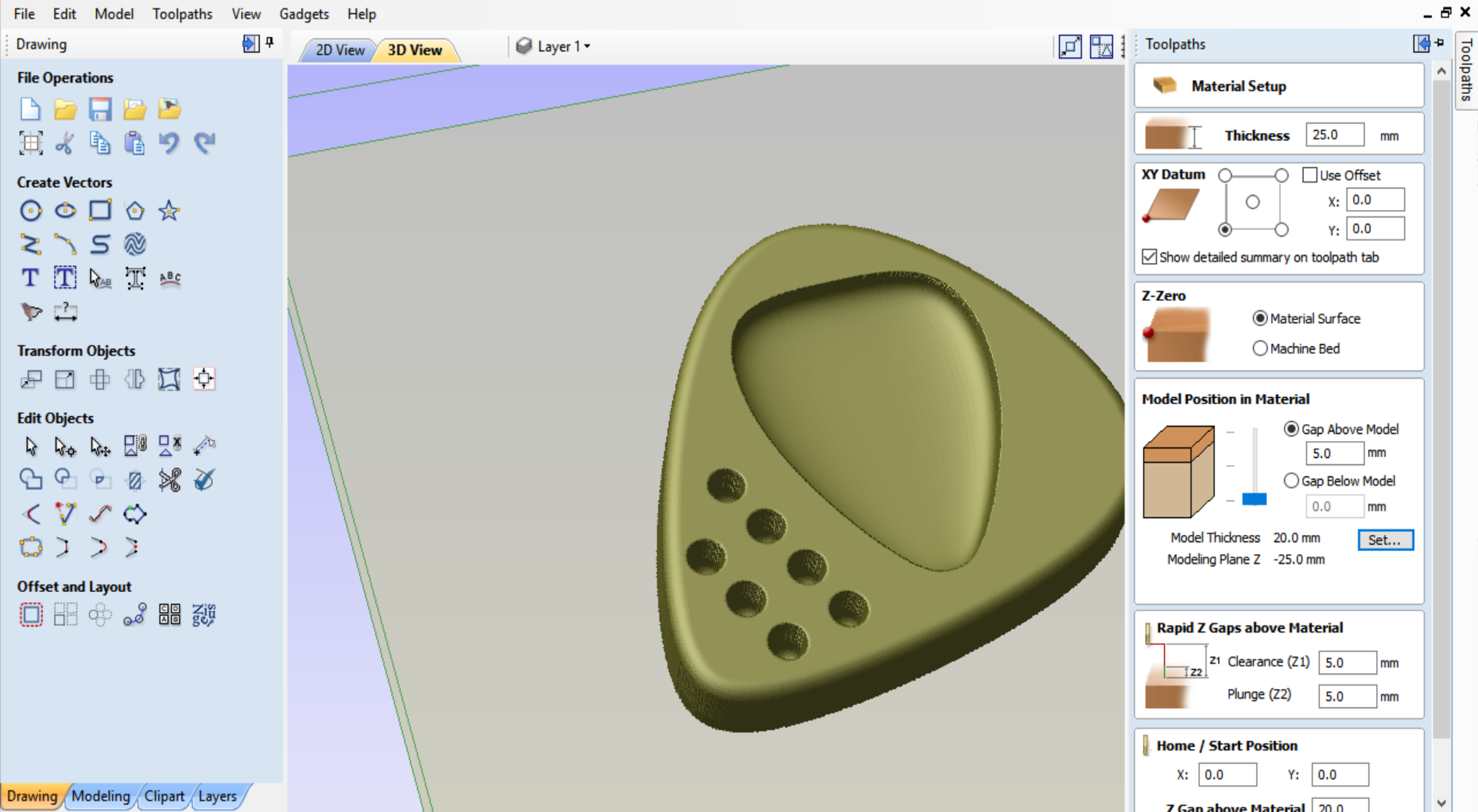

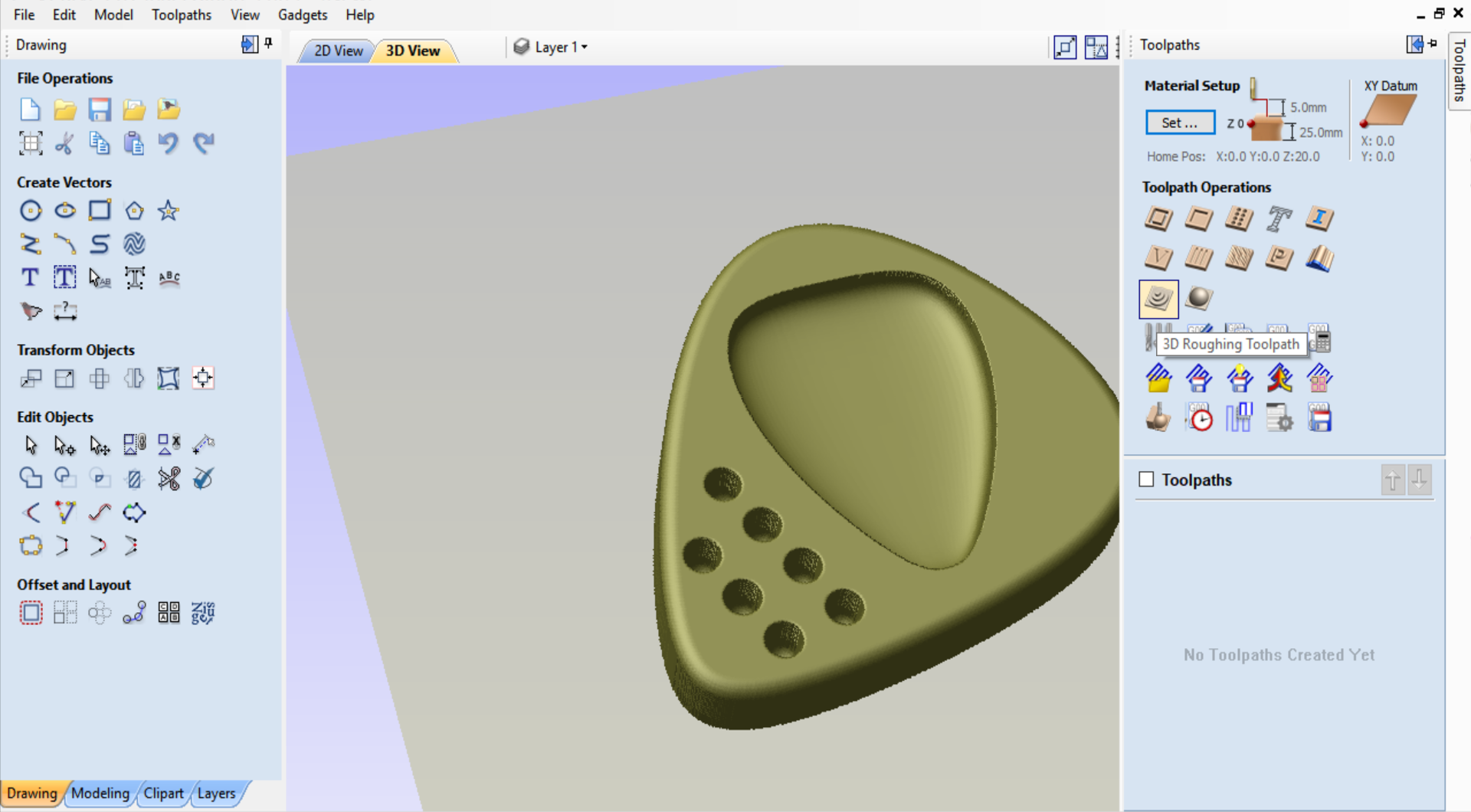

In Material Setup, go to Model Position in Material. Your material is 25mm thick whereas your 3D model is 20mm thick. To make sure that the 5mm difference gets milled off the top of your material, set a Gap Above Model of 5mm.

Select OK to save those settings.

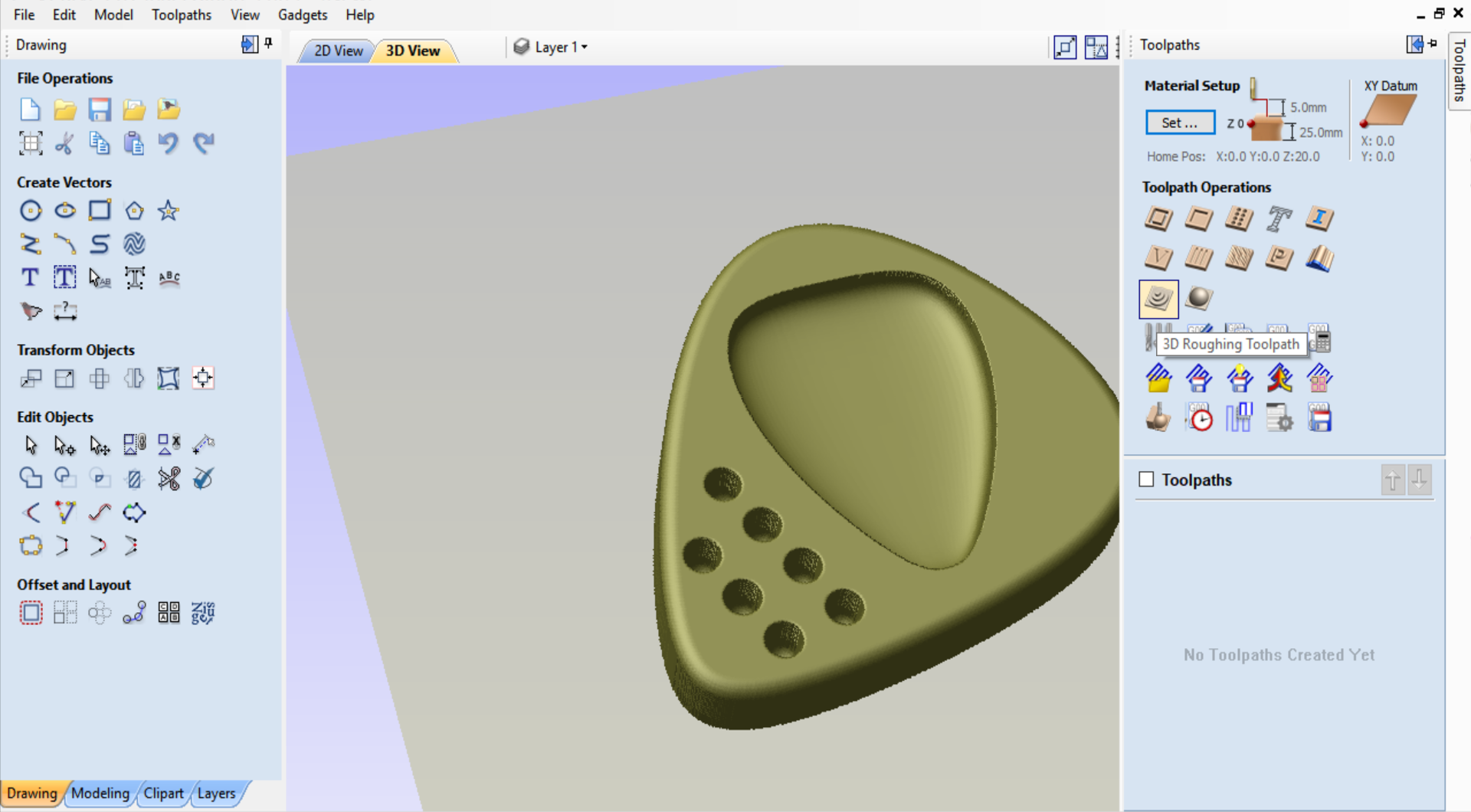

Go to the Toolpaths tab and select a 3D Roughing toolpath.

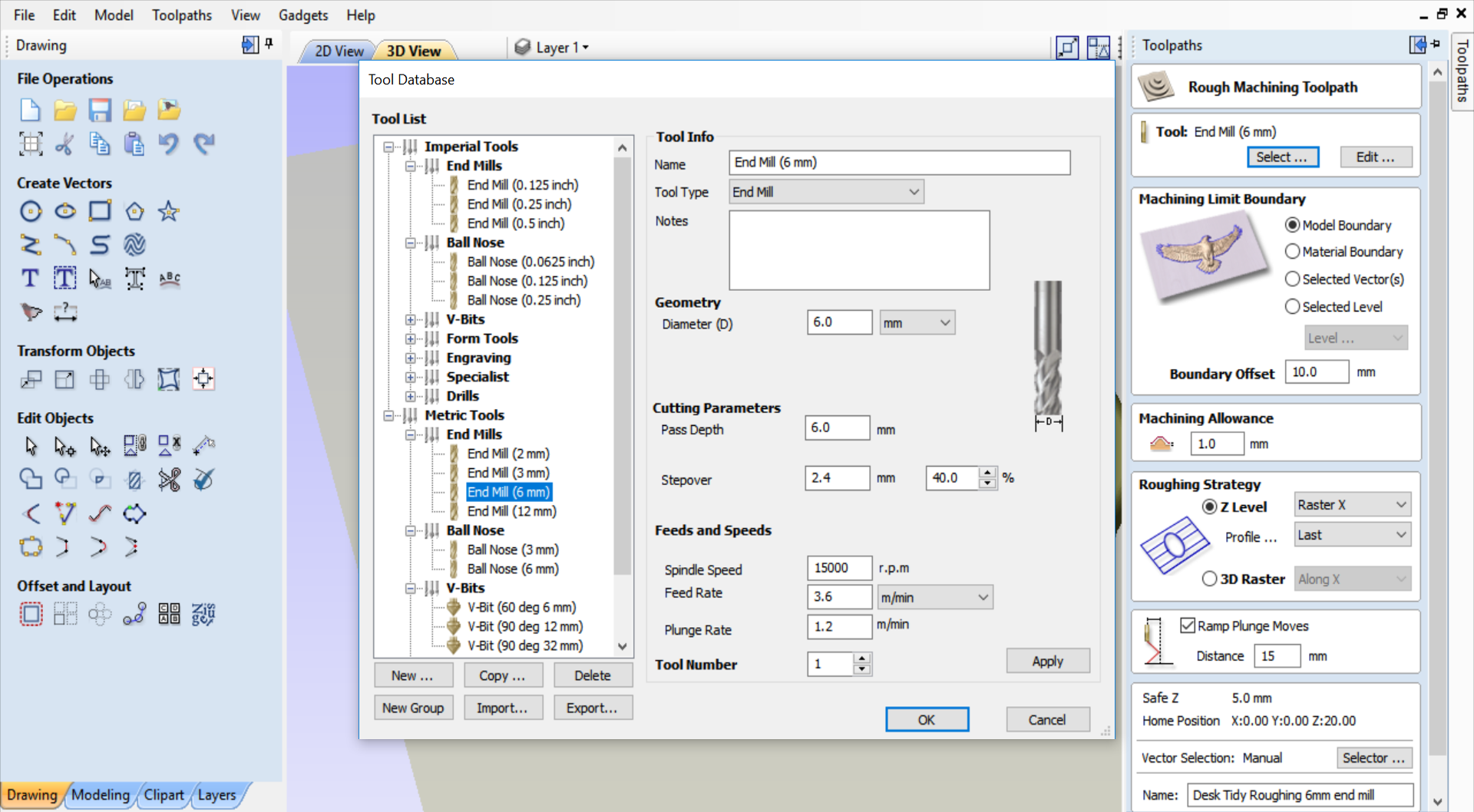

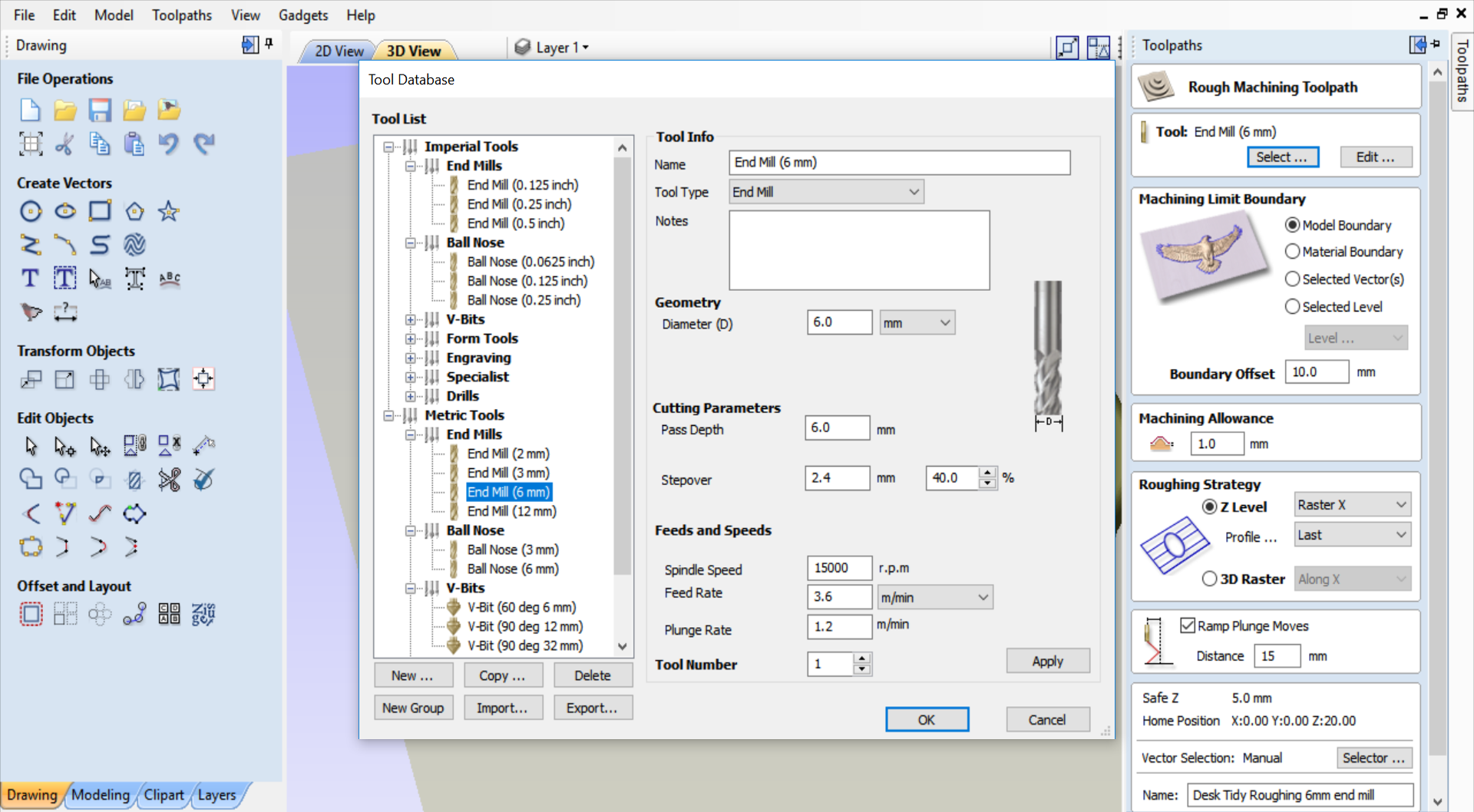

When the Rough Machining Toolpath menu opens, go to Tool and Select to choose your cutter and settings.

In the Tool List, go to Metric Tools and select the 6mm End Mill, then enter the following settings:

In Cutting Parameters

In Feeds and Speeds

Once you’ve entered these settings, select Apply and OK to return to your Rough Machining Toolpath settings.

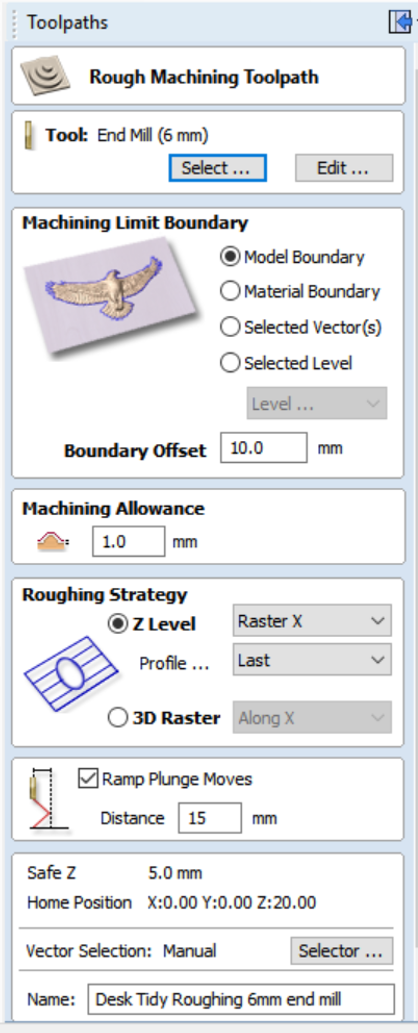

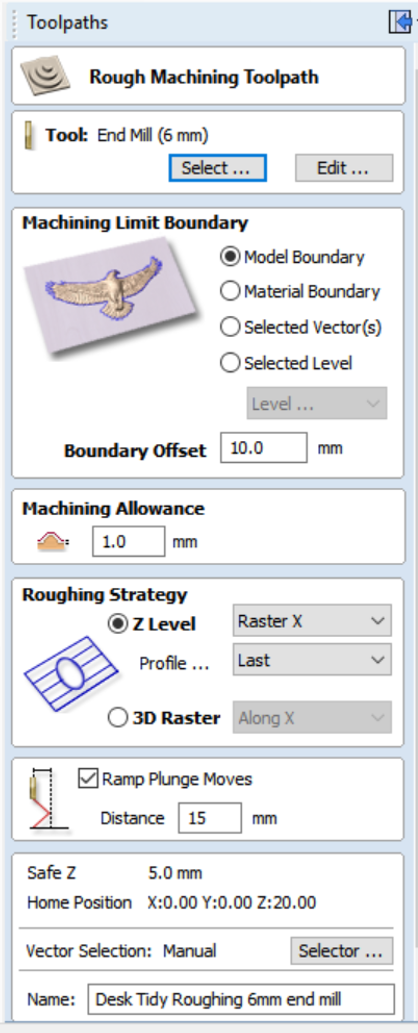

In Machine Limit Boundary, select Model Boundary and enter 10mm in Boundary Offset. (With this setting, the roughing toolpath will follow the 3D model’s outer contour for greater efficiency rather than clearing the whole block of material. The boundary offset allows it to clear an additional 10mm around the outer contour, allowing greater visibility and reducing the risk of the tool getting choked up in deep narrow channels.)

In Machining Allowance, set 1mm. (Machining allowance is the distance allowed for the roughing toolpath from the edge of the material. The additional 1mm will be cleared using a finishing toolpath.)

Set your roughing strategy as Z Level with the raster on X with a final profile toolpath run last to clear the outer boundary.

Select Ramp Plunge and set it to 15mm.

Name your toolpath using the usual naming convention + your initials. Your toolpath should be named Desk Tidy Roughing 6mm End Mill.

Select Calculate to complete your toolpath.

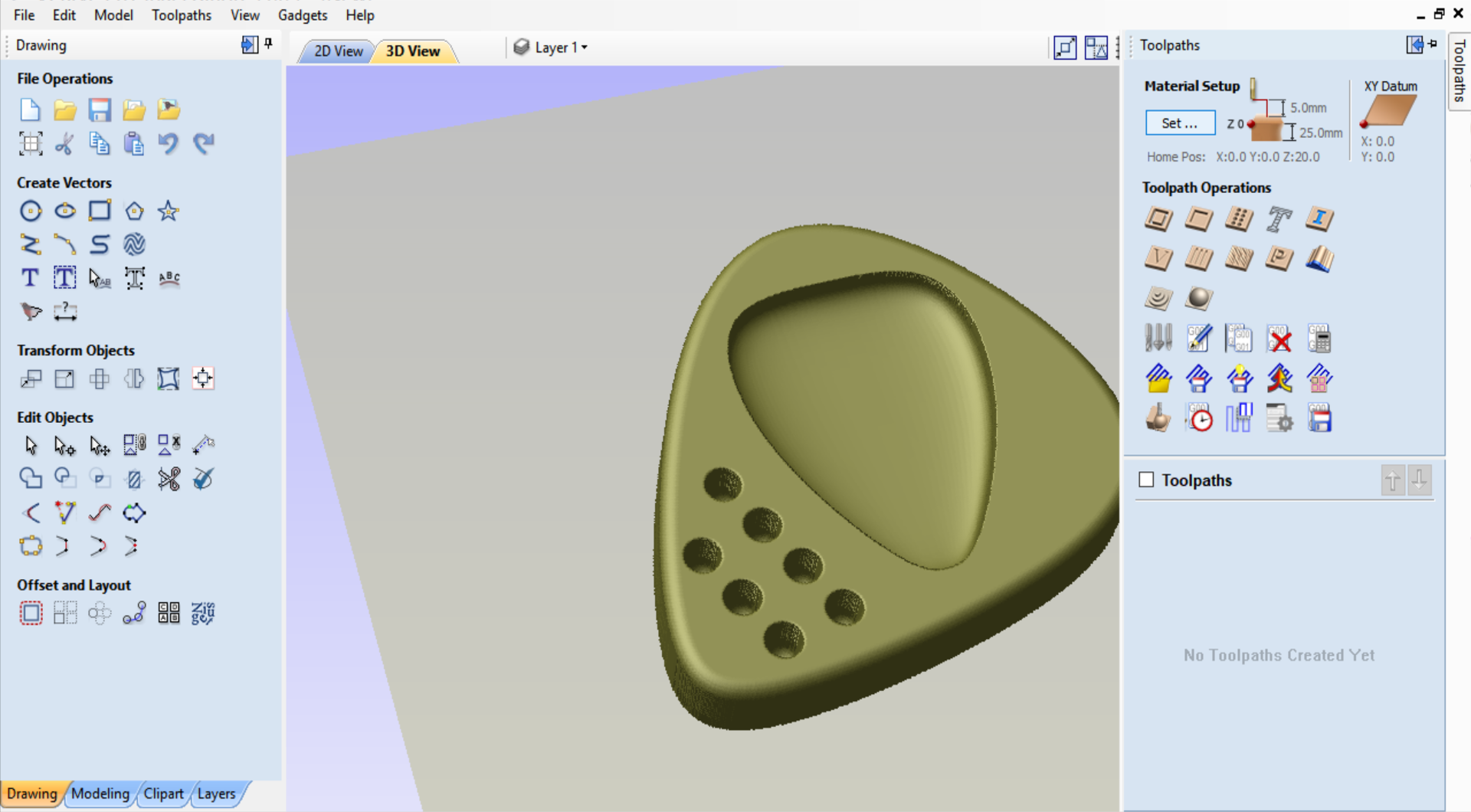

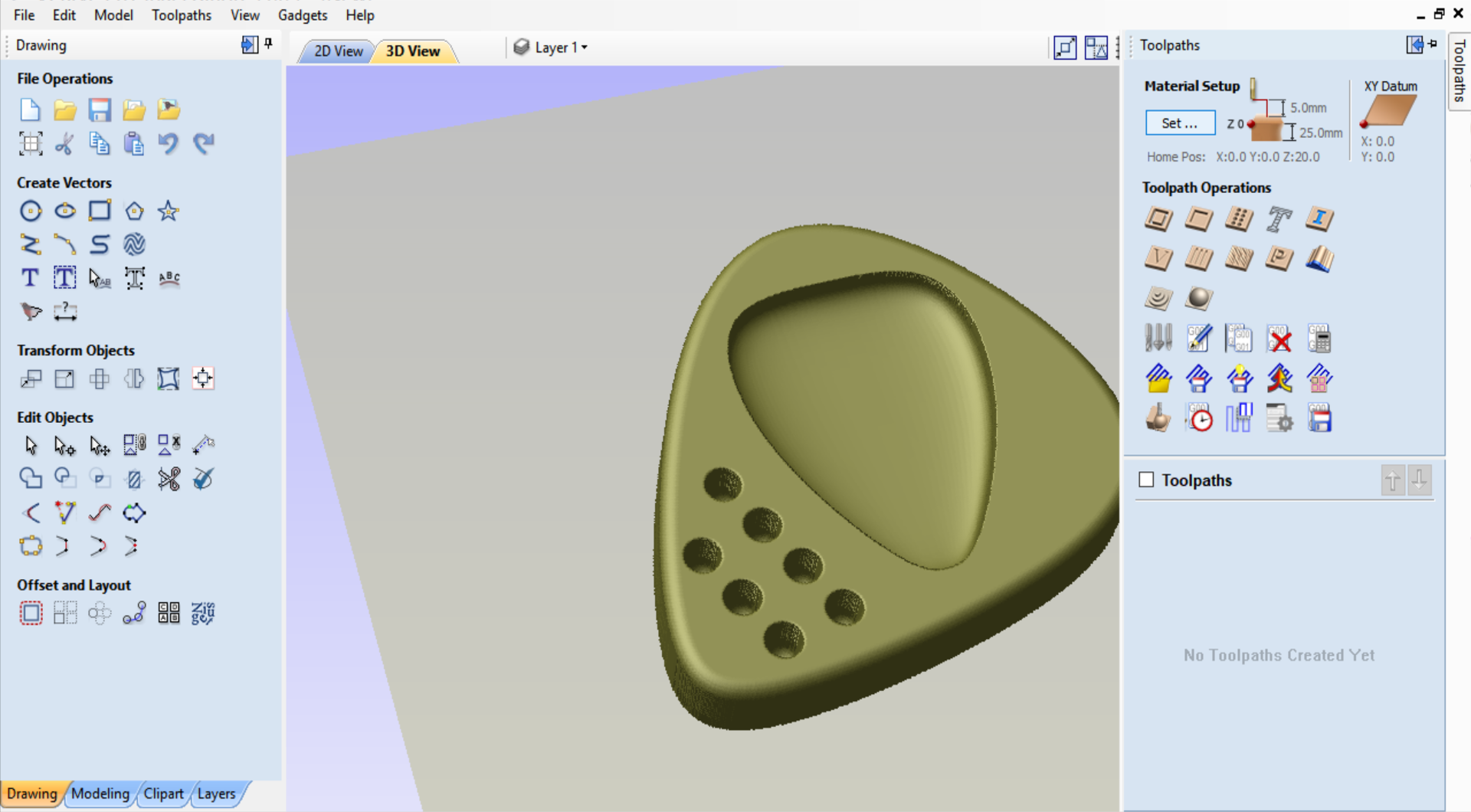

Step 1

Return to 3D view and go to the Toolpath bar on the right-hand side. Select Set… in Material Setup.

In Material Setup, go to Model Position in Material. Your material is 25mm thick whereas your 3D model is 20mm thick. To make sure that the 5mm difference gets milled off the top of your material, set a Gap Above Model of 5mm.

Select OK to save those settings.

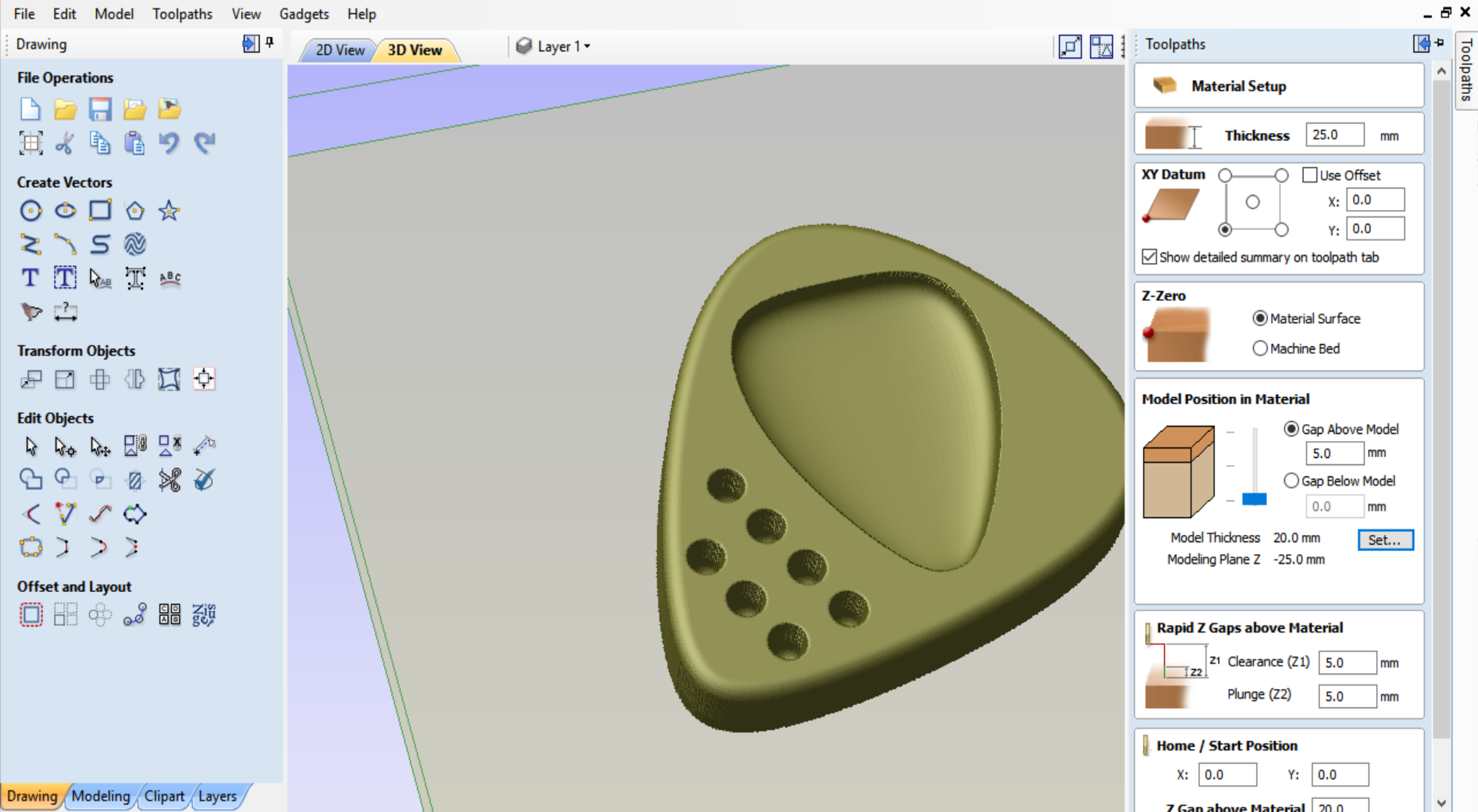

Step 2

You now want to create a roughing toolpath. A roughing toolpath in 3D milling is usually carried out with a larger cutter, often an end mill, to clear away as much material as possible from the workpiece before returning with a finer precision tool to run a finishing toolpath.Go to the Toolpaths tab and select a 3D Roughing toolpath.

When the Rough Machining Toolpath menu opens, go to Tool and Select to choose your cutter and settings.

In the Tool List, go to Metric Tools and select the 6mm End Mill, then enter the following settings:

In Cutting Parameters

- Pass Depth = 6mm

- Stepover = 40%

In Feeds and Speeds

- Spindle Speed = 15000 rpm

- Feed Rate = 3.6m/min

- Plunge Rate = 1.2m/min

Once you’ve entered these settings, select Apply and OK to return to your Rough Machining Toolpath settings.

Step 3

In the Rough Machining Toolpath menu, select the following settings:

In Machine Limit Boundary, select Model Boundary and enter 10mm in Boundary Offset. (With this setting, the roughing toolpath will follow the 3D model’s outer contour for greater efficiency rather than clearing the whole block of material. The boundary offset allows it to clear an additional 10mm around the outer contour, allowing greater visibility and reducing the risk of the tool getting choked up in deep narrow channels.)

In Machining Allowance, set 1mm. (Machining allowance is the distance allowed for the roughing toolpath from the edge of the material. The additional 1mm will be cleared using a finishing toolpath.)

Set your roughing strategy as Z Level with the raster on X with a final profile toolpath run last to clear the outer boundary.

Select Ramp Plunge and set it to 15mm.

Name your toolpath using the usual naming convention + your initials. Your toolpath should be named Desk Tidy Roughing 6mm End Mill.

Select Calculate to complete your toolpath.