Course navigation

-

Unit 1 - Create a 2D Design

Unit 2 - Set up Toolpaths from a 2D Design

Unit 3 - Have a go at CNC Milling

1—Customise your design

2—Calibrate the materials settings

3—Output your cutting data

4—Checkpoint!

Unit 4 - Create a 3D file for CNC Milling

Unit 5 - Import your Files for 3D Milling

Unit 6 - Set up Toolpaths for 3D Milling

Calibrate the materials settings

In this lesson, you will familiarise yourself with the setup on the MDX-50 and learn to fix your material in position and calibrate your Z height and your origin on the XY axis.

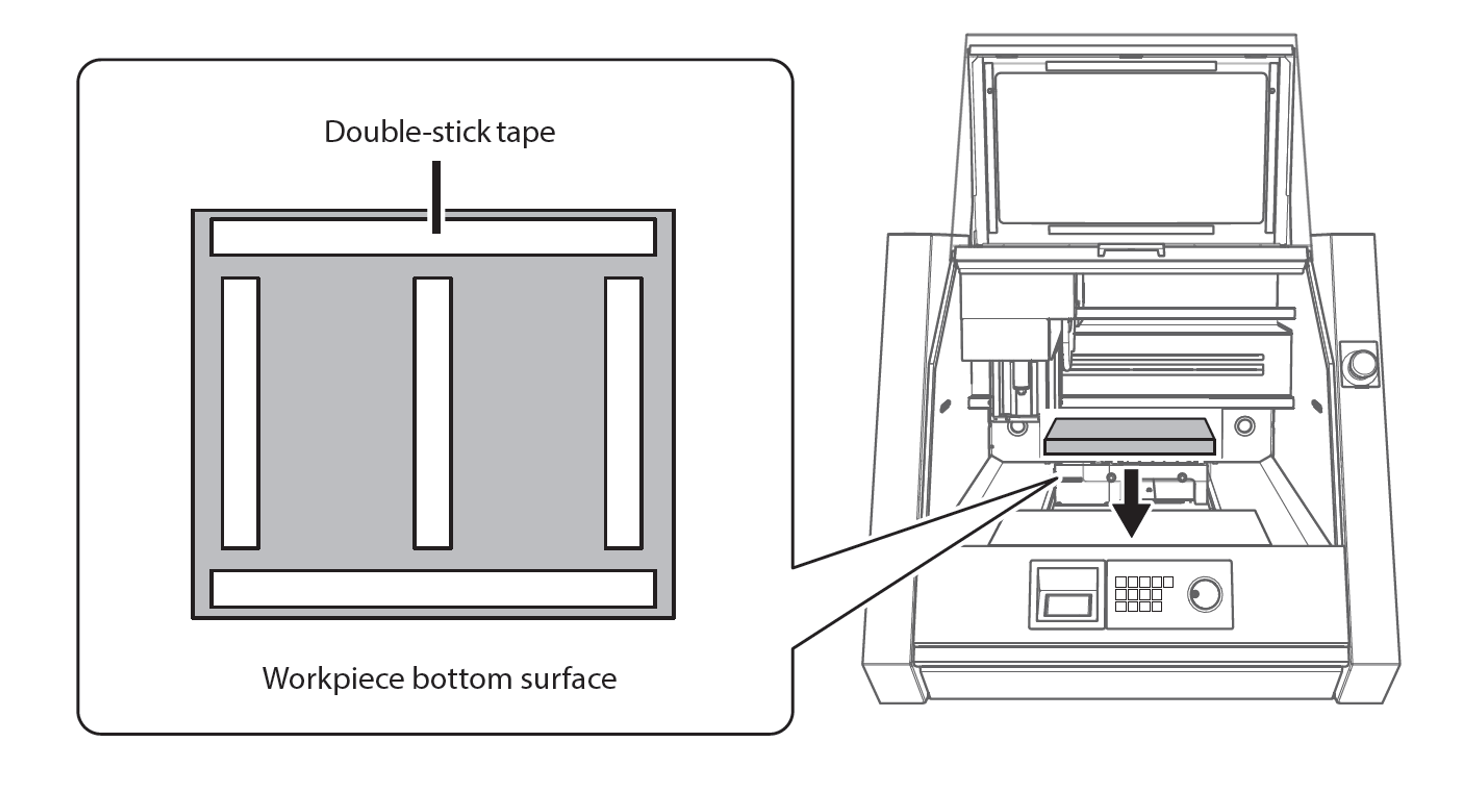

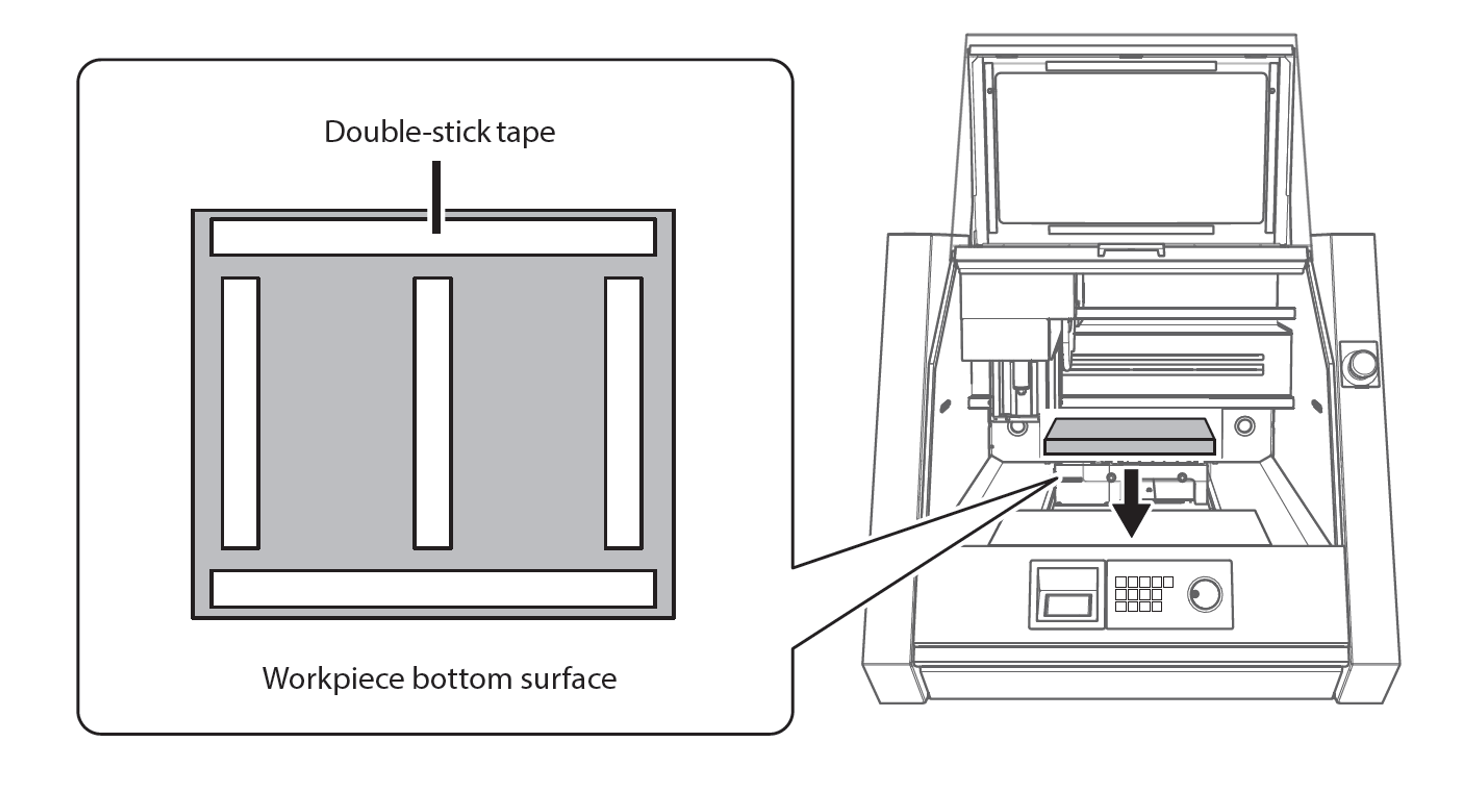

Your VCarve file is set up to cut a 300mm x 300mm board of 25mm necuron foam as provided for this workshop. Working in pairs, affix double sided tape to the base of the necuron board. You can now line it up to your sacrificial board on the XY axis to the bottom left corner of the sacrificial board.

Make sure that your material is properly fixed in place on all four sides with no movement.

To complete your setup, make sure that the VPanel icon is open on your desktop and that the following tools are loaded in the tool changer:

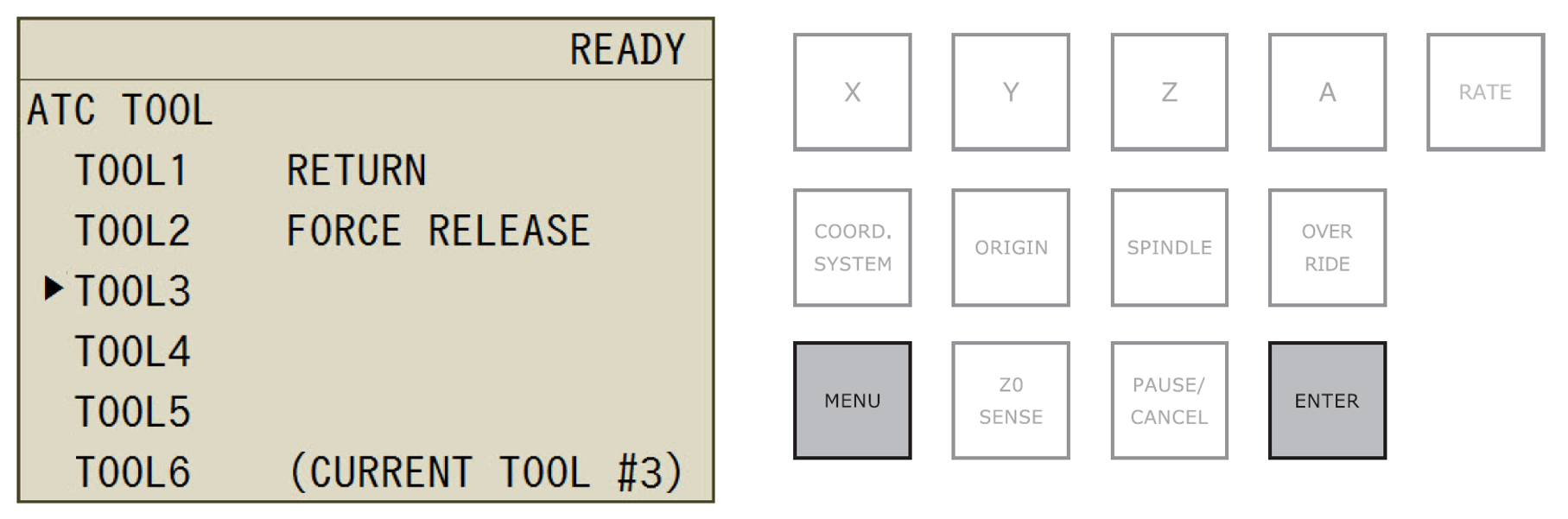

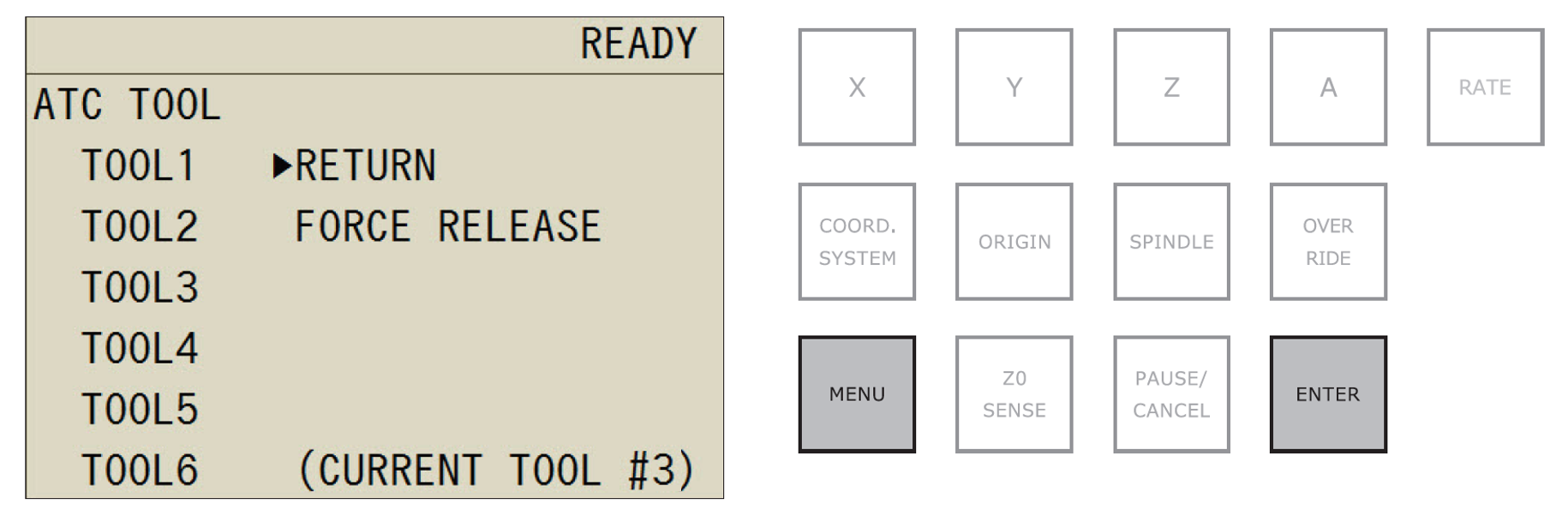

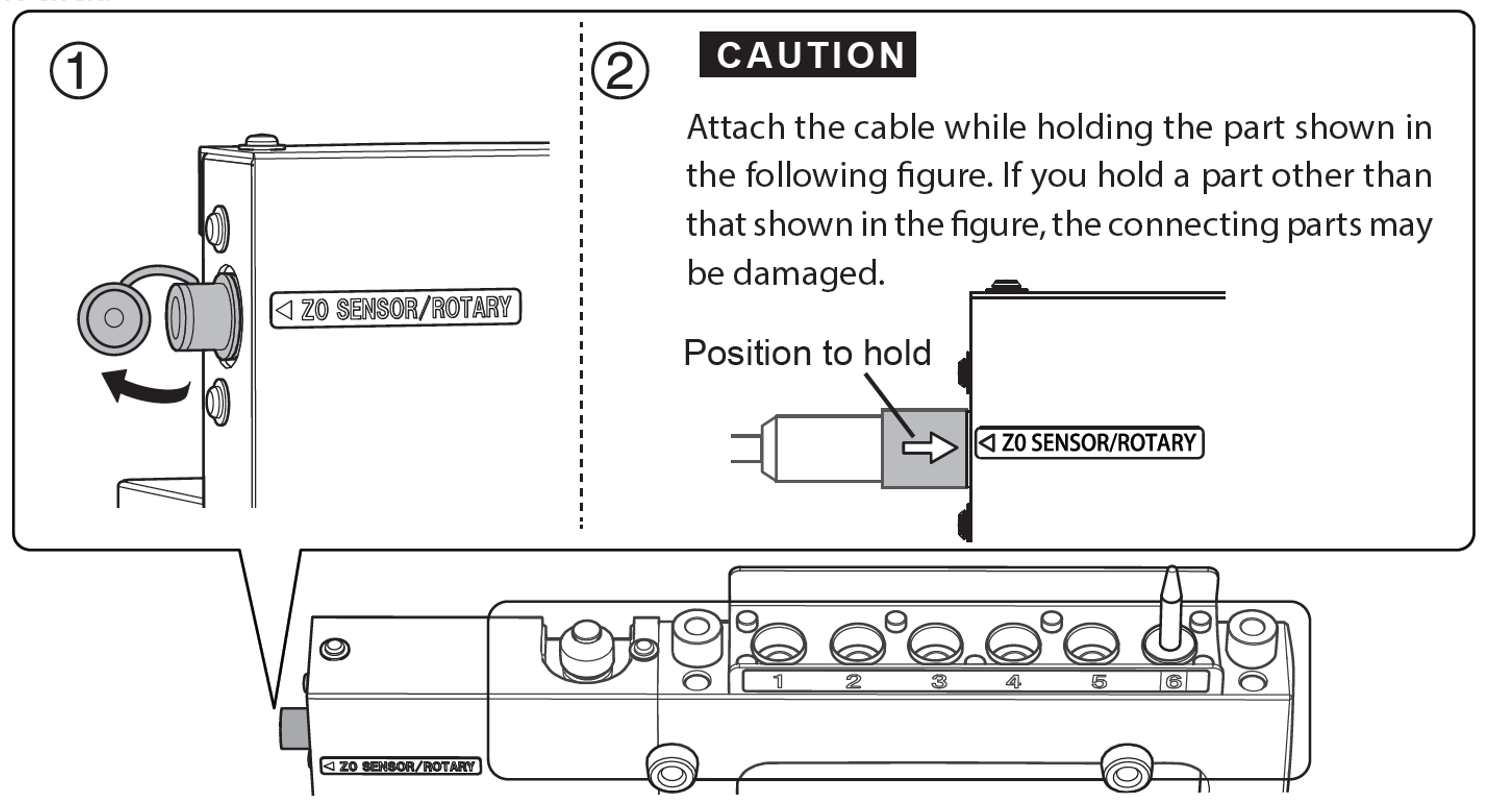

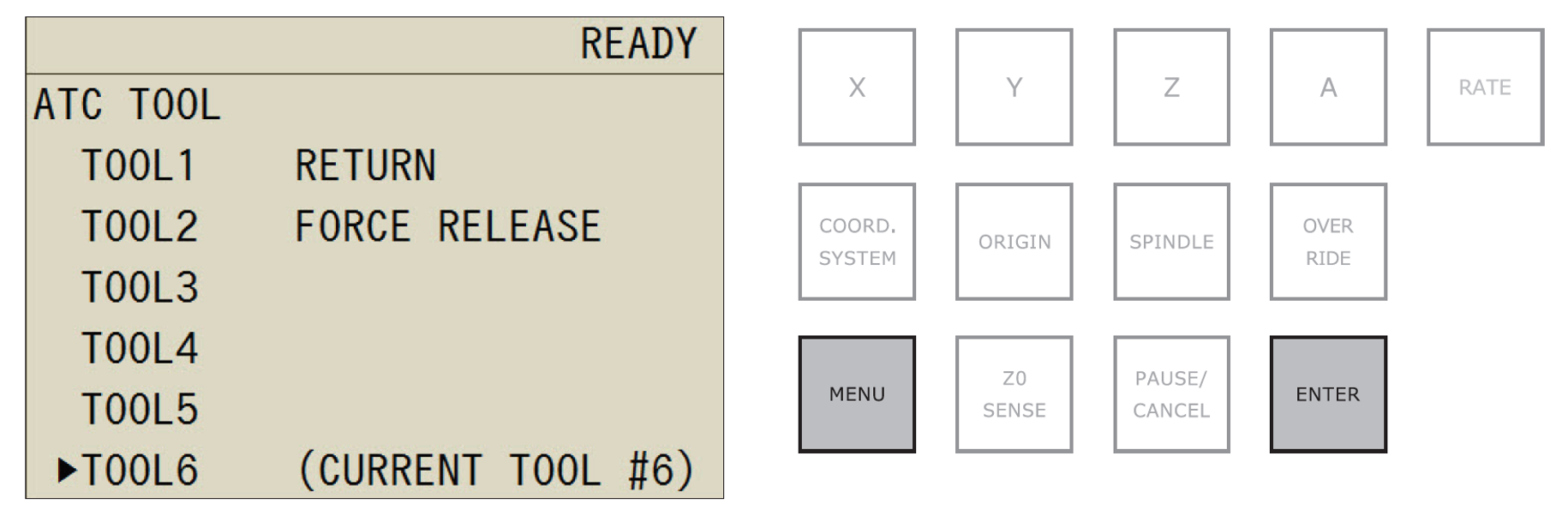

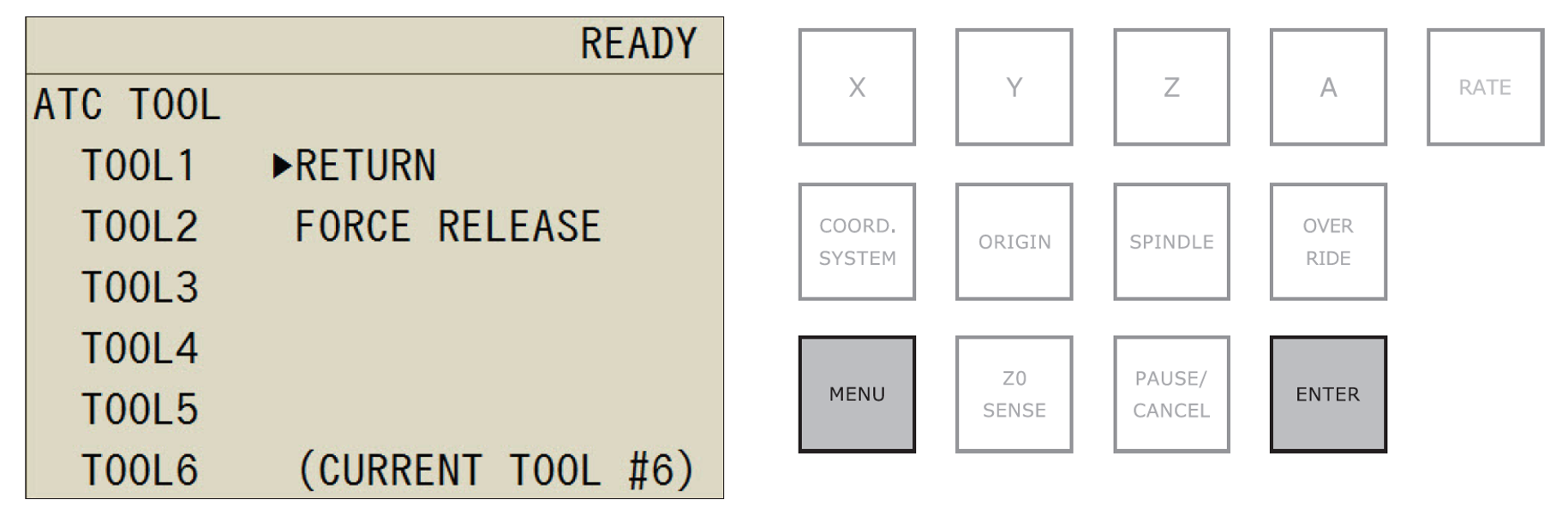

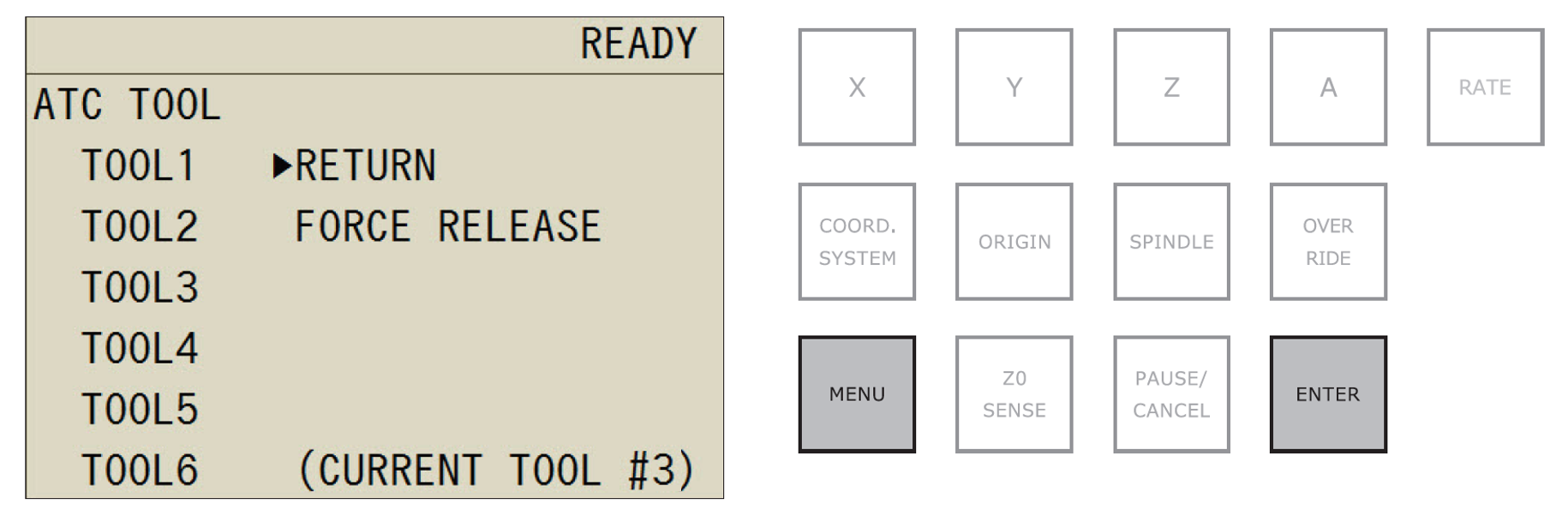

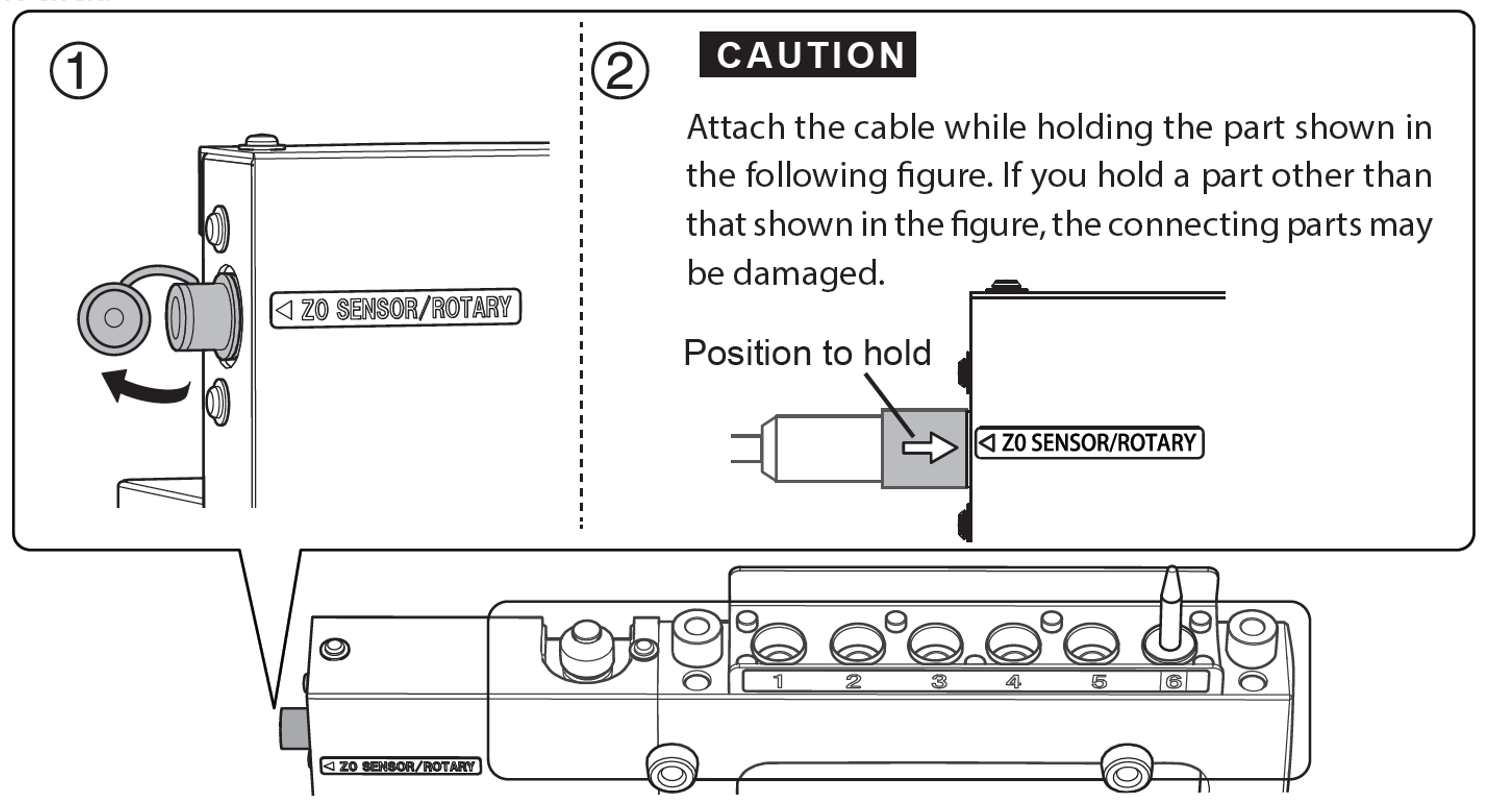

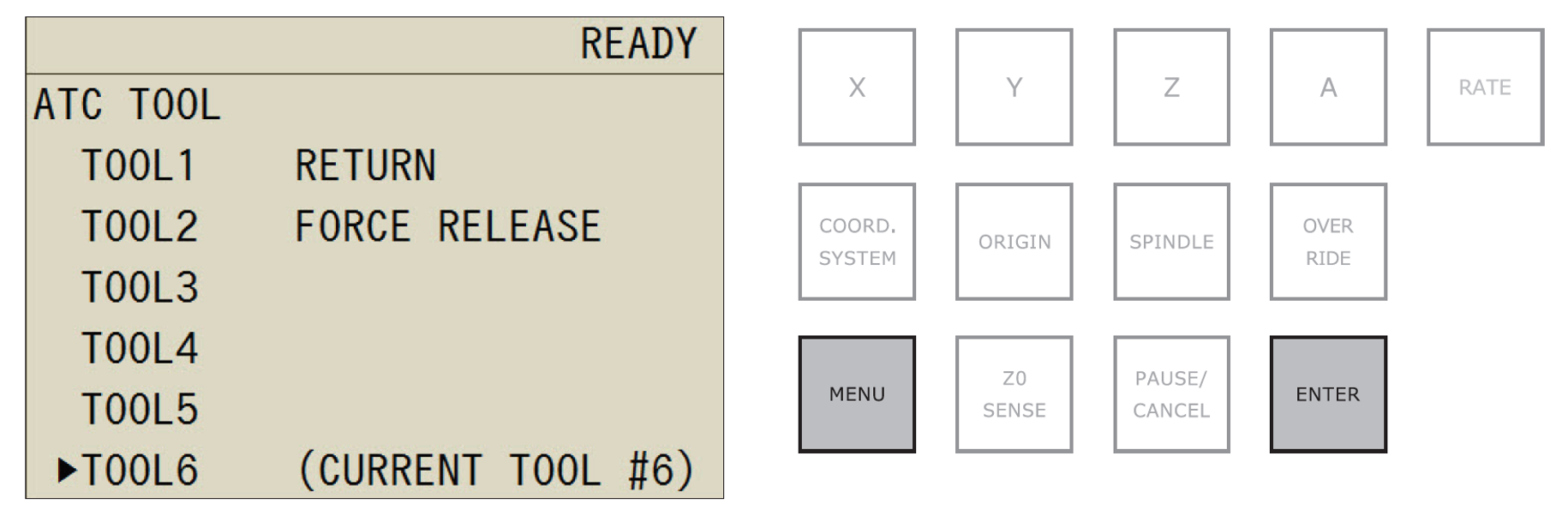

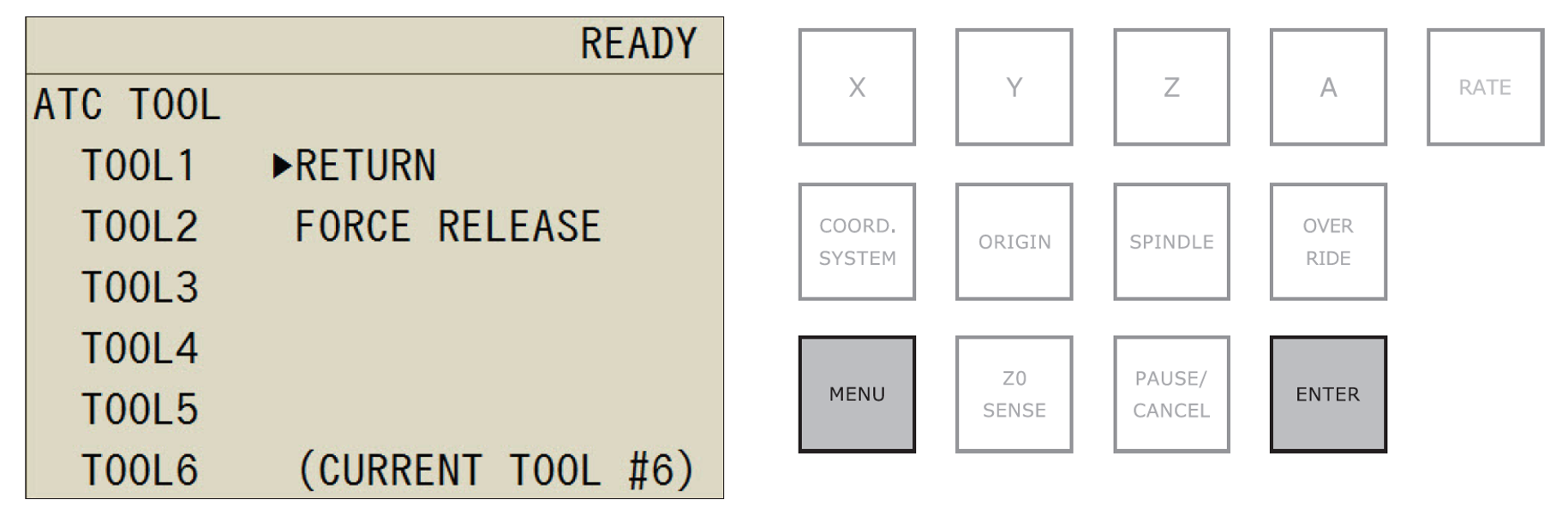

Press the Menu button several times until you reach the ATC Tools menu then use the scroll wheel to select the tool that you want. Select Tool 3 (6mm end mill) and press enter.

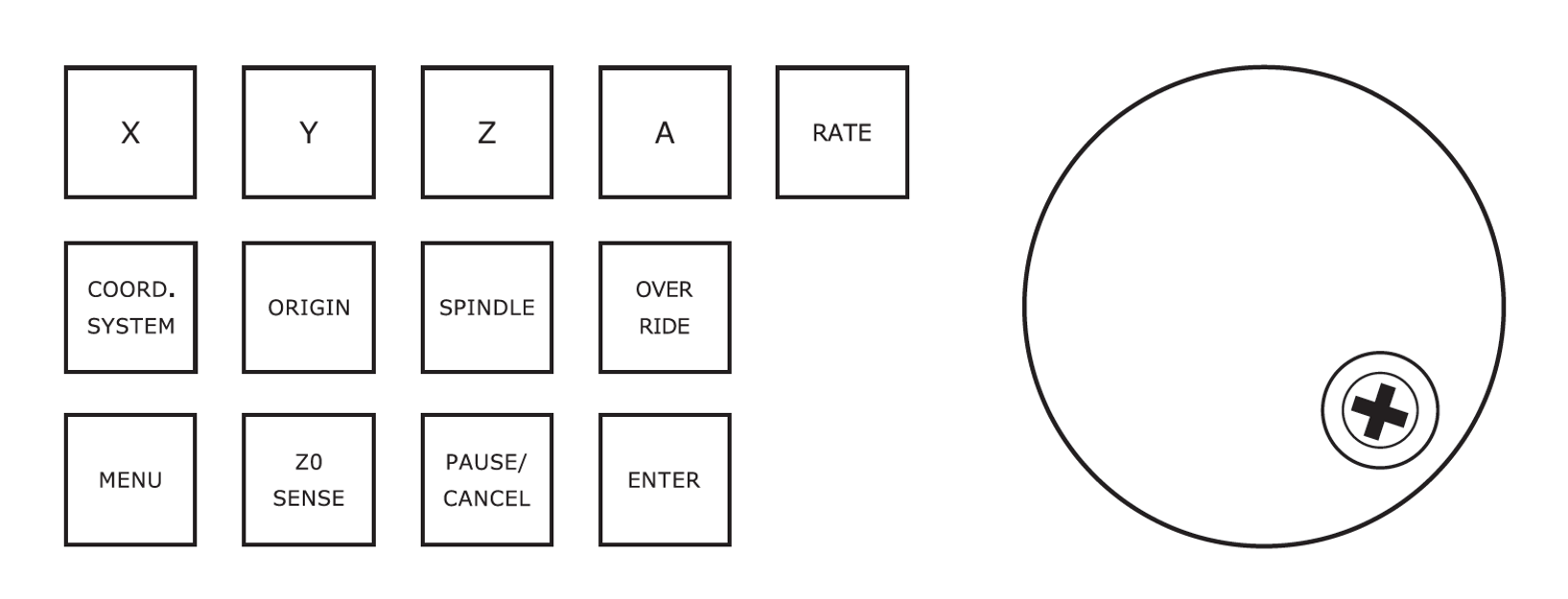

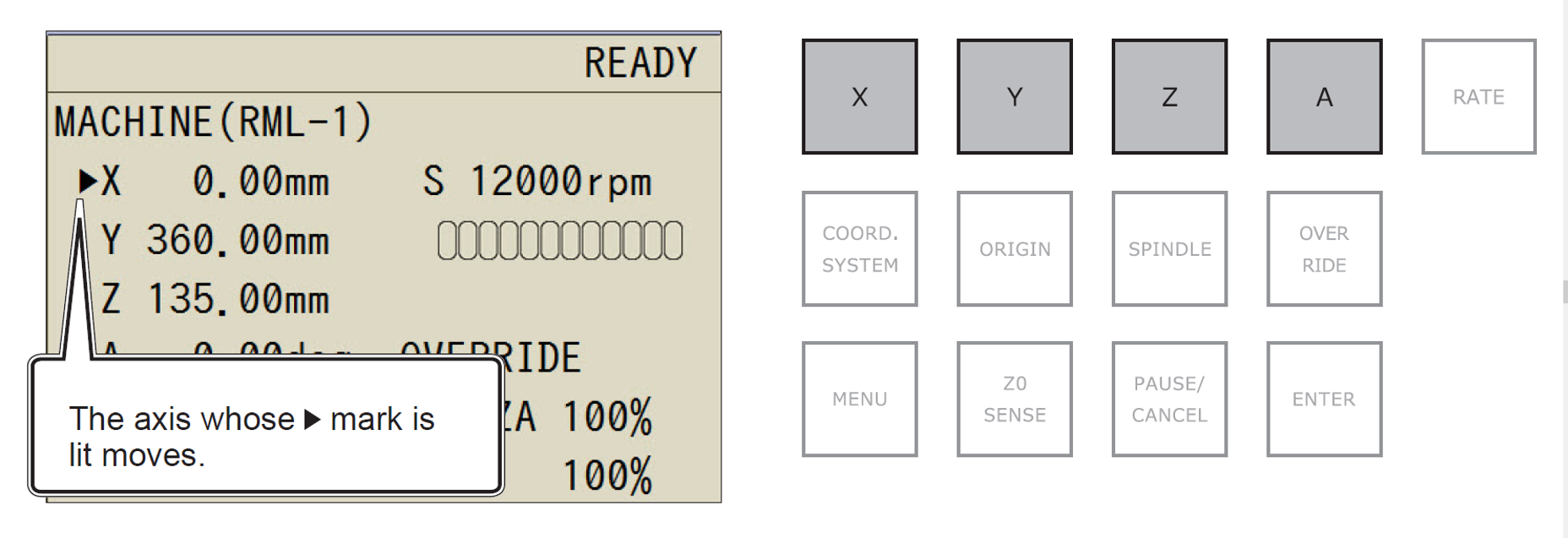

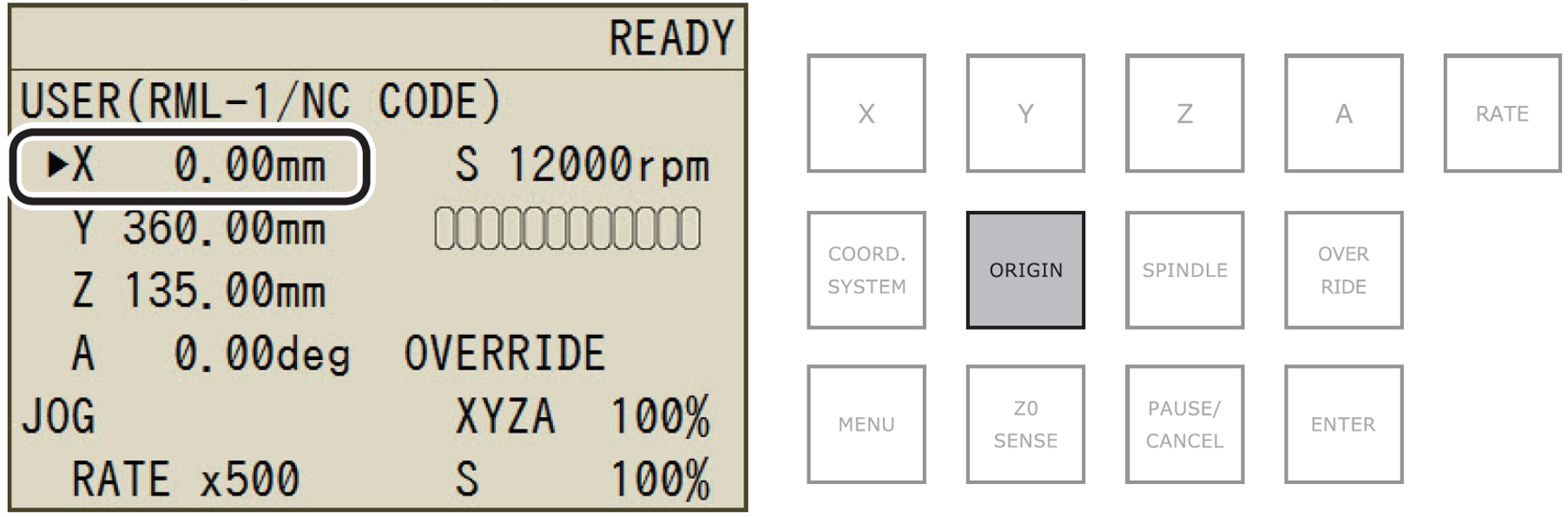

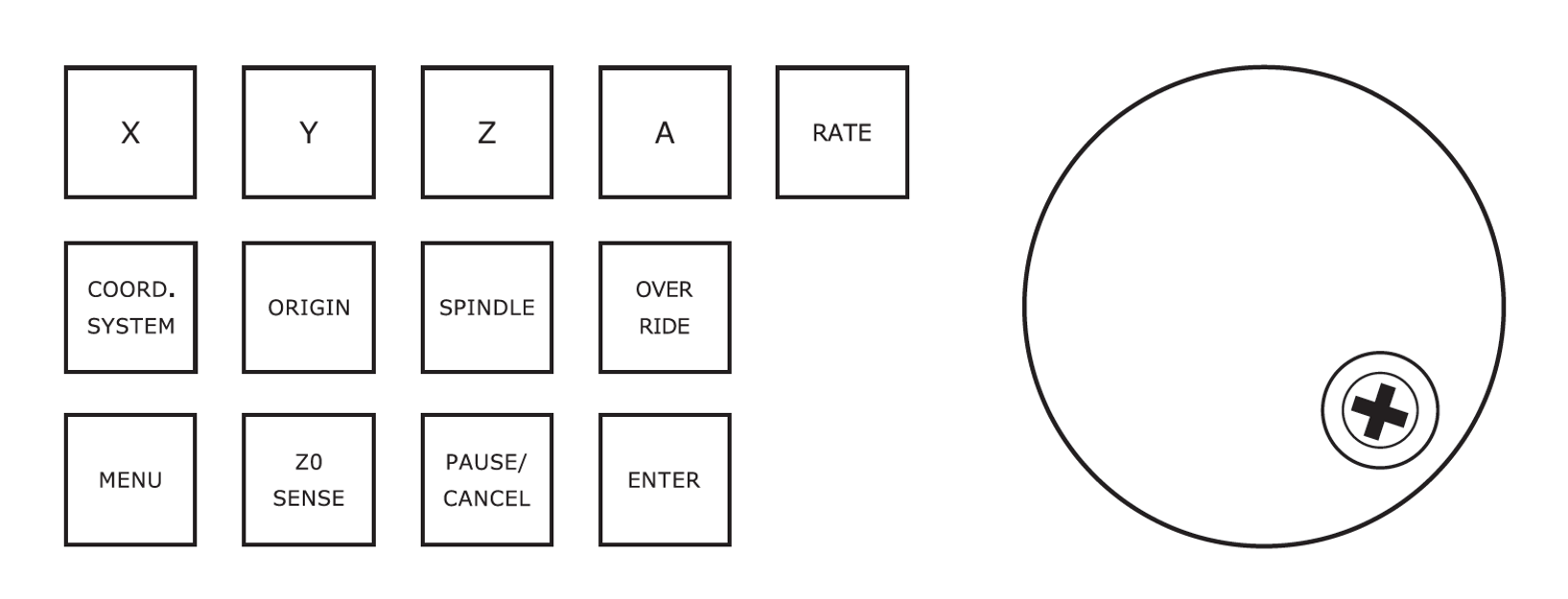

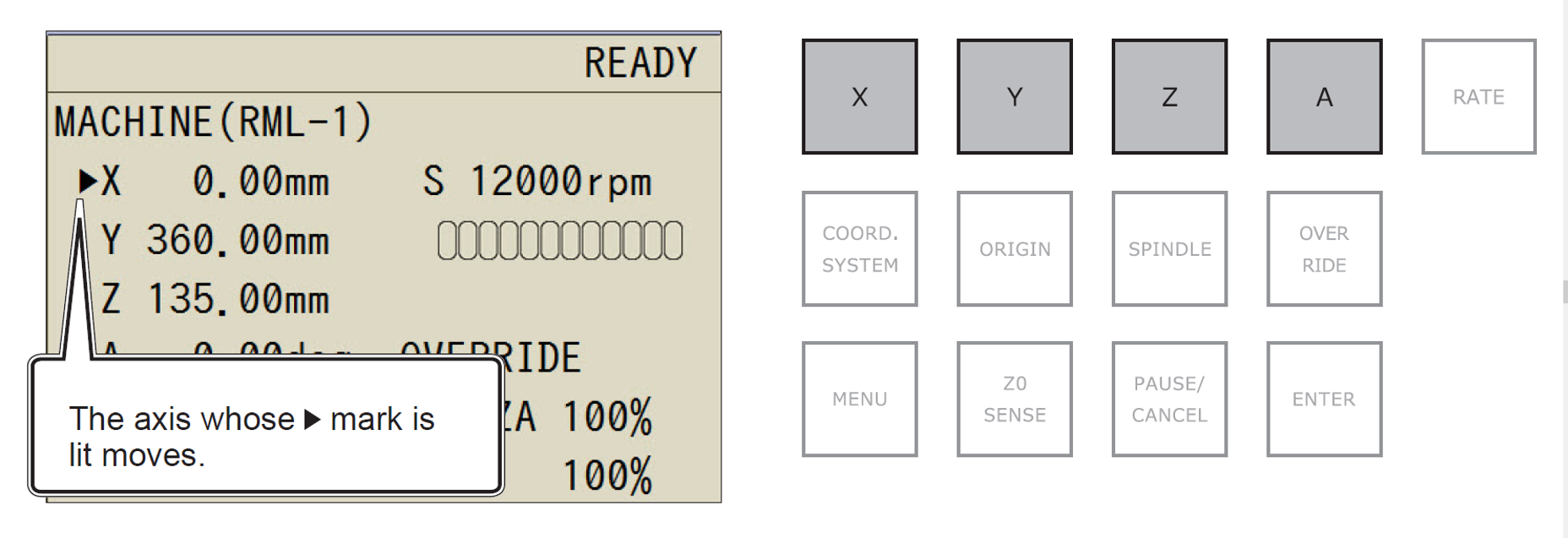

You now need to position your tool on your point of origin on the XY axis, which is the front right corner of your material. To move your tool into position, select the axis you wish to move on in the Built In Panel then move the tool in place using the scroll wheel.

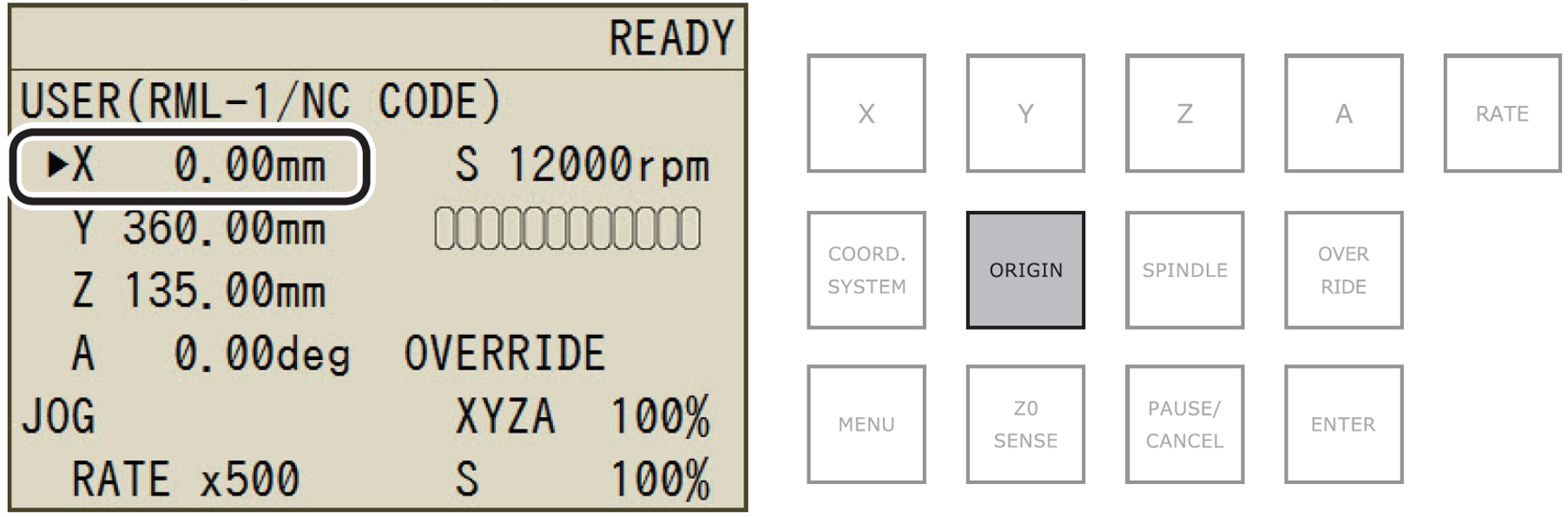

Once your tool is in the correct position (the centre of rotation of the tool should be lined up with the corner of the material), select X then select Origin in the Built In Panel to set it to zero. Repeat the same operation with Y. The coordinates for X and Y should now read 0,0.

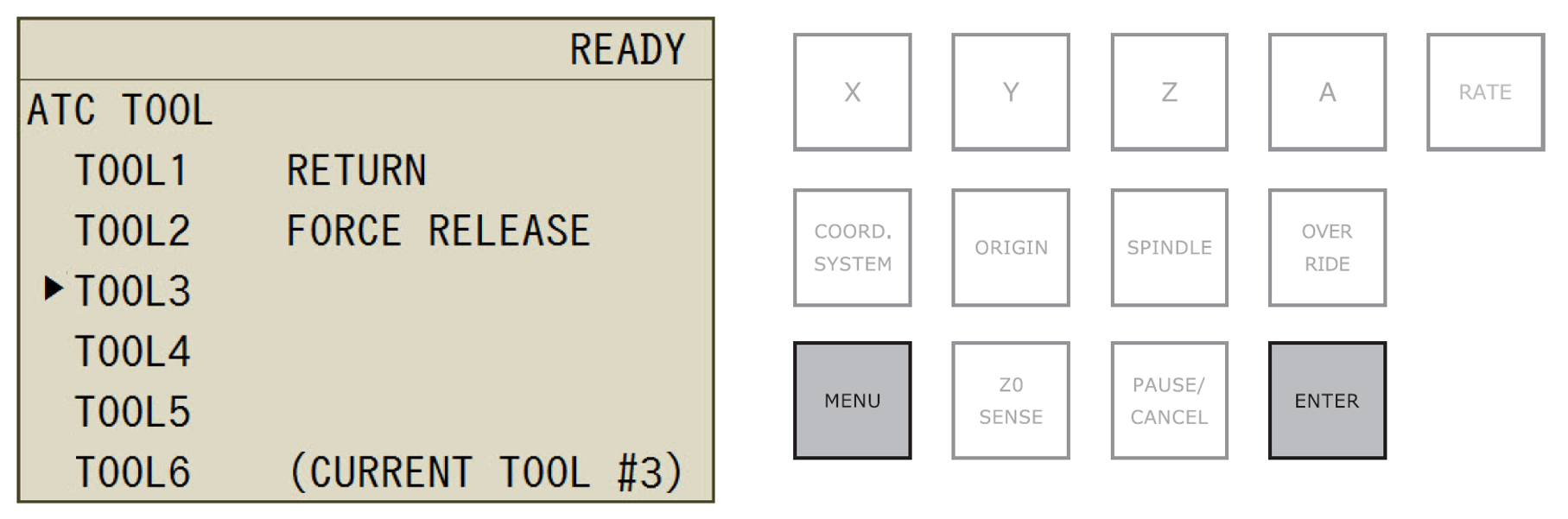

To return your tool to the tool holder, Go to Menu and ATC Tools. Tool 3 will be highlighted as in use. Use the scroll wheel to select RETURN and your tool will be returned to its holder.

To return your tool to the tool holder, Go to Menu and ATC Tools. Tool 3 will be highlighted as in use. Use the scroll wheel to select RETURN and your tool will be returned to its holder.

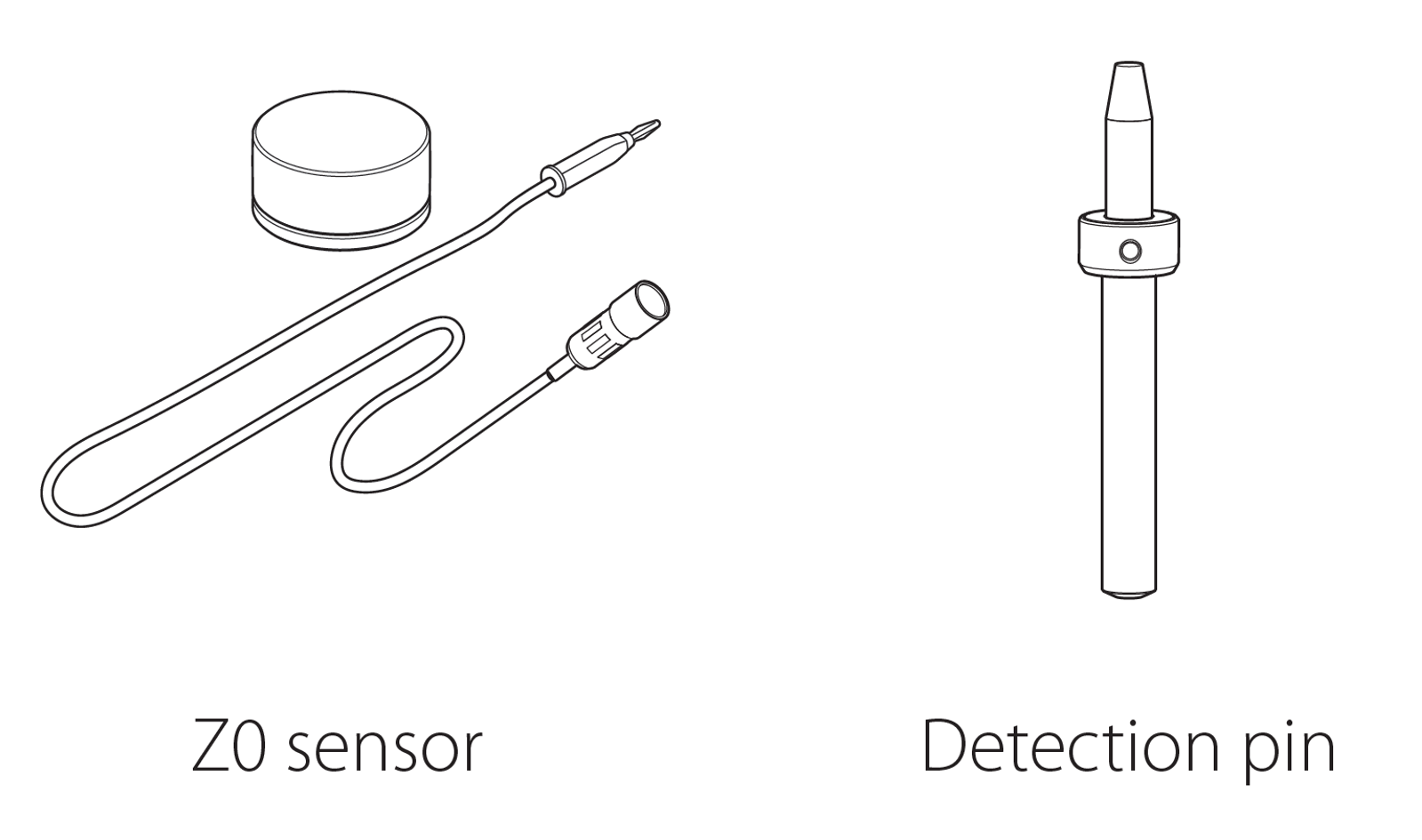

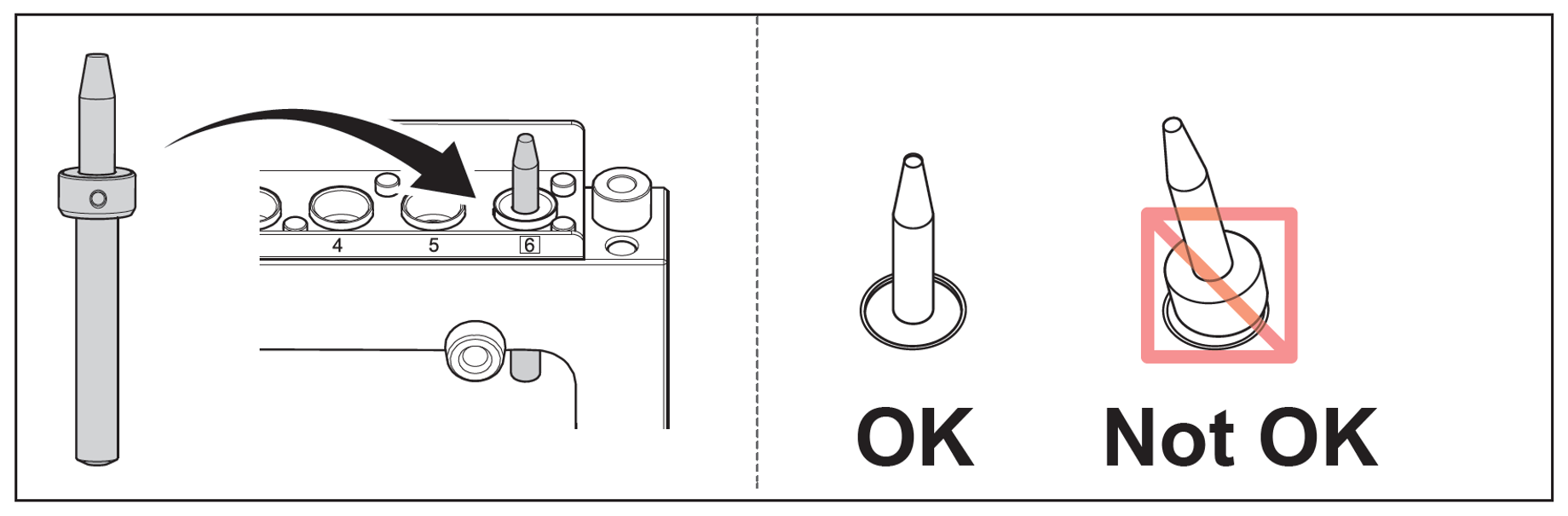

Check that the detection pin is loaded properly in the tool holder under Tool 6.

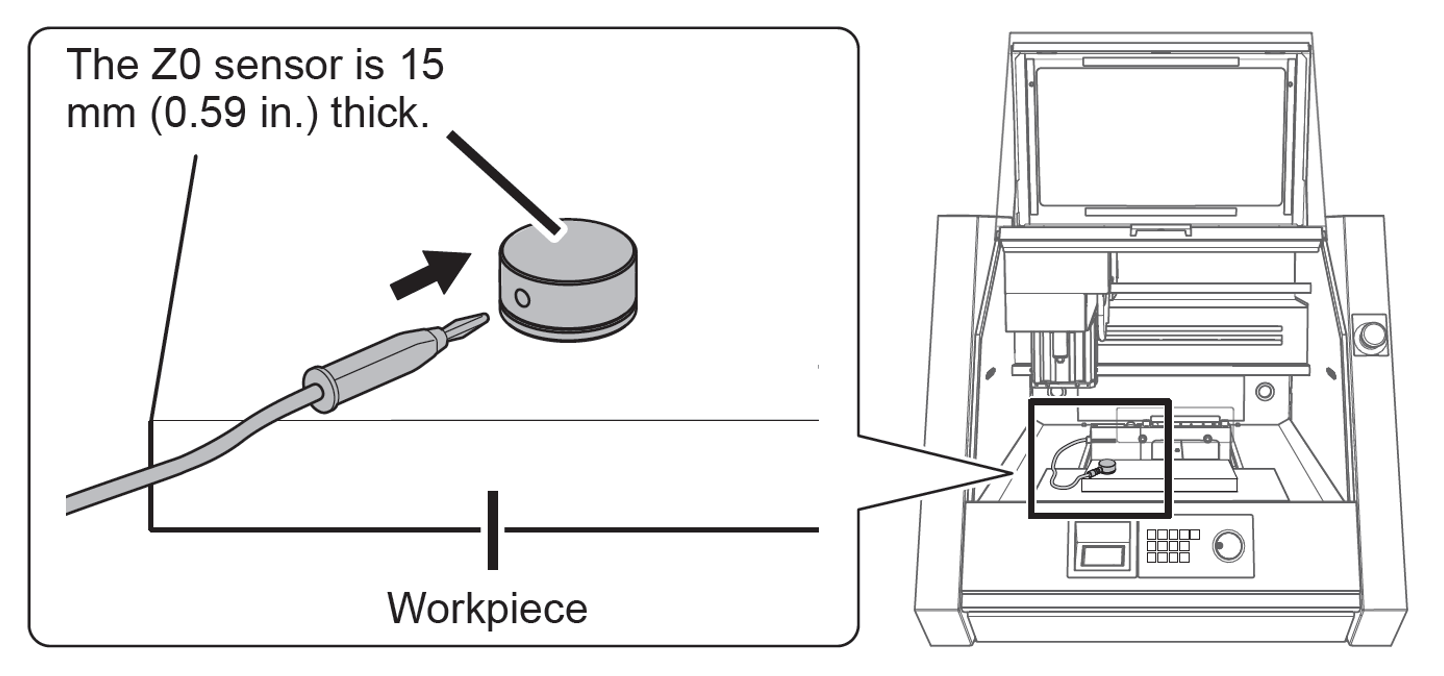

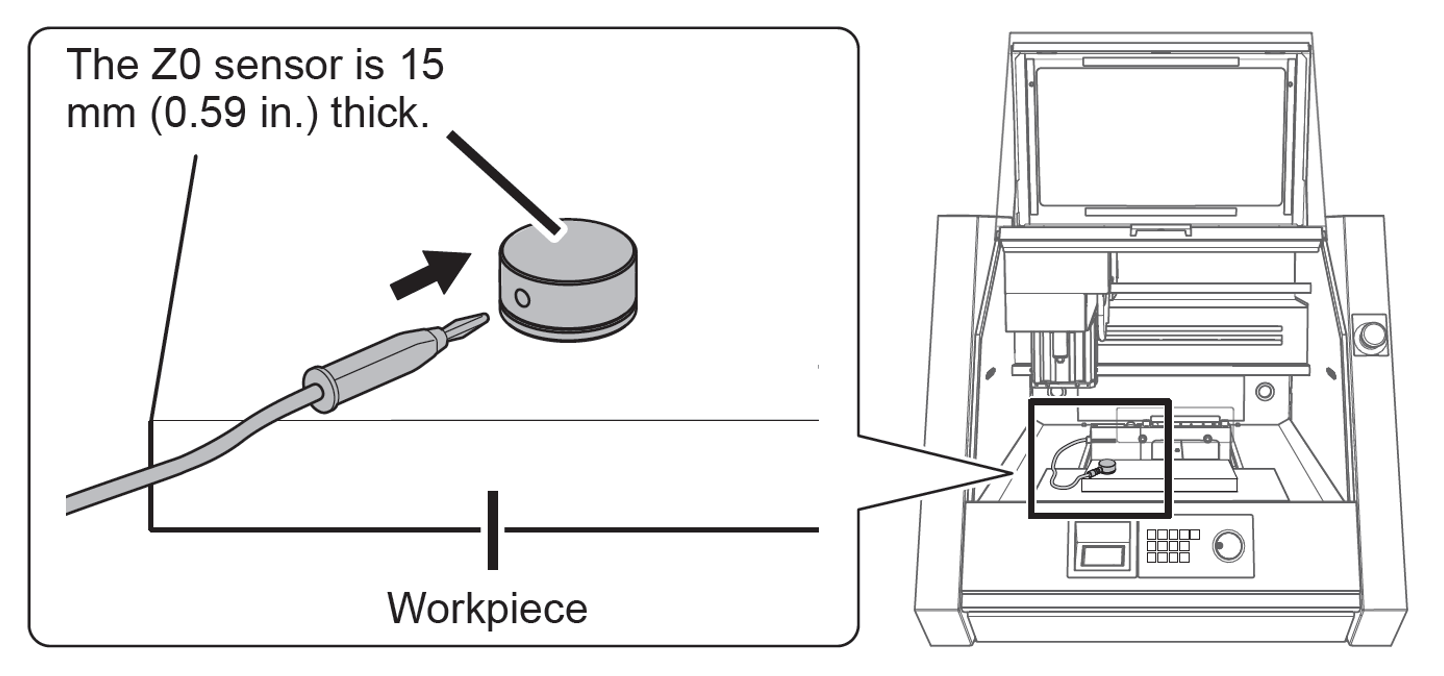

Check that the sensor is connected and position it on the centre of your material.

Go to Menu and ATC Tools and select the detection pin in Tool 6.

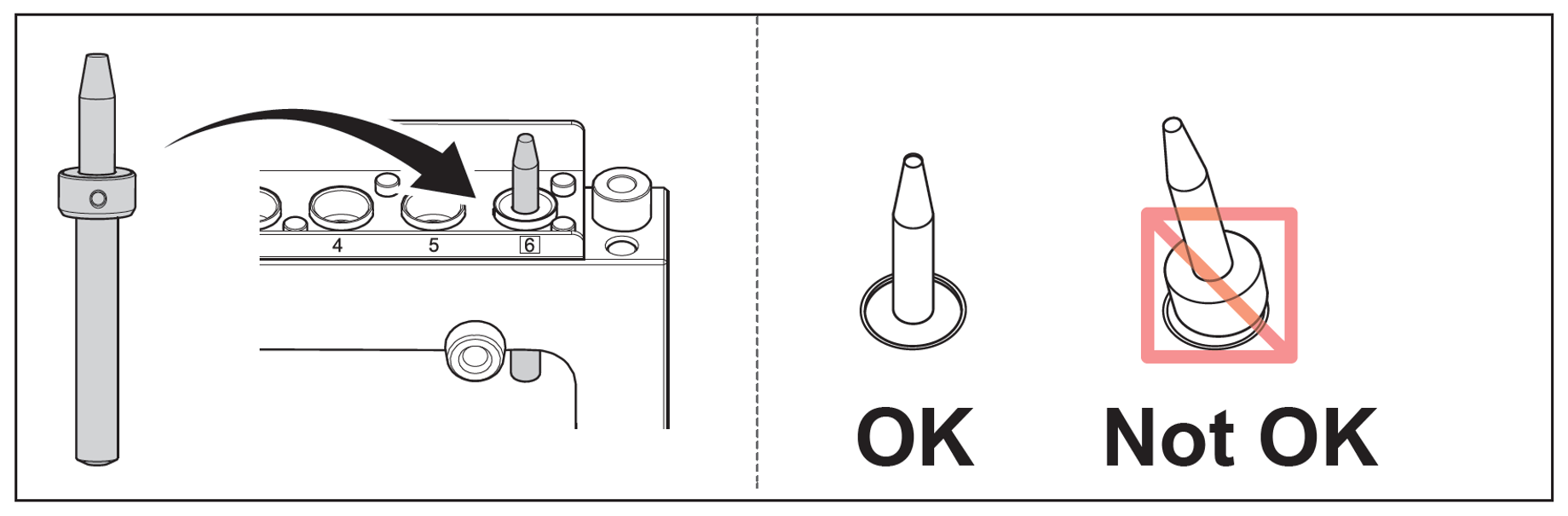

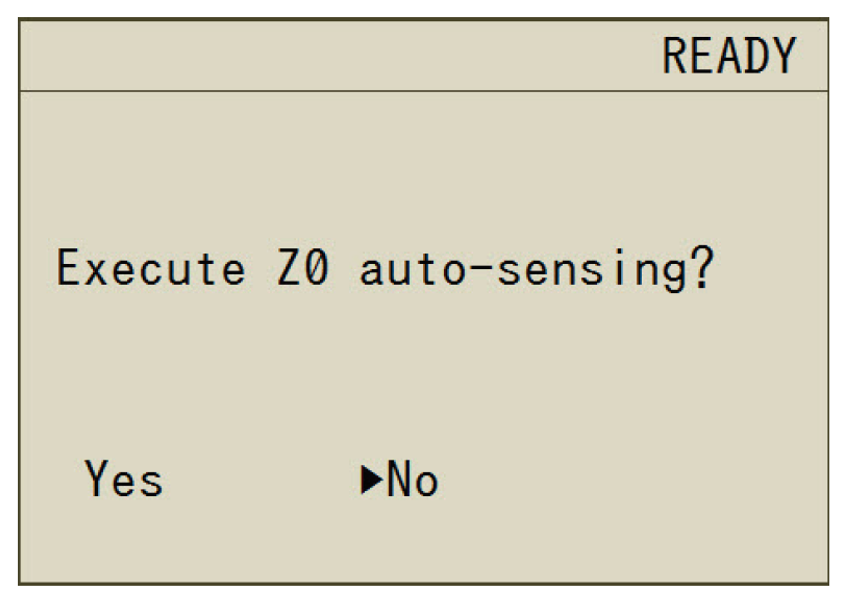

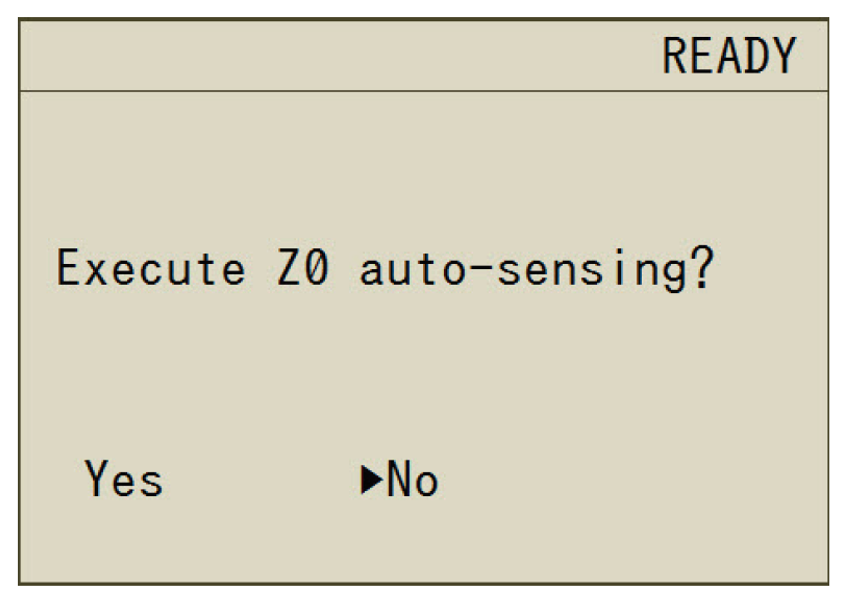

Use the X, Y, Z commands in the Built In Panel to move the detection pin until it is hovering approximately 10mm above the Z0 sensor. Once in position, press the command Z0 sensor. A dialogue box will open to ask you if you want to execute Z0 sensing, select YES using the scroll wheel. Please note: Never carry out Z0 sensing without the pin and sensor in position.

Once your Z origin has been set using the Z0 sensor, remove the sensor from the workspace and go to ATC Tools in Menu to return the sensing pin.

Congratulations, your machine settings are complete and you are now ready to output your toolpaths.

Step 1

The MDX-50 is set up with a sacrificial board to allow toolpaths to cut through materials without damaging the equipment.Your VCarve file is set up to cut a 300mm x 300mm board of 25mm necuron foam as provided for this workshop. Working in pairs, affix double sided tape to the base of the necuron board. You can now line it up to your sacrificial board on the XY axis to the bottom left corner of the sacrificial board.

Make sure that your material is properly fixed in place on all four sides with no movement.

To complete your setup, make sure that the VPanel icon is open on your desktop and that the following tools are loaded in the tool changer:

- Tool 1 = 3mm end mill

- Tool 2 = 6mm V-Bit 60 deg

- Tool 3 = 6mm end mill

- Tool 6 = Z0 Detection Pin

Step 2

Now that your material is fixed in place, you can set your XY origin using the Built In Panel.

Press the Menu button several times until you reach the ATC Tools menu then use the scroll wheel to select the tool that you want. Select Tool 3 (6mm end mill) and press enter.

You now need to position your tool on your point of origin on the XY axis, which is the front right corner of your material. To move your tool into position, select the axis you wish to move on in the Built In Panel then move the tool in place using the scroll wheel.

Once your tool is in the correct position (the centre of rotation of the tool should be lined up with the corner of the material), select X then select Origin in the Built In Panel to set it to zero. Repeat the same operation with Y. The coordinates for X and Y should now read 0,0.

To return your tool to the tool holder, Go to Menu and ATC Tools. Tool 3 will be highlighted as in use. Use the scroll wheel to select RETURN and your tool will be returned to its holder.

To return your tool to the tool holder, Go to Menu and ATC Tools. Tool 3 will be highlighted as in use. Use the scroll wheel to select RETURN and your tool will be returned to its holder.

Step 3

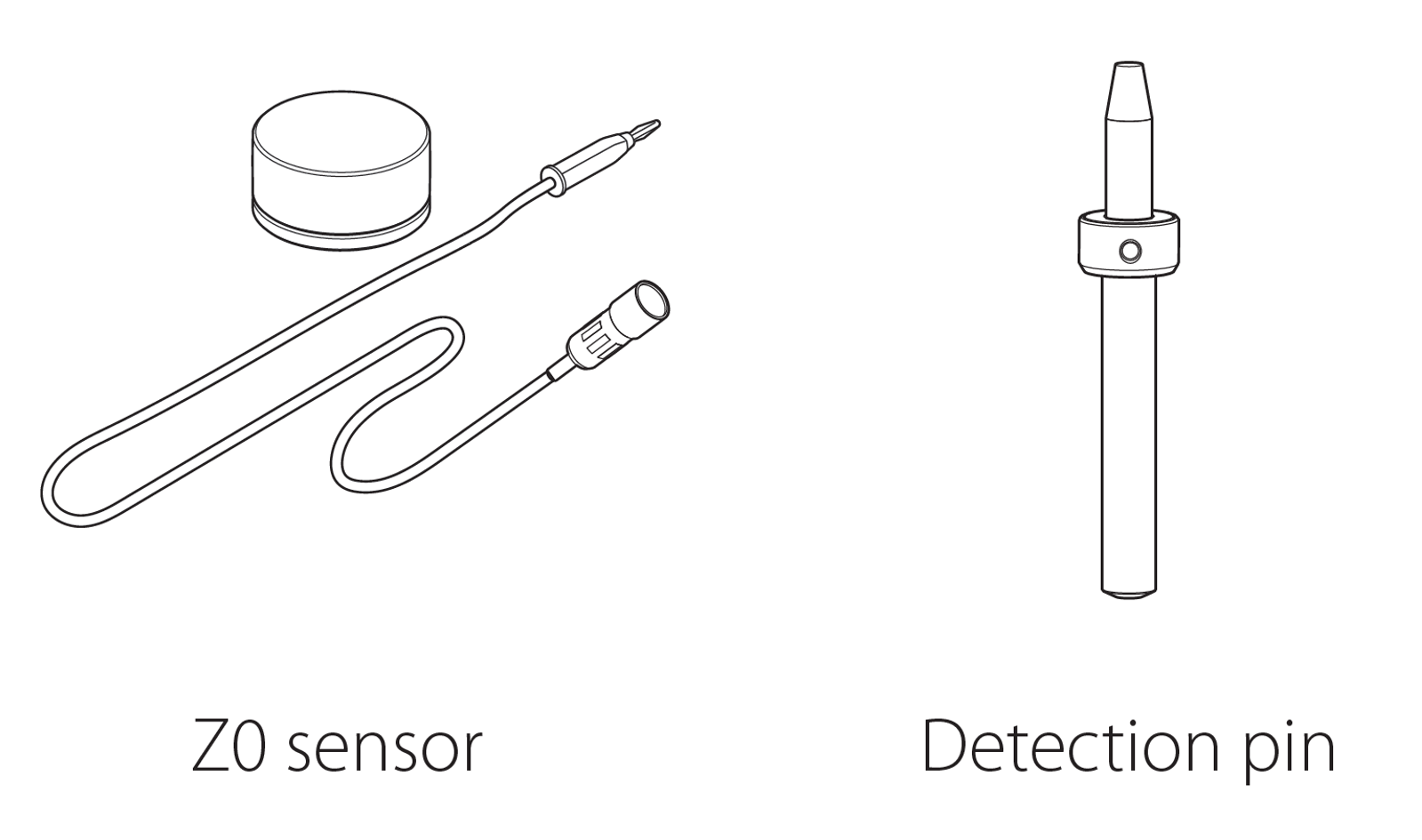

Now that you have set your XY origin, you can set your Z origin based on the top surface of the material. To do so, you will need the Z0 sensor and the detection pin.

Check that the detection pin is loaded properly in the tool holder under Tool 6.

Check that the sensor is connected and position it on the centre of your material.

Go to Menu and ATC Tools and select the detection pin in Tool 6.

Use the X, Y, Z commands in the Built In Panel to move the detection pin until it is hovering approximately 10mm above the Z0 sensor. Once in position, press the command Z0 sensor. A dialogue box will open to ask you if you want to execute Z0 sensing, select YES using the scroll wheel. Please note: Never carry out Z0 sensing without the pin and sensor in position.

Once your Z origin has been set using the Z0 sensor, remove the sensor from the workspace and go to ATC Tools in Menu to return the sensing pin.

Congratulations, your machine settings are complete and you are now ready to output your toolpaths.